Poly-lithium battery with high safety and high capacity and energy division process thereof

A high-safety, lithium-ion battery technology, applied in the manufacture of battery pack components, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve hidden dangers, thermal runaway safety of lithium-ion batteries, etc. Potential safety hazards, environmental performance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

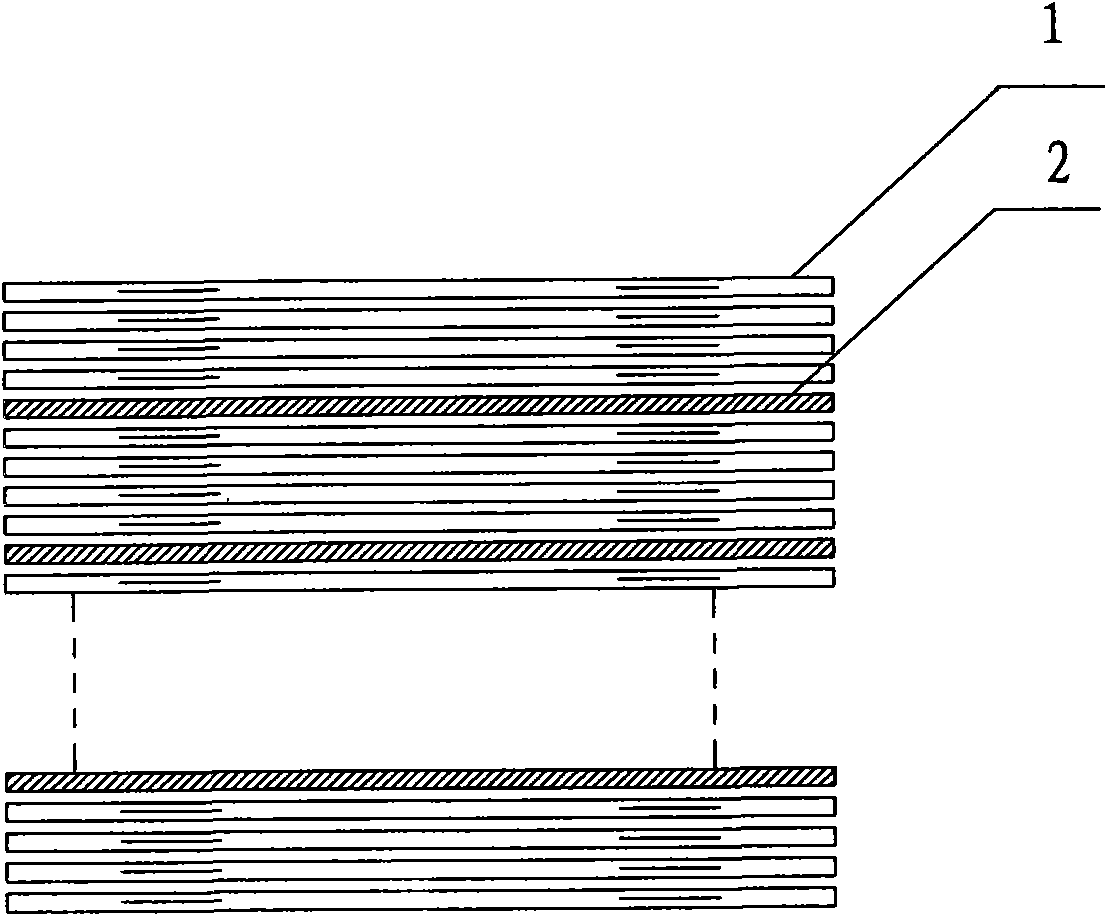

[0027] The present invention uses an energy splitting film 2 inside the polylithium battery to isolate a plurality of battery slices 1 into several energy units. The specific steps are described in detail in conjunction with the accompanying drawings.

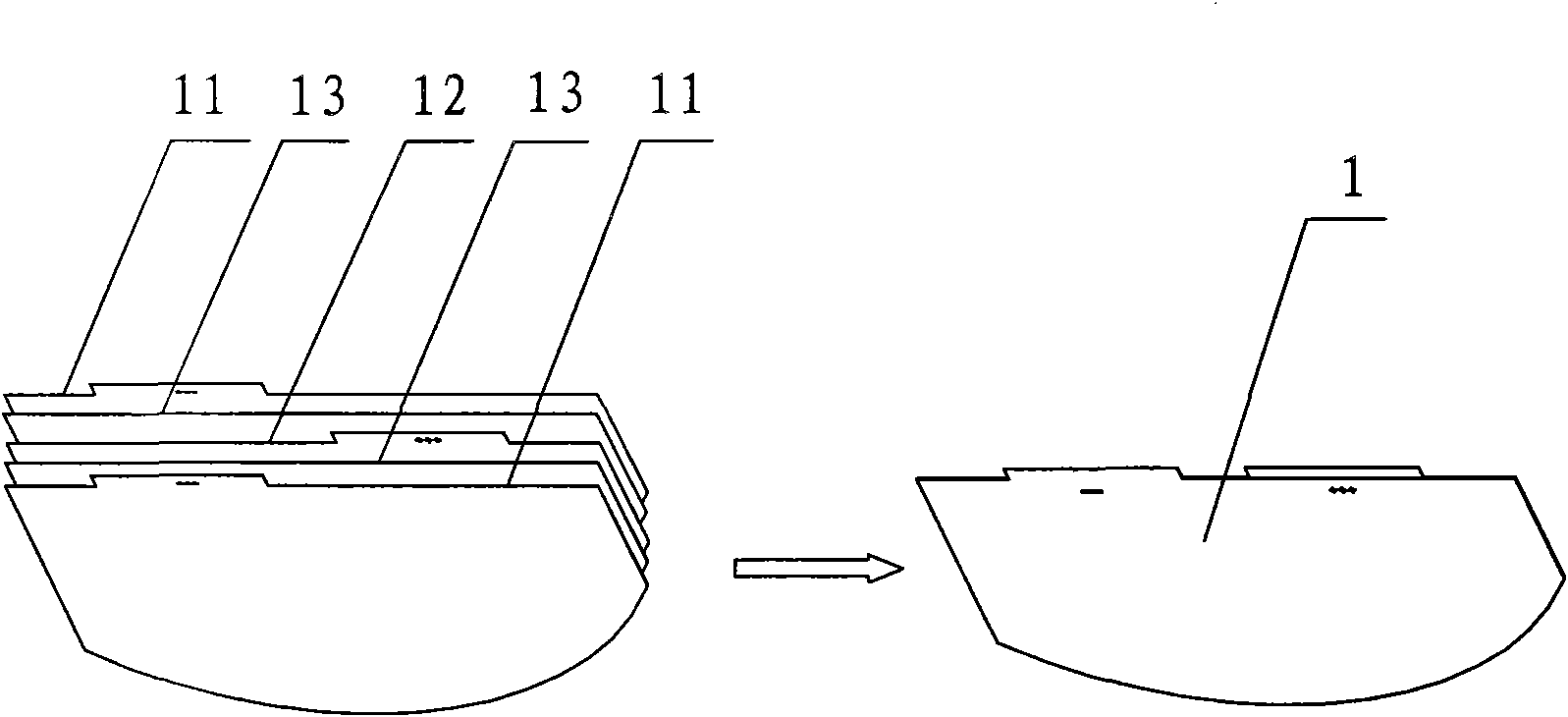

[0028] First, if figure 1 As shown, each battery sheet 1 of the polylithium battery in this embodiment adopts a laminated sheet structure of two negatives and one positive, that is, a positive electrode sheet 12 is sandwiched between two negative electrode sheets 11, and a positive electrode sheet 12 is used between the positive and negative electrode sheets. Porous ceramic diaphragm 13 separated. After being stacked, the battery sheet 1 is formed by thermal polymerization and solidification in a high-temperature electrolyte.

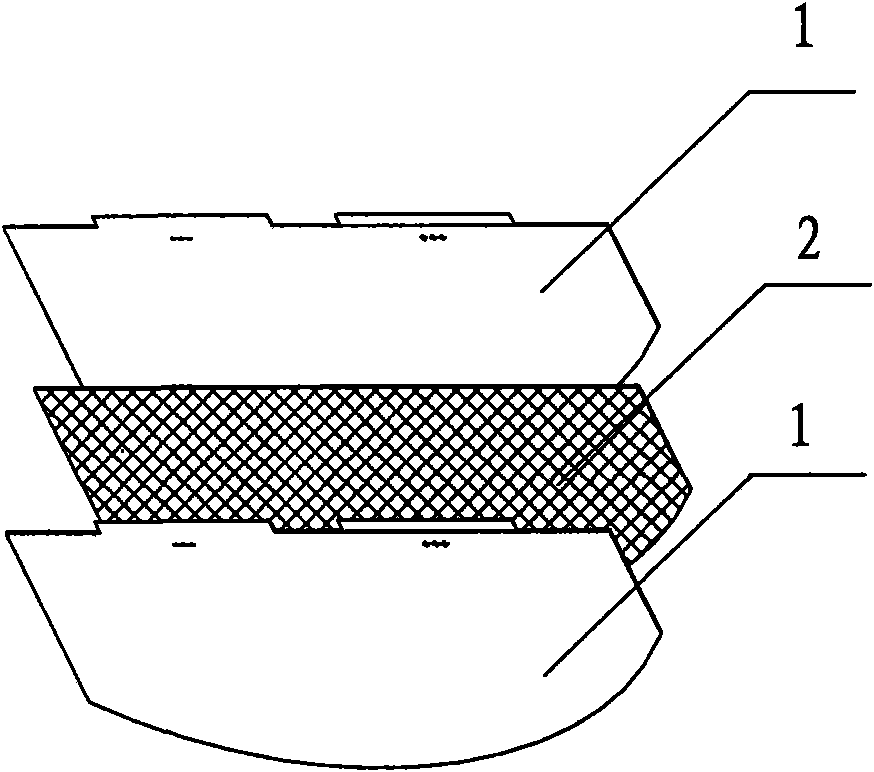

[0029] then see figure 2 , image 3 , with four battery slices 1 as an energy unit, separated by an energy splitting membrane 2 . The shape of the energy splitting membrane 2 is generally the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com