Solid electrolyte tantalum-niobium composite capacitor and preparation method thereof

A composite capacitor, solid electrolyte technology, used in solid electrolytic capacitors, electrolytic capacitors, capacitors and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a solid electrolyte niobium-tantalum composite capacitor. The niobium-tantalum composite capacitor is prepared by mixing niobium and tantalum. First, tantalum powder and niobium powder or tantalum powder and pure niobium monoxide are mixed uniformly in a certain proportion, wherein the tantalum content is 5% to 95%, and the remaining content is niobium; then it is pressed and formed to obtain a composite metal anode block, and then vacuum sintered to obtain the anode of the composite capacitor. After electrochemical oxidation, a dielectric film of composite tantalum oxide and niobium oxide is formed to become the anode of the niobium-tantalum composite capacitor, and the cathode is made of solid manganese dioxide. The appearance of the product is similar to that of a chip-type solid electrolyte niobium-tantalum composite capacitor. The preparation method includes the steps of mixing, molding, sintering, energizing, and coating of tantalum powder an...

Embodiment 2

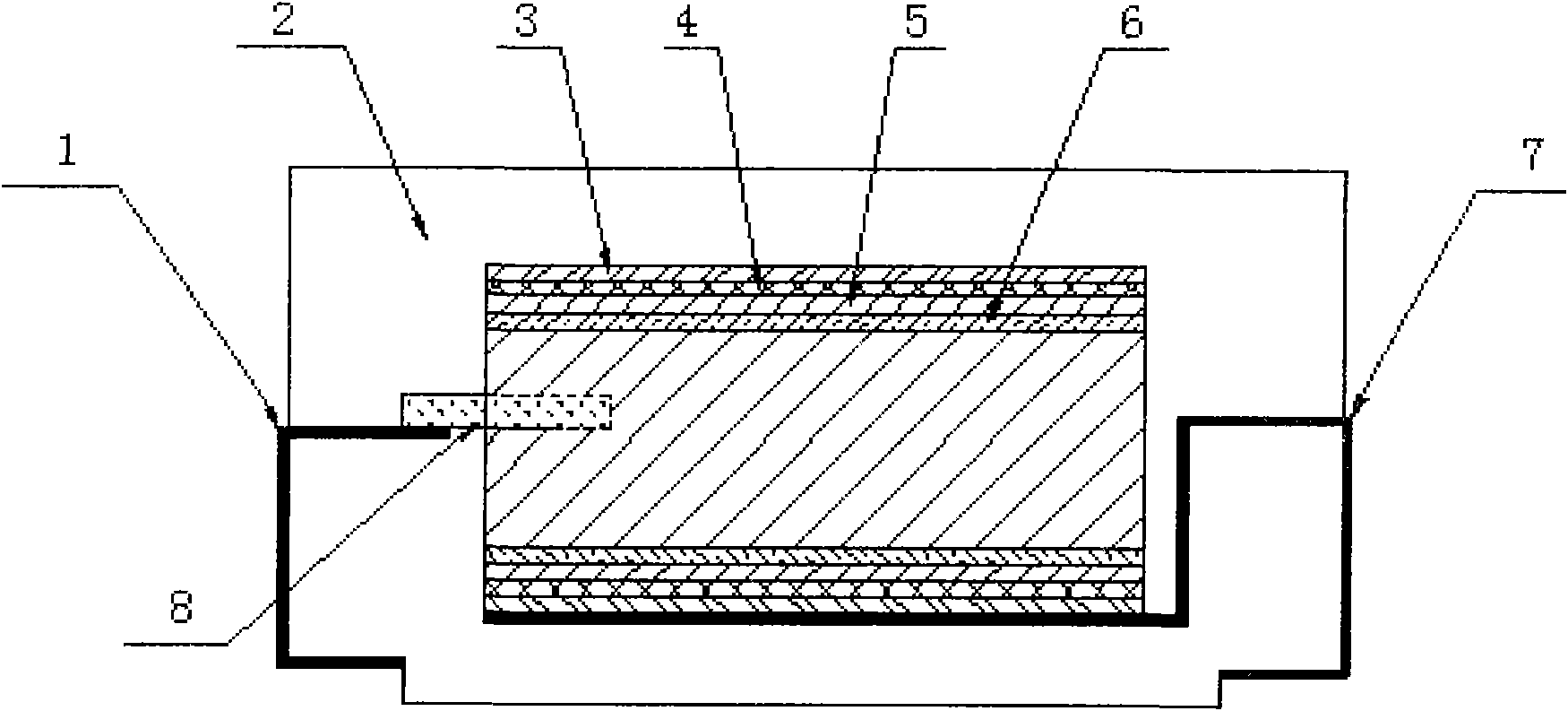

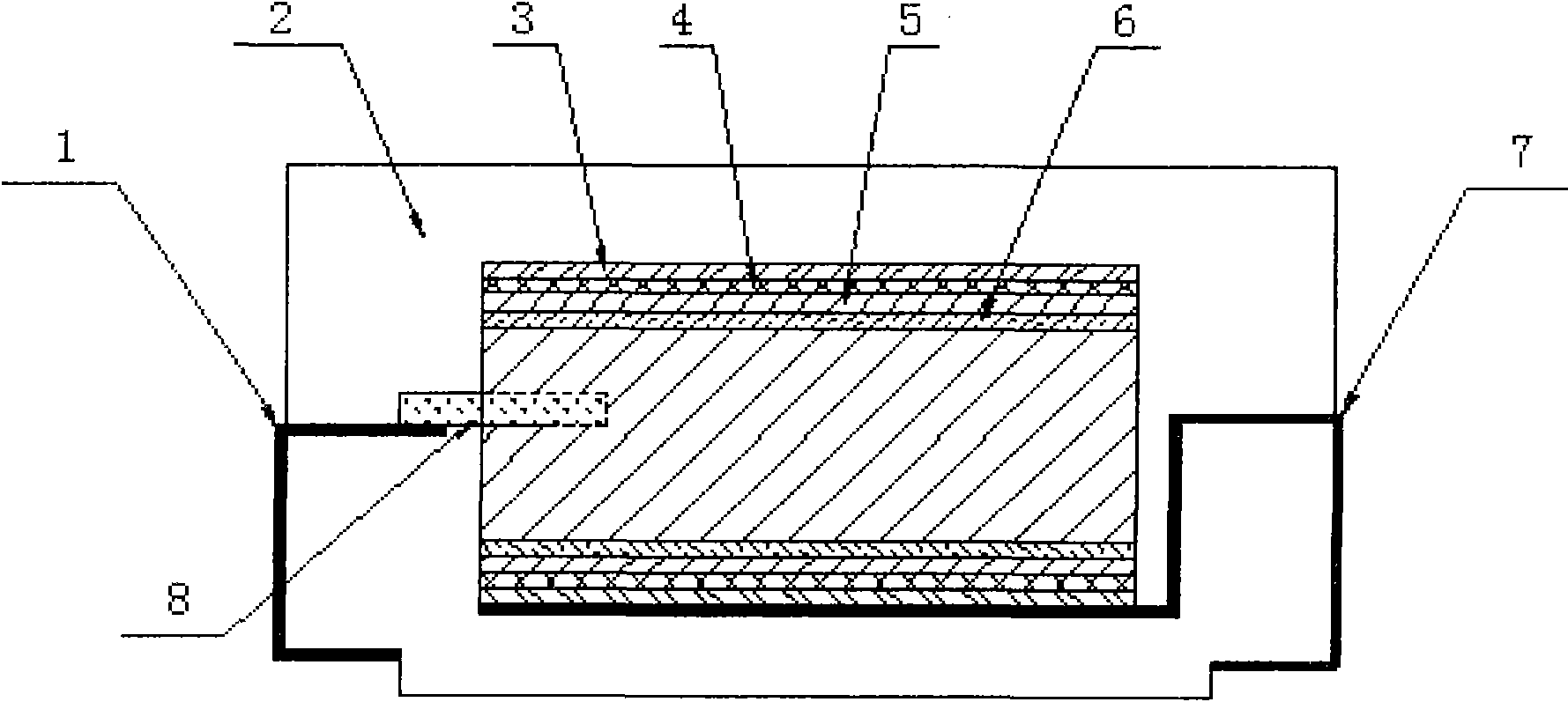

[0027] As shown in accompanying drawing 3 and accompanying drawing 4, a preparation method of a solid electrolyte niobium-tantalum composite capacitor is prepared by mixing niobium and tantalum to make a niobium-tantalum composite capacitor, using tantalum powder and niobium powder, or tantalum powder and pure monoxide The mixture of niobium mixed in a certain proportion is the anode material, and then it is prepared into an electrolytic capacitor. The preparation method includes the steps of mixing, molding, sintering, energizing, and coating of tantalum powder and niobium powder (or niobium monoxide); the specific preparation method is as follows:

[0028] 1. Mix tantalum powder and niobium powder or tantalum powder and pure niobium monoxide in a certain proportion, wherein the proportion of tantalum powder is controlled between 5% and 95%, and the rest is niobium powder or niobium monoxide powder;

[0029] 2. According to the total weight of tantalum powder and niobium powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com