Heat exchange plate used for plate type heat exchanger

A plate heat exchanger, heat exchange plate technology, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problem of large flow resistance and pressure loss, difficult to use heat exchange process requirements, heat exchange plate structure complex problems, to achieve the effect of small pressure loss, convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

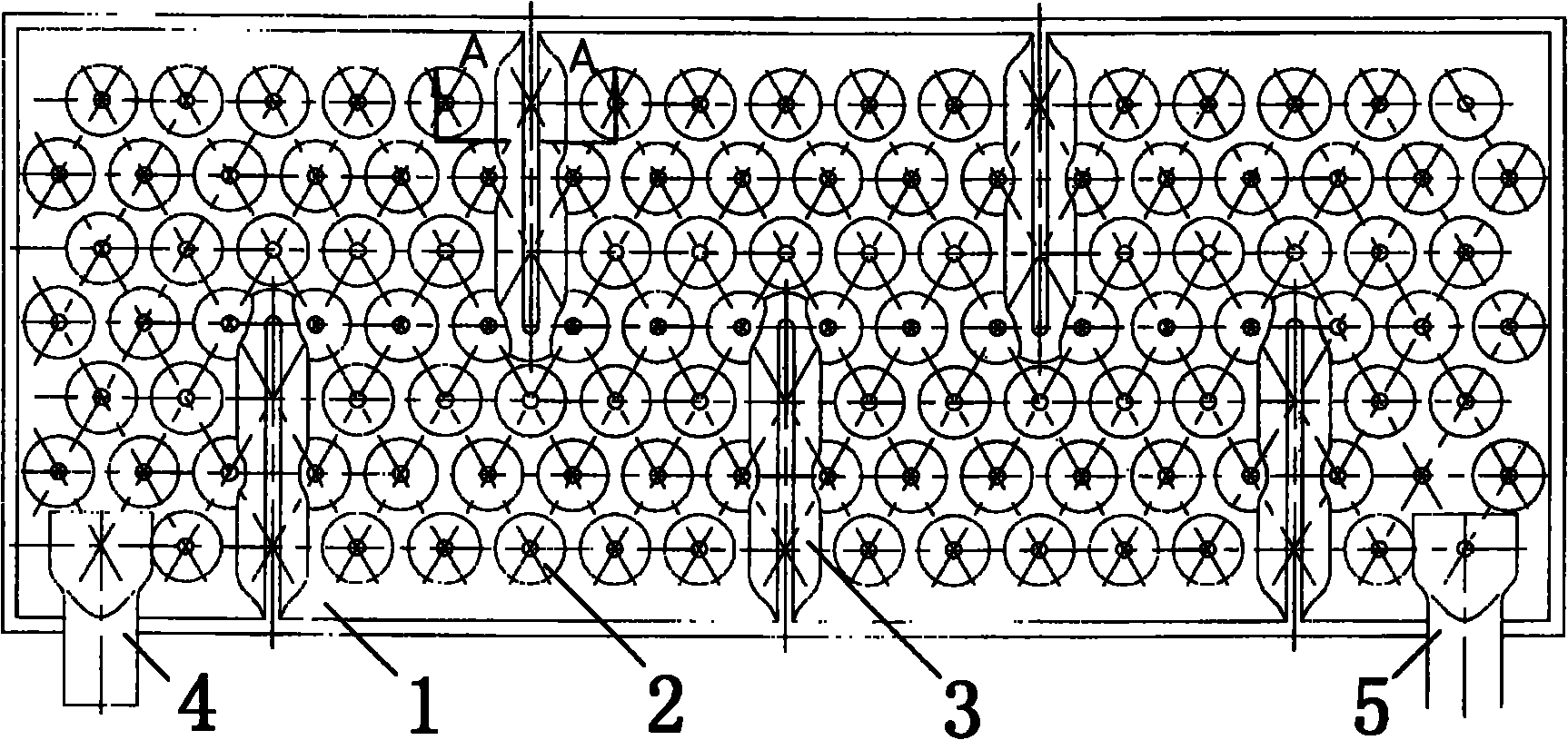

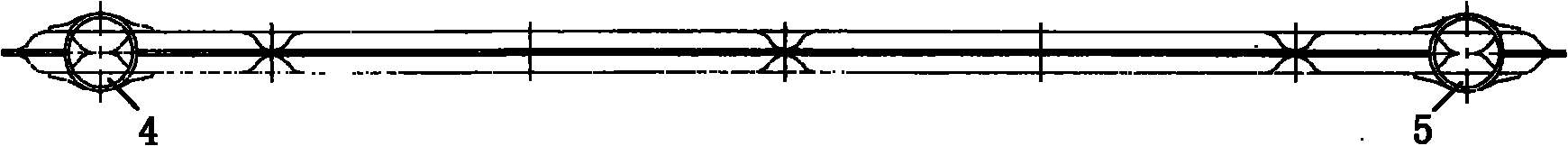

[0018] When in use, the two boards 1 are used in combination: the two boards 1 face each other, weld or seal the baffle at the edge, and set the inlet 4 and the outlet 5, and connect the opposite pits 2 planes by spot welding, then Flow channels are formed in the closed space between them, and media with different calorific values flow inside and outside the flow channels to exchange heat.

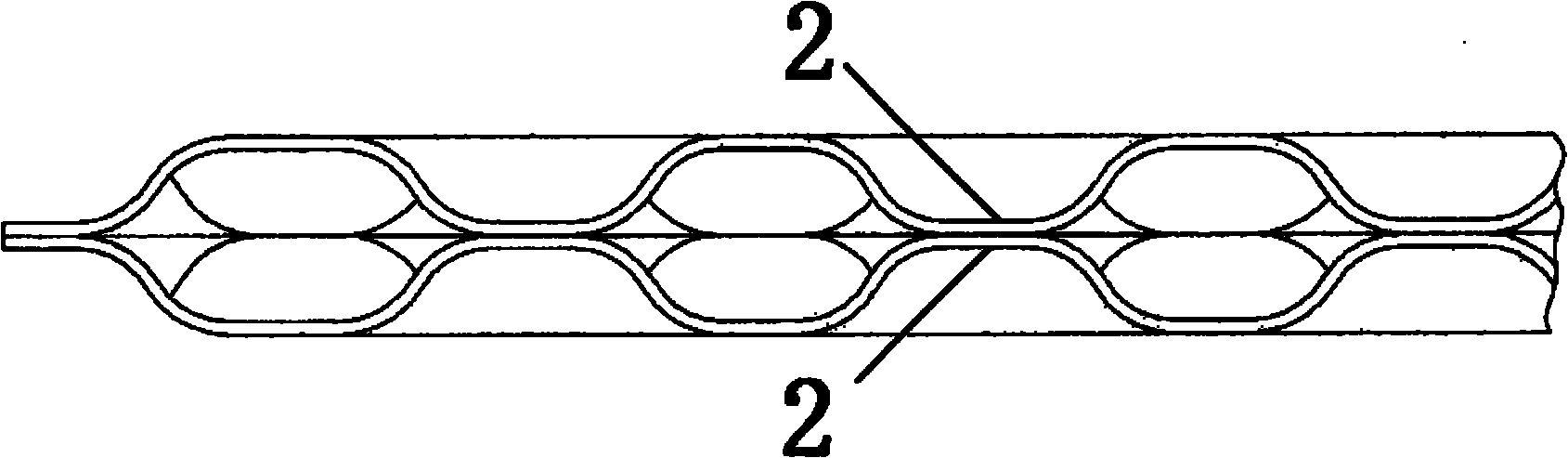

[0019] The entire surface area of the pits 2 and the recessed grooves 3 in the flow channel plays the role of heat exchange, thus greatly enhancing the heat exchange intensity and heat exchange efficiency. Moreover, the fluid inside the channel can achieve highly turbulent flow.

[0020] The thickness of the plate body 1 and the pit 2 can be designed and manufactured according to the pressure of the applicable environment.

[0021] The purpose of the recessed groove 3 is to enable the medium in the flow channel to flow through all effective heat exchange areas and form a flow channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com