Abrasive fiber polishing disk, polishing machine with same and polishing method using same

A polishing disc and polishing machine technology, which is applied in the field of silicon wafer manufacturing, can solve the problems of separation of abrasive fiber metal discs, limitation of polishing precision, waste of resources, etc., and achieves the effect of simplifying the process, improving the polishing precision, and improving the polishing mirror effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

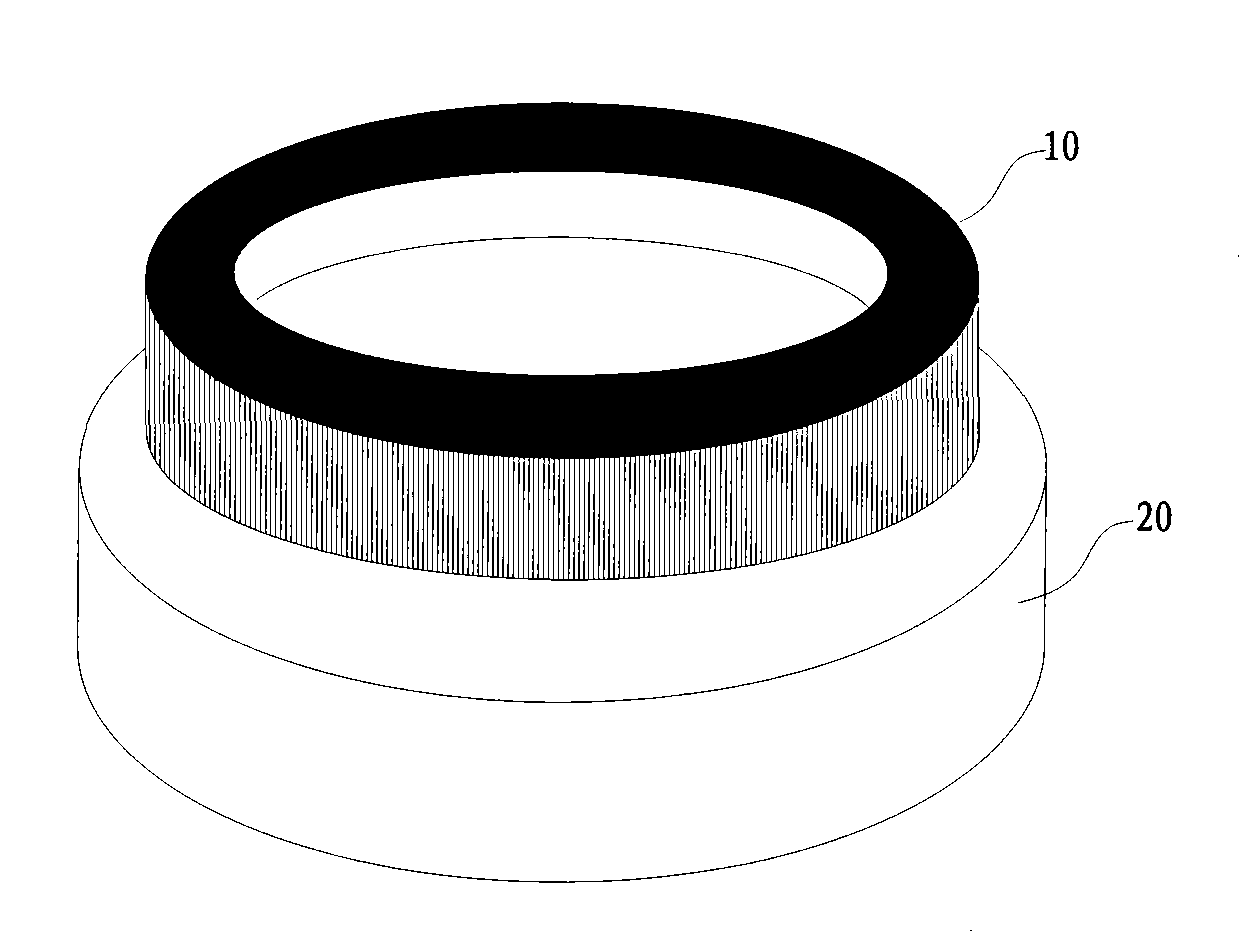

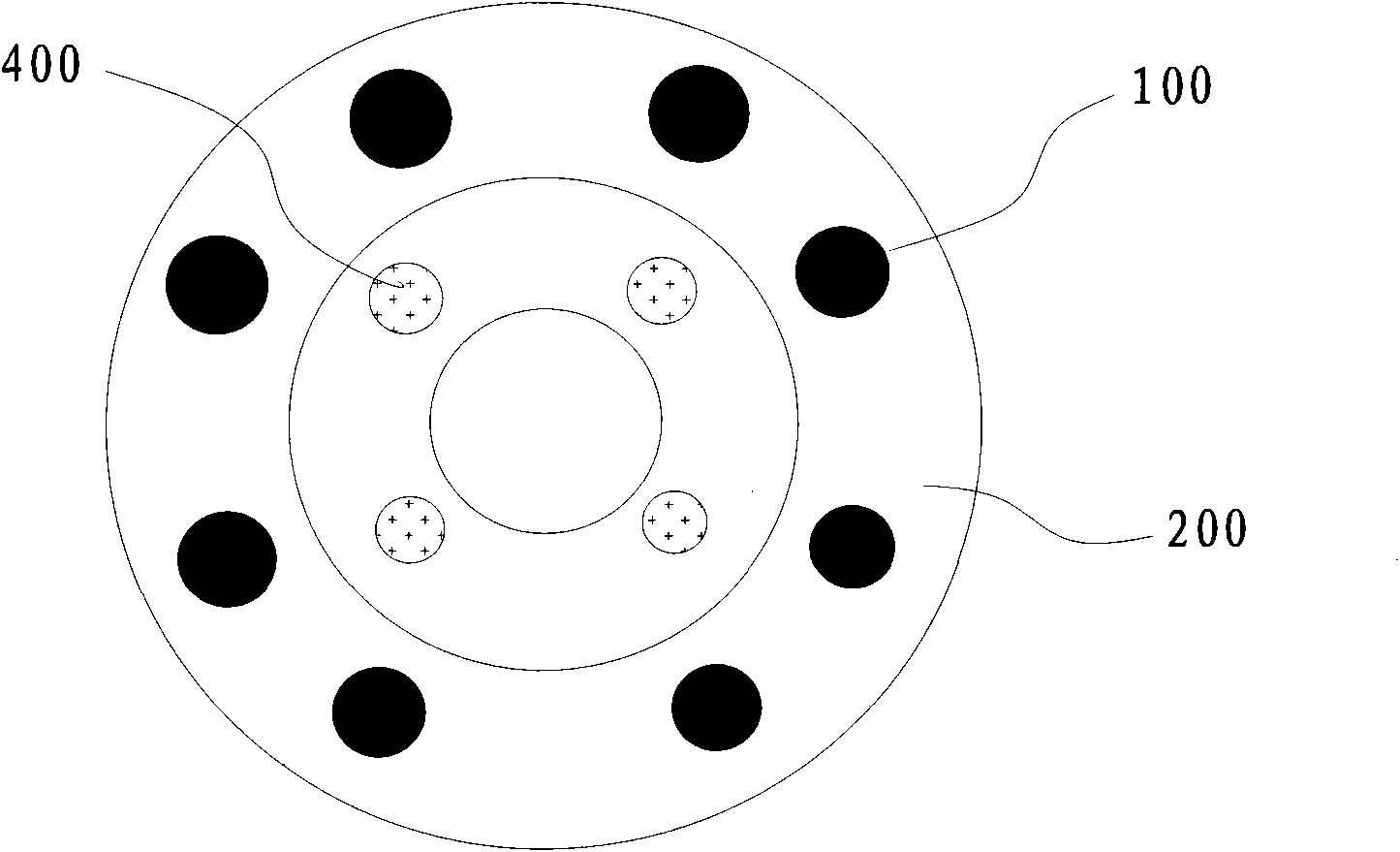

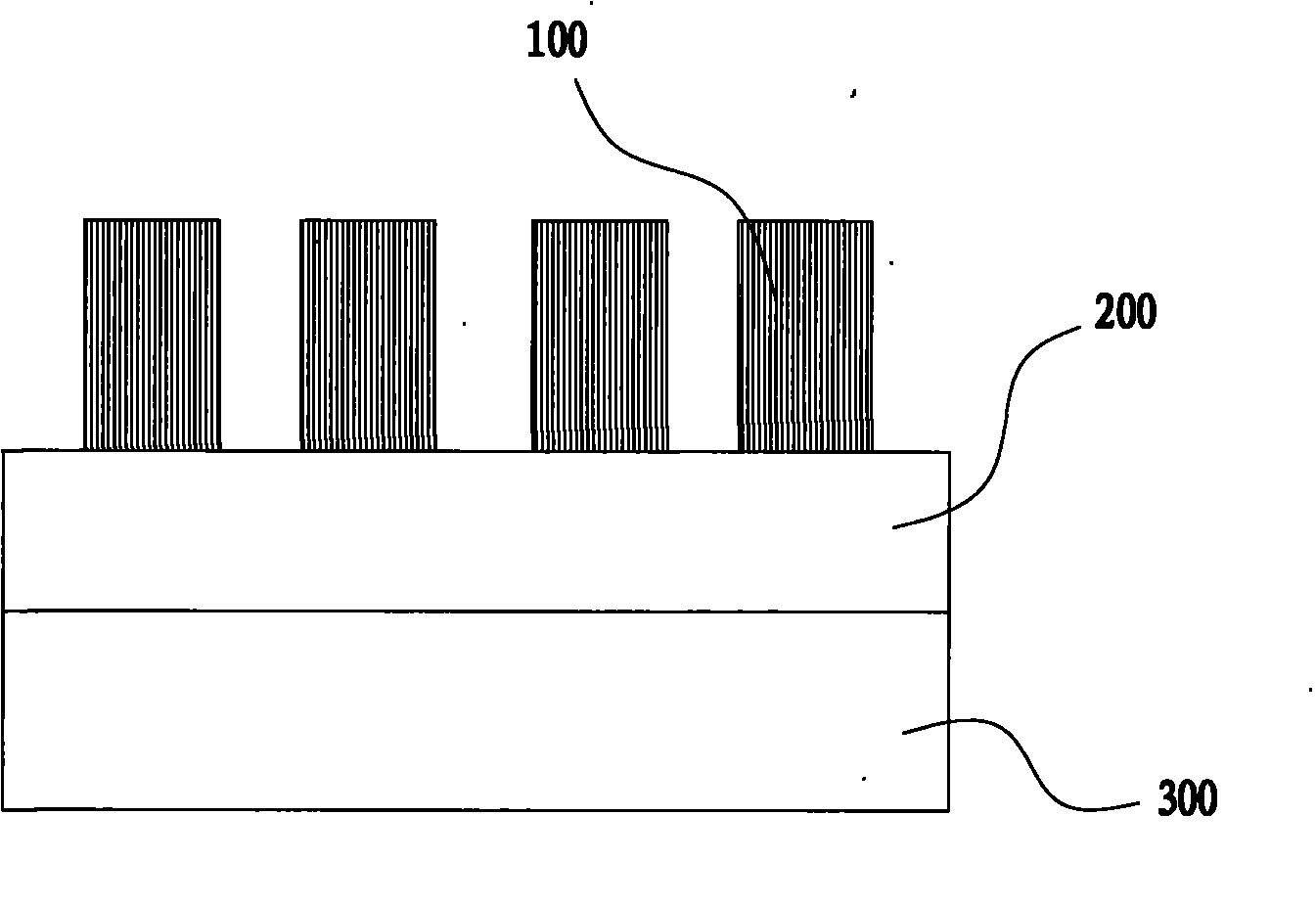

[0037] The present invention mainly proposes an abrasive fiber polishing disc, by fixing the abrasive fiber bundles formed by a plurality of abrasive fiber bundles in a plurality of holes arranged at intervals in the circumferential direction of the upper mounting disc, and making the upper mounting disc The disc is detachably installed on the lower mounting disc, and the impurities, shed diamond particles and grinding debris generated during the polishing process can be removed from the surface of the silicon ingot in time, thereby furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com