Large-area liquid-cooled heat dissipation device

A heat-dissipating device, a large-area technology, applied in the fields of instruments, electrical digital data processing, electrical components, etc., can solve the problem of uneven heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

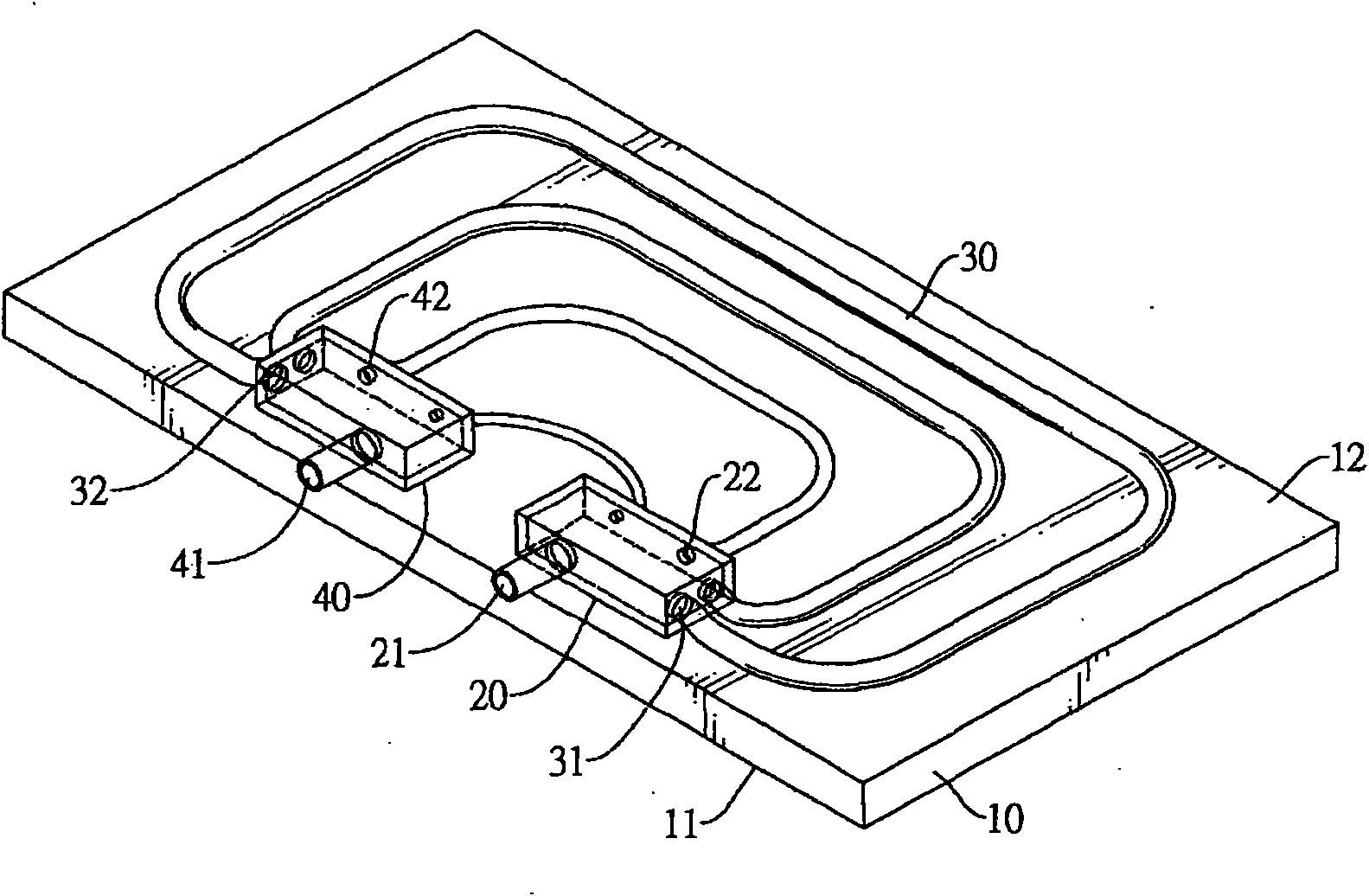

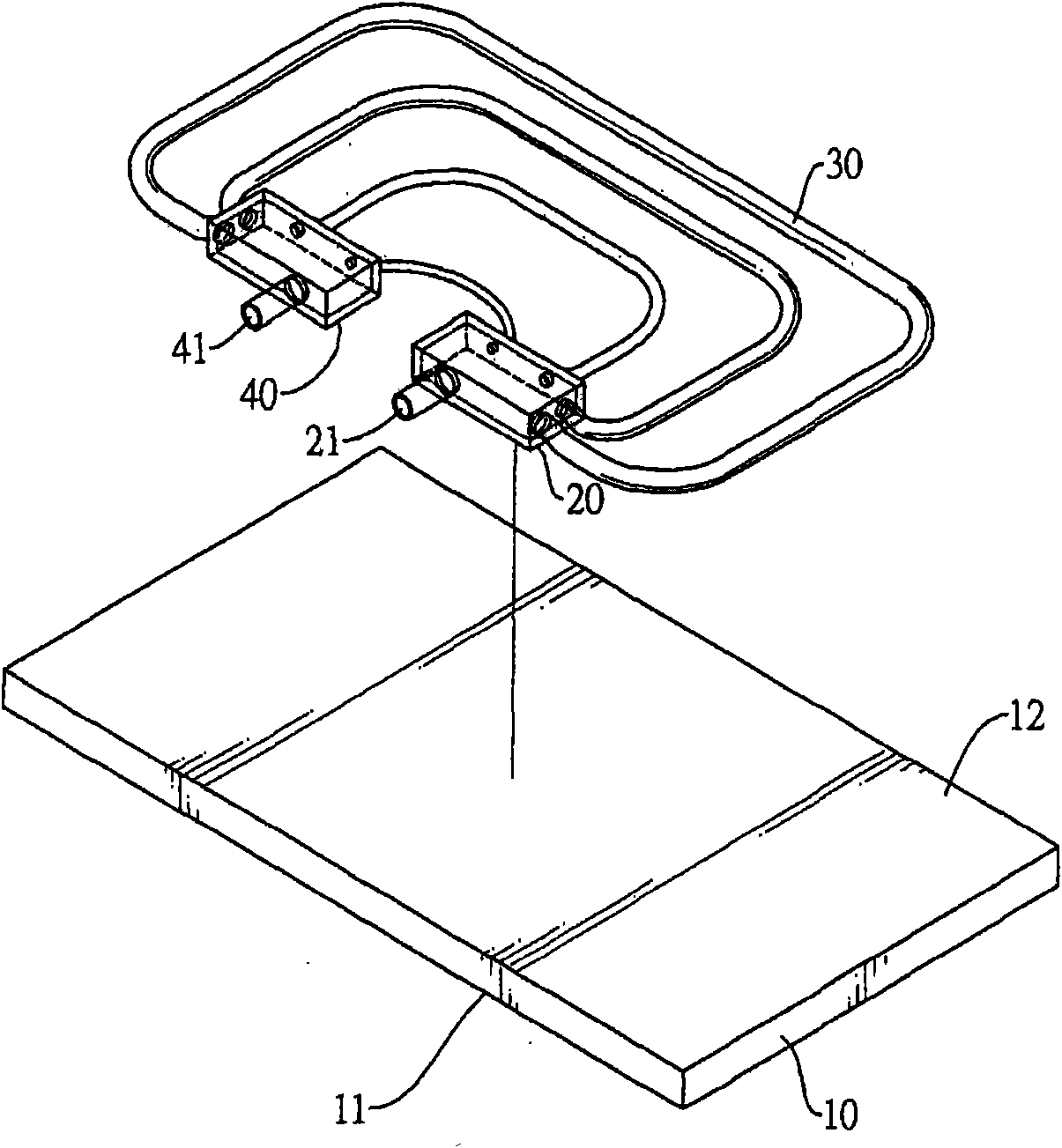

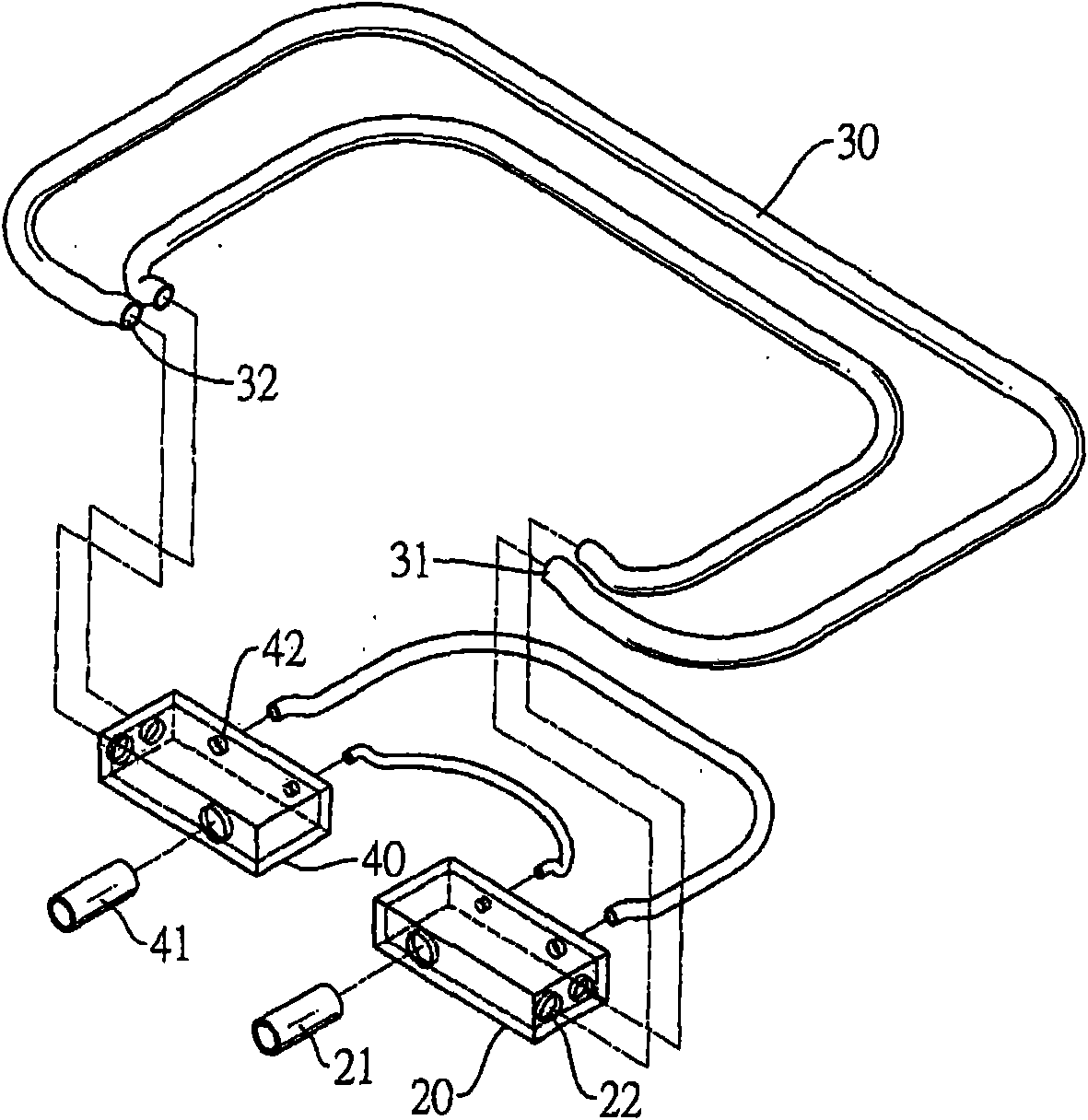

[0042] For the first embodiment of the present invention, please refer to Figure 1 to Figure 4 As shown, it includes a thermal diffusion plate 10 , a liquid injection distributor 20 , a plurality of heat absorption pipes 30 and a drain liquid collector 40 .

[0043] The above-mentioned thermal diffusion plate 10 has a heat-absorbing surface 11 and a heat-dissipating surface 12, wherein the heat-absorbing surface 11 is provided for forming thermal contact with a plurality of heat sources 50, such as electronic components on a server motherboard; in this embodiment, the The thermal diffusion plate 10 is a rectangular plate body.

[0044] see further Figure 4 As shown, the liquid injection distributor 20 has at least one water inlet 21 and a plurality of water delivery ports 22; in this embodiment, the liquid injection distributor 20 is welded on the heat dissipation surface 12 of the thermal diffusion plate 10, and adjacent One of the sides of the rectangular sheet heat diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com