Mounting processing operation device, operation method and display substrate module assembly line

A technology for operating devices and substrates, applied in nonlinear optics, optics, instruments, etc., can solve problems such as difficulty in improving the accuracy of substrate flatness, and achieve high yield or high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

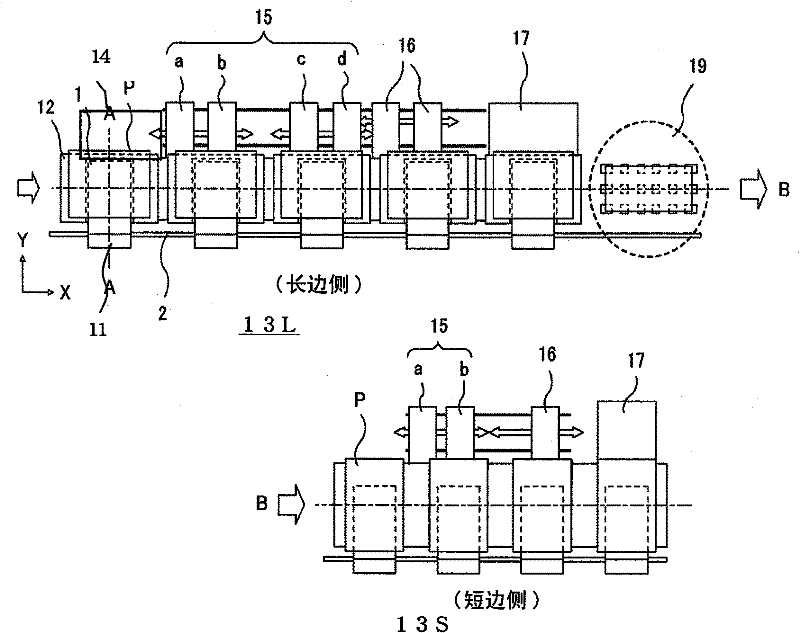

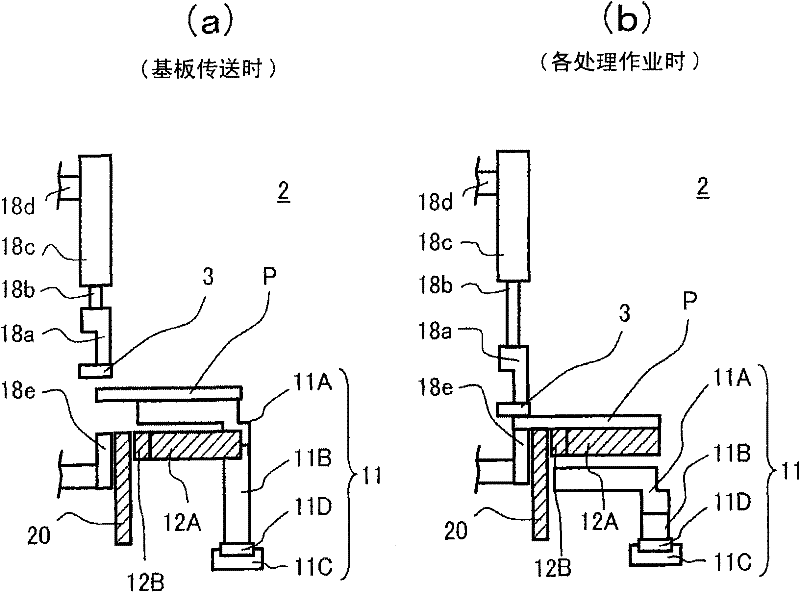

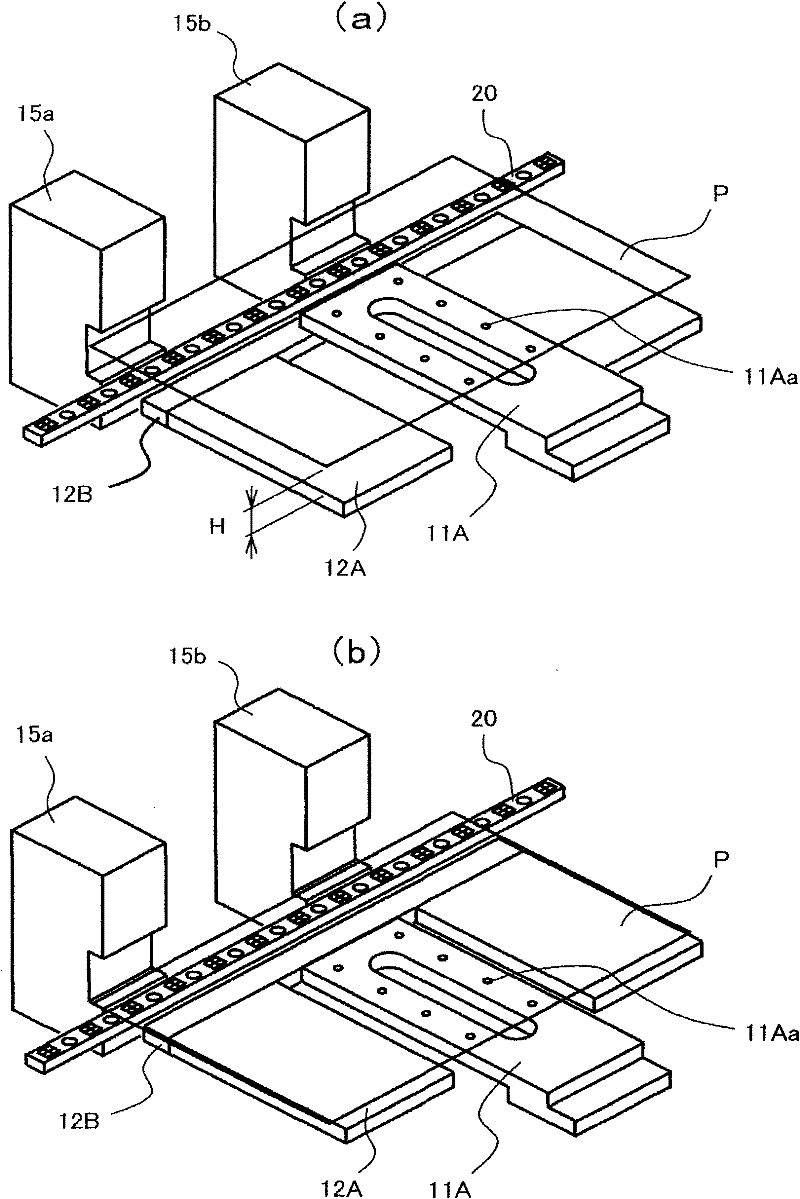

[0058] Below, use Figure 1 to Figure 11 One embodiment of the present invention will be described.

[0059] figure 1 is a diagram showing a display substrate module assembly line 1 according to an embodiment of the present invention, figure 2 It is a figure which shows the basic structure of the transfer apparatus 2 of this board|substrate.

[0060] figure 1 The device is a production line device that transfers substrates sequentially from left to right in the figure through a transfer device, and at the same time performs various processing operations on the peripheral parts of the substrates, and performs mounting and assembly operations such as ICs or TABs. The transfer device includes holding substrates P has a substrate holding mechanism 12 and a transfer arm 11 for transferring the substrate to an adjacent position where a processing device is installed. figure 1 The device of the above-mentioned device first performs the processing on the long side of the substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com