Process for treating oil field water

A technology for treating process and oilfield water, which is applied in the field of comprehensive recovery and utilization treatment process, can solve the problems of ignoring the comprehensive recovery and utilization of resources, and achieve the effect of alleviating the tension of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

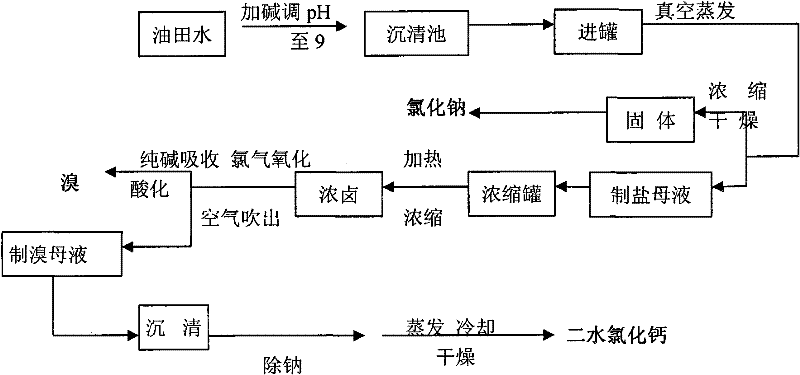

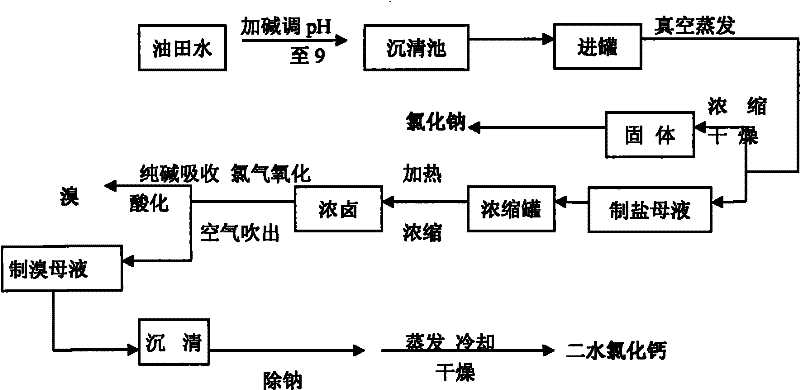

[0018] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0019] A kind of oil field water treatment process, take following process step:

[0020] (1), the oilfield water passes through the sedimentation tank, adds alkali to adjust the pH=9, and then settles;

[0021] (2), the supernatant liquid prepared by step (1) is passed into a three-effect evaporating tank for vacuum evaporation, and the sodium chloride crystals crystallized out in the evaporating tank are centrifuged and dried to obtain solid sodium chloride;

[0022] (3) Heat and concentrate the salt-making mother liquor in the previous step. When the concentration of the salt-making mother liquor is 8 to 9 times, the salt-making mother liquor is discharged into the concentrated brine tank, and heated by secondary steam to increase the salt-making mother liquor by 4 to 6 times. Baumé degree, this time is concentrated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com