Driving mechanism and slip flask mold molding device in mold molding equipment

A driving mechanism, a technology of unboxing casting, which is applied in casting and molding equipment, molding machines, and equipment for loosening models, etc., can solve the problem of high initial cost of hydraulic units and hydraulic valves, time required for assembly or maintenance, and system and valve structure. Complicated and other problems, to achieve the effect of easy maintenance, easy handling, and reducing the cost of component replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

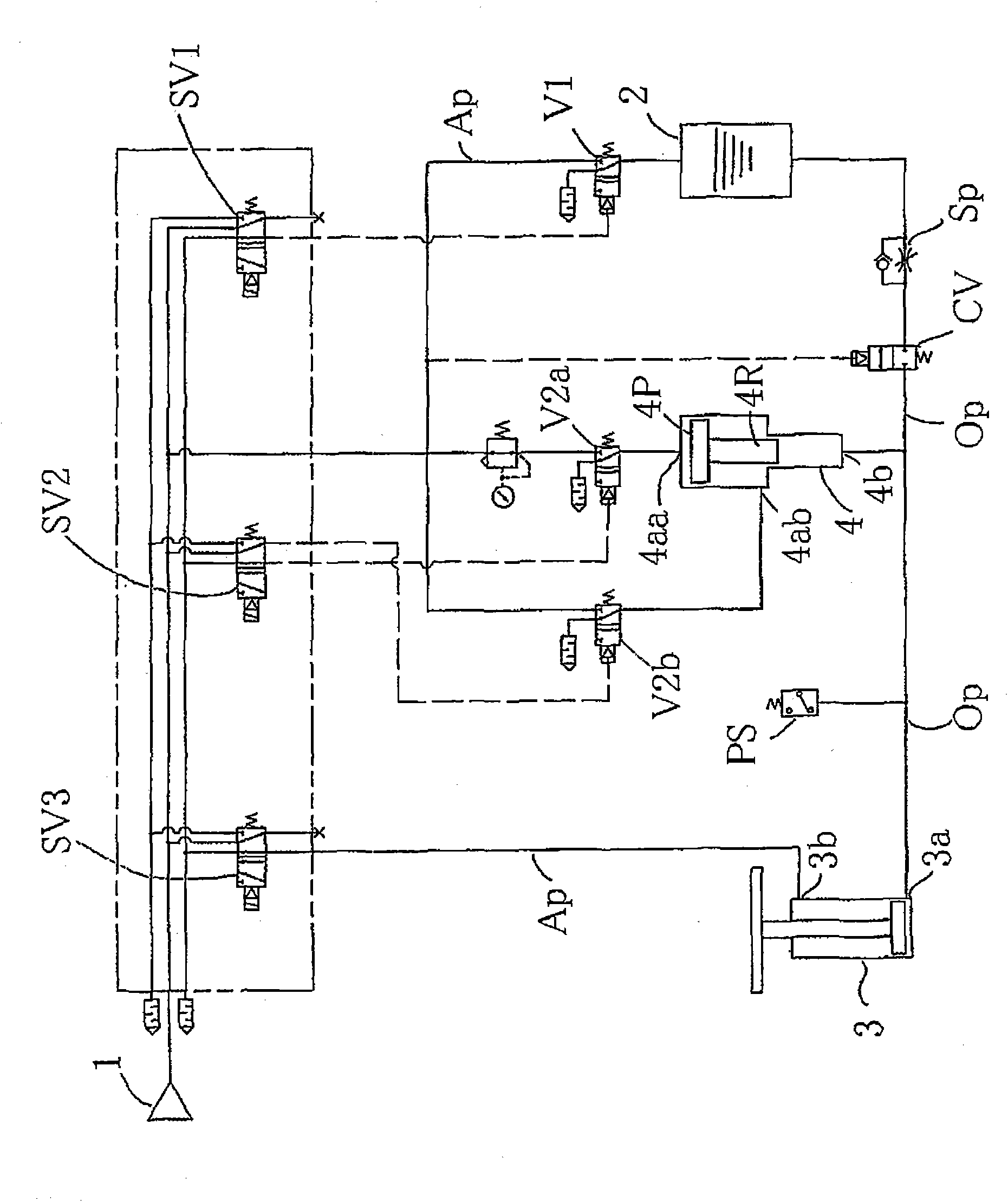

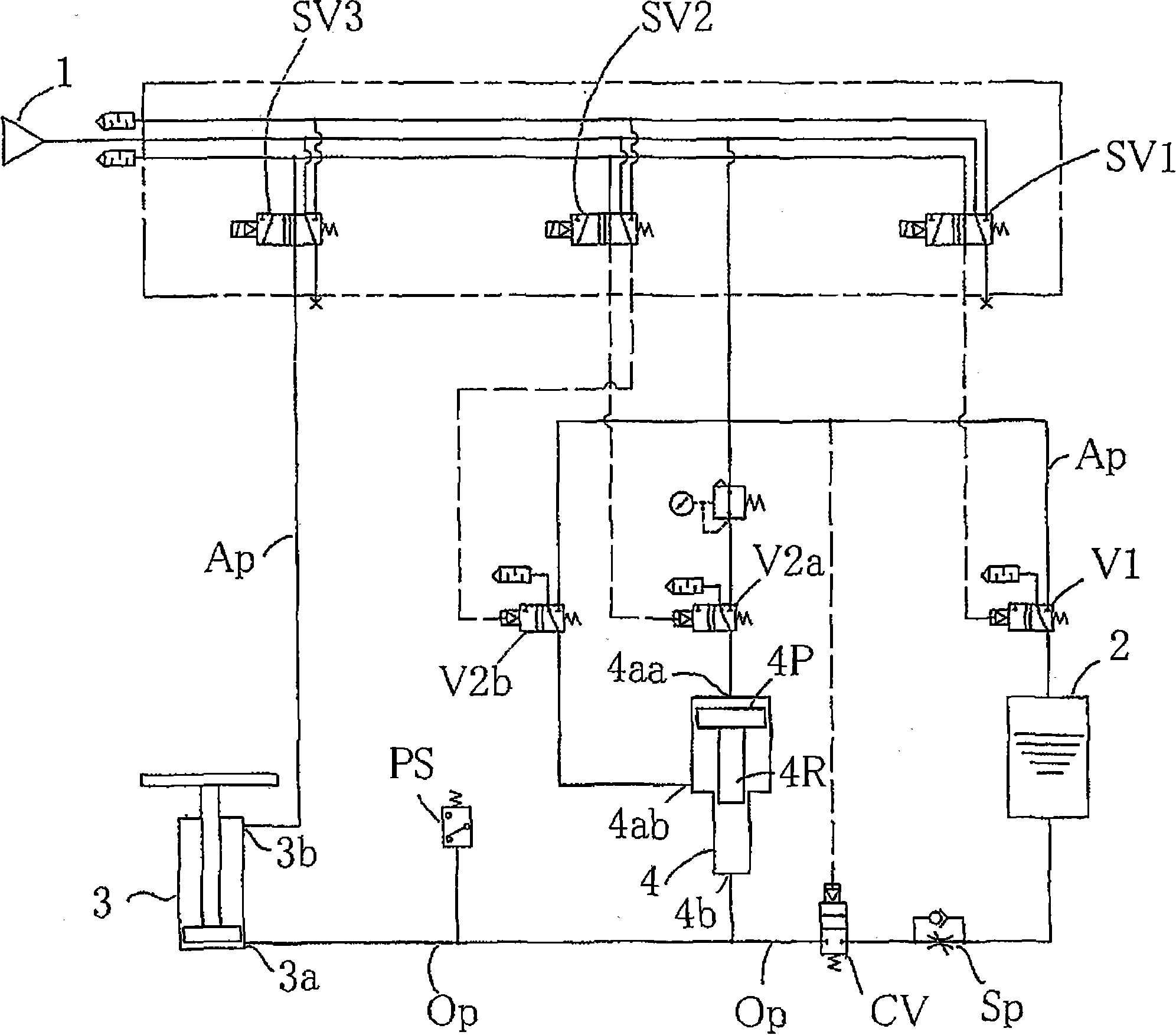

[0044] exist figure 1 Among them, the compressed air source 1 is a source that takes in compressed air or generates compressed air. One end of the upper portion of the oil tank 2 is connected to the compressed air source 1 in a communicable and disconnectable manner through an air pipe Ap. In order to enable communication and disconnection, a solenoid valve SV1 and a valve V1 operable by the solenoid valve SV1 are used. Furthermore, the lower part of the oil tank 2 is connected to the hole 3a (going hole) of the frame mounting squeeze cylinder 3 so that communication and disconnection are possible via hydraulic piping. Furthermore, the other hole 3b (return hole) of the frame housing squeeze cylinder 3 is connected to the compressed air source 1 in a communicable and disconnectable manner via the air pipe Ap.

[0045] Furthermore, the hole 4aa (going hole) and the hole 4ab (return hole) of the booster cylinder 4 are connected to the compressed air source 1 so that communicat...

Embodiment 2

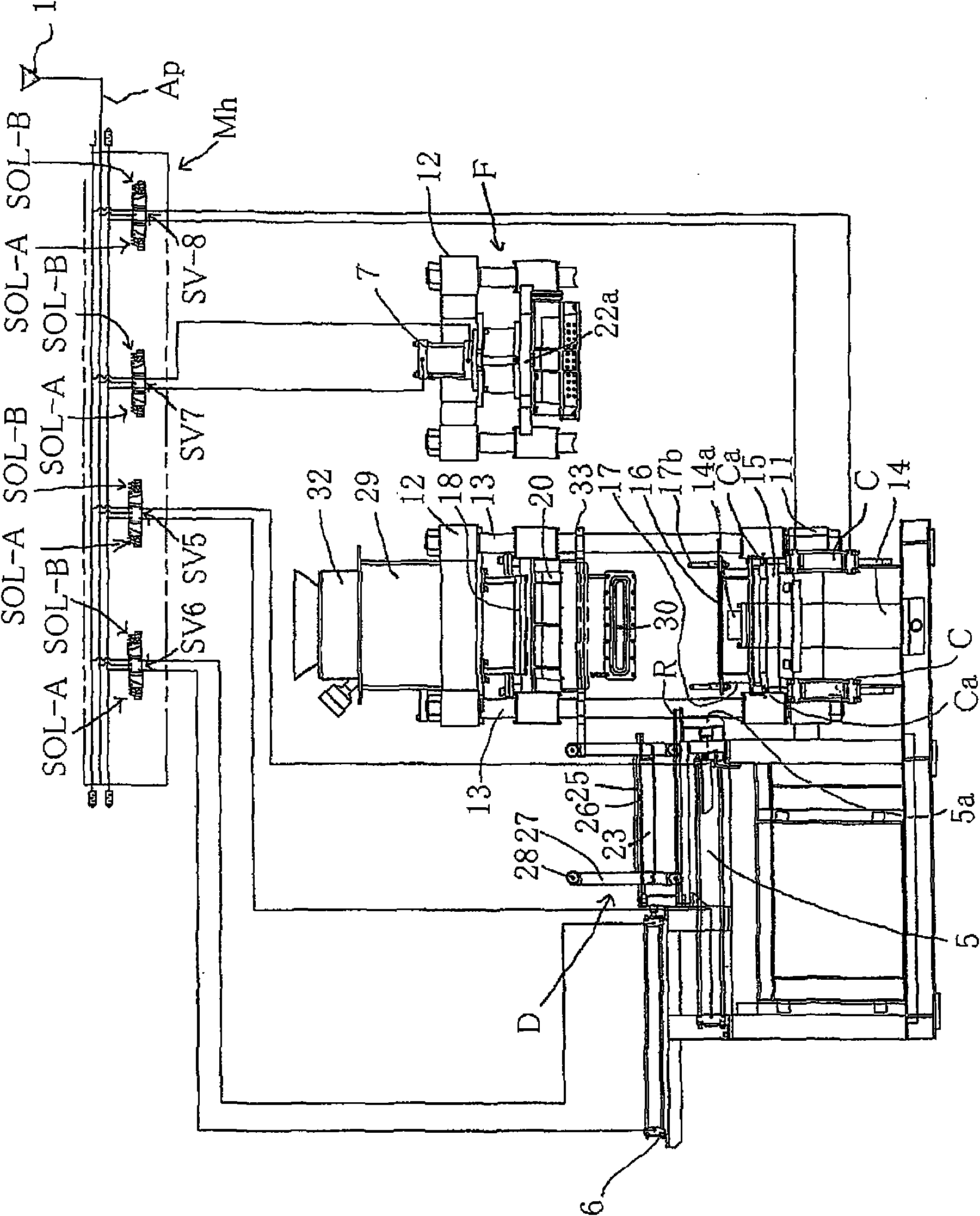

[0055] figure 2 It is a partial schematic piping system diagram of the drive mechanism of the present invention and a side view (including a partial front view) of the out-of-box mold molding device. In addition, in the driving mechanism, only a part of the air pressure piping is shown. exist figure 2 Among them, in the driving mechanism, the part of the driving frame where the extrusion cylinder 3 is placed can be the same as the embodiment 1, so this part is omitted. exist figure 2 Among them, the drive mechanism of the out-of-box mold molding device (hereinafter simply referred to as the out-of-box mold molding device) as sand molding equipment has a compressed air source 1 . Solenoid valves SV5 to SV8 utilizing air pressure are integrally connected with a compressed air source 1 via a manifold Mh. Furthermore, the compressed air source 1 and the mold ejection cylinder 5 are connected so as to be able to communicate and cut off via the solenoid valve SV5. Furthermor...

Embodiment 3

[0066] figure 2 It is a partial schematic piping system diagram of the drive mechanism of the present invention and a side view (including a partial front view) of the out-of-box mold molding device. In addition, only a part of the air pressure piping is shown. exist figure 2 In , the driving mechanism for driving the frame to place the extrusion cylinder 3 is the same as that in Embodiment 1, so this part is omitted.

[0067] exist figure 2 Among them, the door-shaped frame F is integrally connected with four-corner pillars 13 and 13 connecting the lower base frame 11 and the upper frame 12 . Frame placement extrusion cylinder 14 is installed on the upper surface central part of lower base frame 11 in the mode facing upwards, and lower pressing plate 16 is installed on the front end of the piston rod 14a of frame placement extrusion cylinder 14 through lower extrusion frame 15 . In addition, sliding bushes of at least 10 mm or more are provided at the four corners of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com