Rapid investment casting method of complex thin-wall component

A technology of thin-walled parts and investment casting, which is applied to casting molding equipment, molds, mold components, etc., can solve the problems of long production cycle, complicated materials, environmental pollution, etc., shorten the production cycle, and omit the dewaxing process. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the drawings and embodiments.

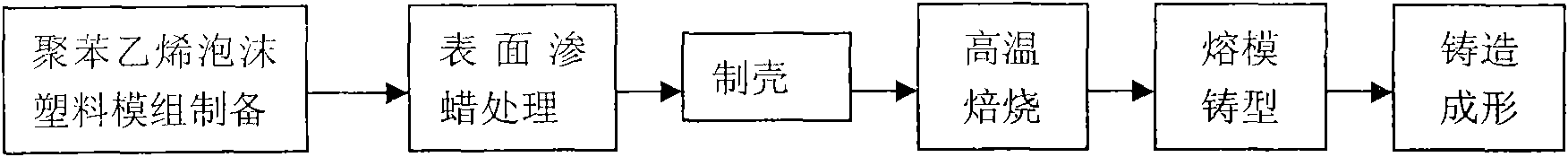

[0027] Such as figure 1 As shown, the process of the present invention is: use polystyrene rapid prototyping technology to produce thin-walled polystyrene foam investment casting patterns and pouring systems of complex shapes, and improve the surface quality of the casting patterns through the surface low-temperature wax infiltration process, and then After surface treatment, the foamed plastic module is slurried for multiple times to make the melted model shell, roasted at high temperature to completely gasify the foamed plastic, and finally cast metal to obtain a precision casting.

[0028] The embodiment is a complex curved thin-walled sandwich part of the head of a high-speed train.

[0029] Reference figure 2 with image 3 The complex curved thin-walled sandwich structure of the head of the high-speed train shown, because the part has a complex curved structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com