Mercury concentration on-line detection method in smoke gas

A detection method and technology of mercury concentration, which is applied in the direction of measuring devices, preparation of test samples, instruments, etc., can solve problems such as inability to analyze large-flow coal-fired flue gas, complicated detection process, and inability to realize online detection of mercury concentration, etc., to achieve Elimination of problems related to gold wire enrichment and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, a bypass pipeline is set up in the coal-fired flue gas pipeline in the Dushi coal mining area of Sichuan, and the gas flow controller is used to control the sampling gas flow rate in the bypass pipeline, and the coal-fired smoke in the Dushi coal mining area of Sichuan is tested online by the method of the present invention. The mercury concentration in the air, the specific test steps are as follows:

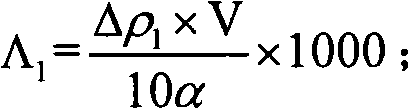

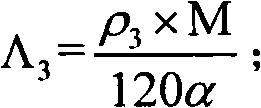

[0029] (1) On-line sampling from the flue gas pipe through the bypass pipe, control the sampled flue gas to flow into the 20L water treatment solution in the graduated container at a flow rate of 20L / min, perform reaction and dust removal treatment, and start timing at the same time, at this time is 0; the water treatment solution in the scale container is a solution in which 1mol / L sodium acetate solution is added to deionized water to adjust the pH value to 3.8-4.2. Then, the flue gas after the water treatment solution reaction and dust removal ...

Embodiment 2

[0042] In this embodiment, a bypass pipeline is set up in the coal-fired flue gas pipeline of the Songzao Mine in Qijiang, Chongqing, and the sampling gas flow rate in the bypass pipeline is controlled by a gas flow controller, and the coal-fired smoke of the Songzao Mine in Qijiang, Chongqing is tested online by the method of the present invention. The mercury concentration in the air, the specific test steps are as follows:

[0043] (1) On-line sampling from the flue gas pipeline through the bypass pipe, control the sampled flue gas to flow into the 50L water treatment solution in the graduated container at a flow rate of 30L / min, perform reaction and dust removal treatment, and start timing at the same time, at this time is 0; the water treatment solution in the scale container is 10% by weight CaCO 3 solution. Then, the flue gas after the water treatment solution reaction and dust removal treatment is passed into the Zeeman effect mercury analyzer to detect the mercury co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com