Method for preparing ink holdout type metallized paper

A technology of aluminized paper and vacuum aluminized paper, used in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of poor alkali resistance, secondary pollution of beer bottles, polluted cleaning liquid, etc., and achieves easy cleaning of beer bottles, Improve the environmental protection level and reduce the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

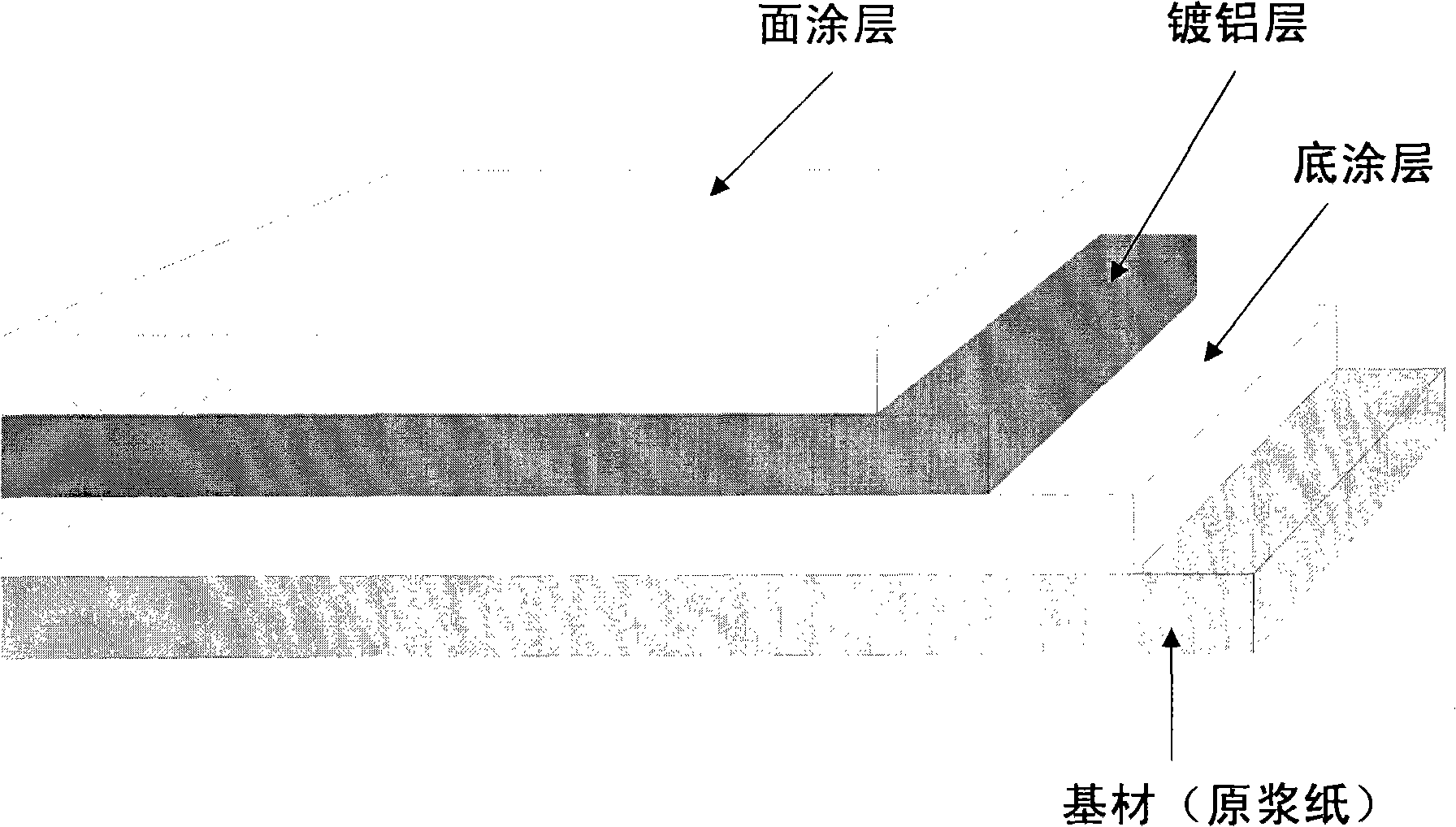

[0030] The invention belongs to a functional paper, in particular to a method for preparing an aluminized paper with ink-carrying function, which is used for label printing and the like.

[0031] In the present invention, on the basis that other production processes and technologies of vacuum aluminum-coated paper remain unchanged, it is specifically related to a kind of innovation (hereinafter referred to as an ink-supporting coating) for primer and topcoat in the production of vacuum metal-coated paper Coatings, both include primer and topcoat).

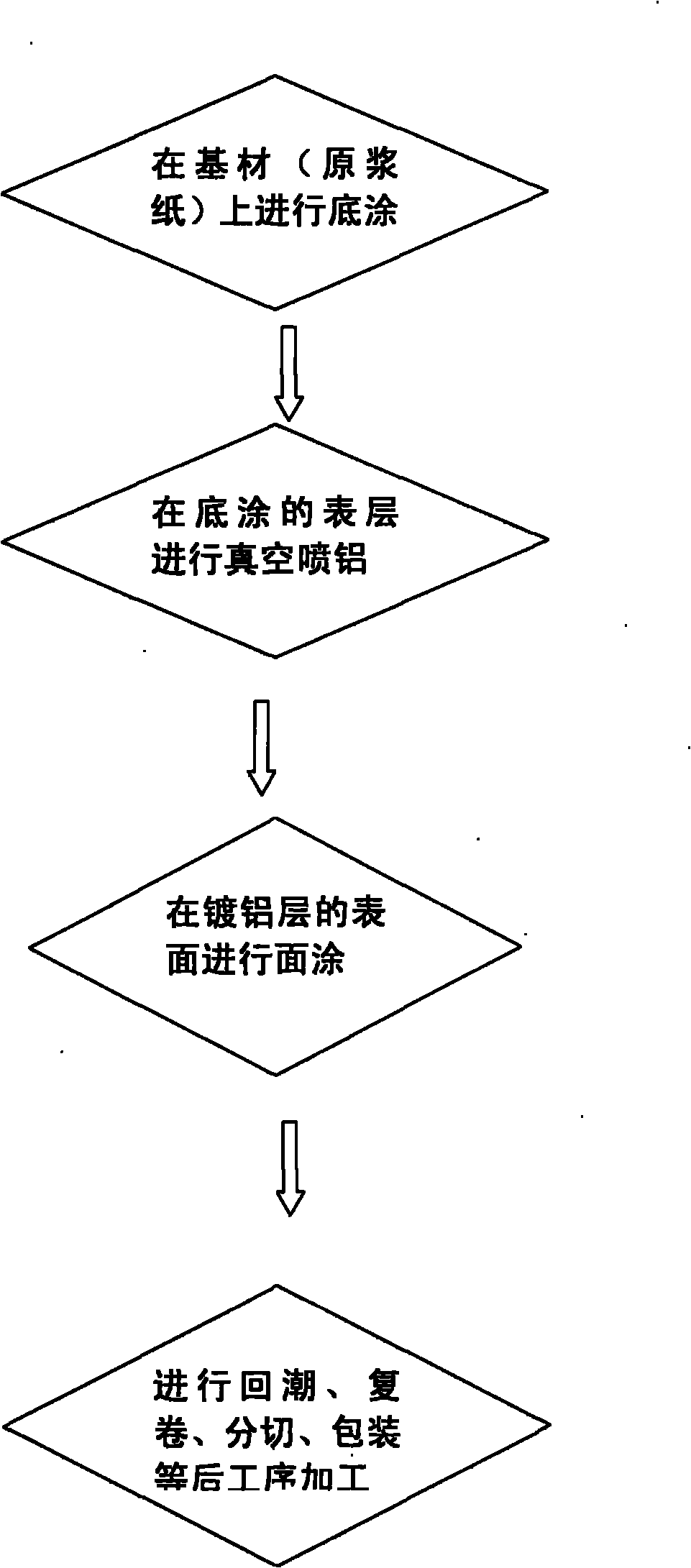

[0032] The specific innovation and implementation steps include:

[0033] 1. Prime the glossy surface of the original pulp paper (substrate) with ink-carrying paint on the coating machine. In this step, except for ink-based coating innovation, other links are the same as conventional vacuum aluminum-coated paper production.

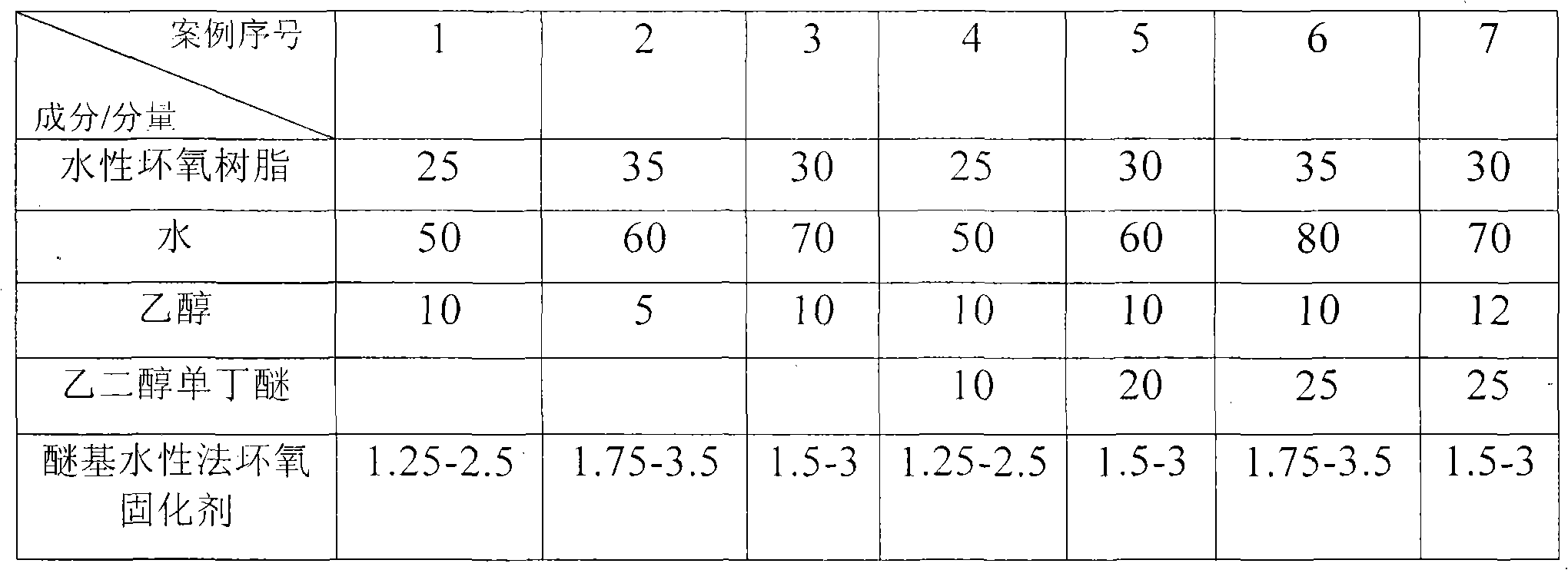

[0034] The ink-supporting type primer that the present invention relates to is mainly characterized in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com