Treatment process for oilfield water comprehensive recovery

A treatment process, oilfield water technology, applied in the field of comprehensive recycling treatment process, can solve the problems of neglecting the comprehensive recycling of resources, etc., and achieve the effect of alleviating the tension of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

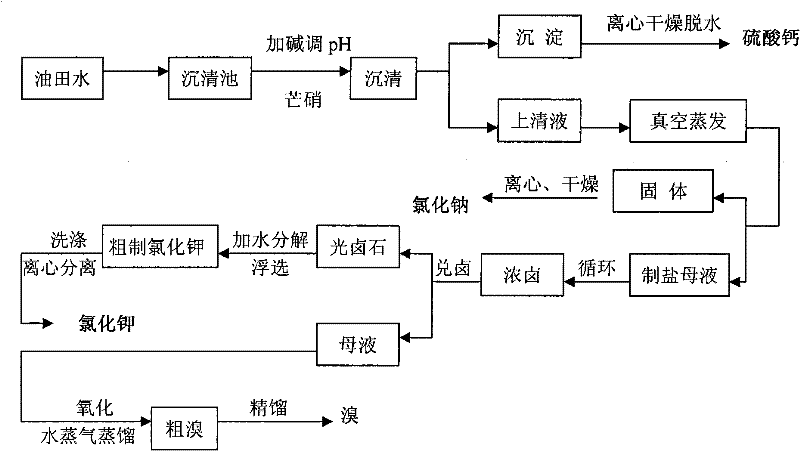

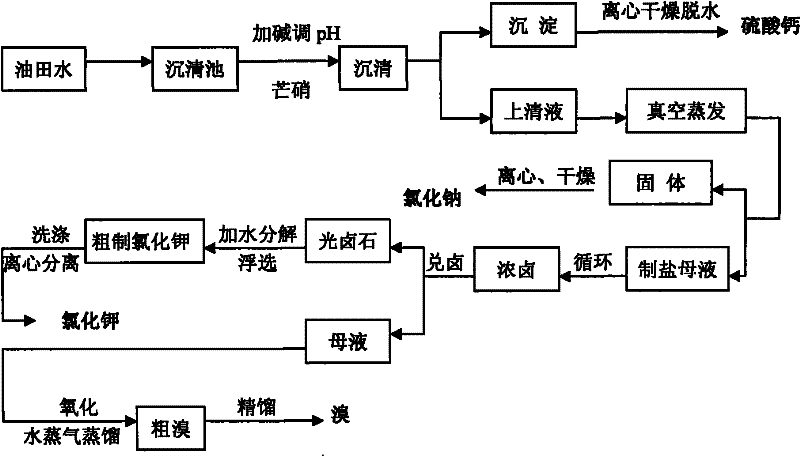

[0021] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0022] A treatment process for comprehensive recovery and utilization of oilfield water, which takes the following process steps:

[0023] (1), the oil field water passes through the sedimentation pond, and in the pond, add 120% of the theoretical amount of thenardite needed for calcium sulfate with the calcium ions in the oilfield water, stir evenly, and add sodium hydroxide to adjust pH=about 10 simultaneously, Shen Qing;

[0024] (2), the precipitate prepared in step (1) is produced calcium sulfate by centrifugal drying and dehydration;

[0025] (3), the supernatant liquid prepared by step (1) is passed into a three-effect evaporating tank for vacuum evaporation, and the sodium chloride crystals crystallized out in the evaporating tank are centrifuged and dried to obtain solid sodium chloride;

[0026] (4), the salt-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com