Method for selectively doping emitting stage on surface of crystalline silicon cell film

A technology on the surface of crystalline silicon cells and silicon wafers, applied to circuits, electrical components, semiconductor devices, etc., can solve problems such as difficulty in further improvement, limitation of cell conversion efficiency, lack of selective emission levels, etc., and achieve an increase in conversion efficiency , Improve the conversion efficiency, the effect of large profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A specific embodiment of the present invention will be described below by taking a monocrystalline silicon solar cell as an example.

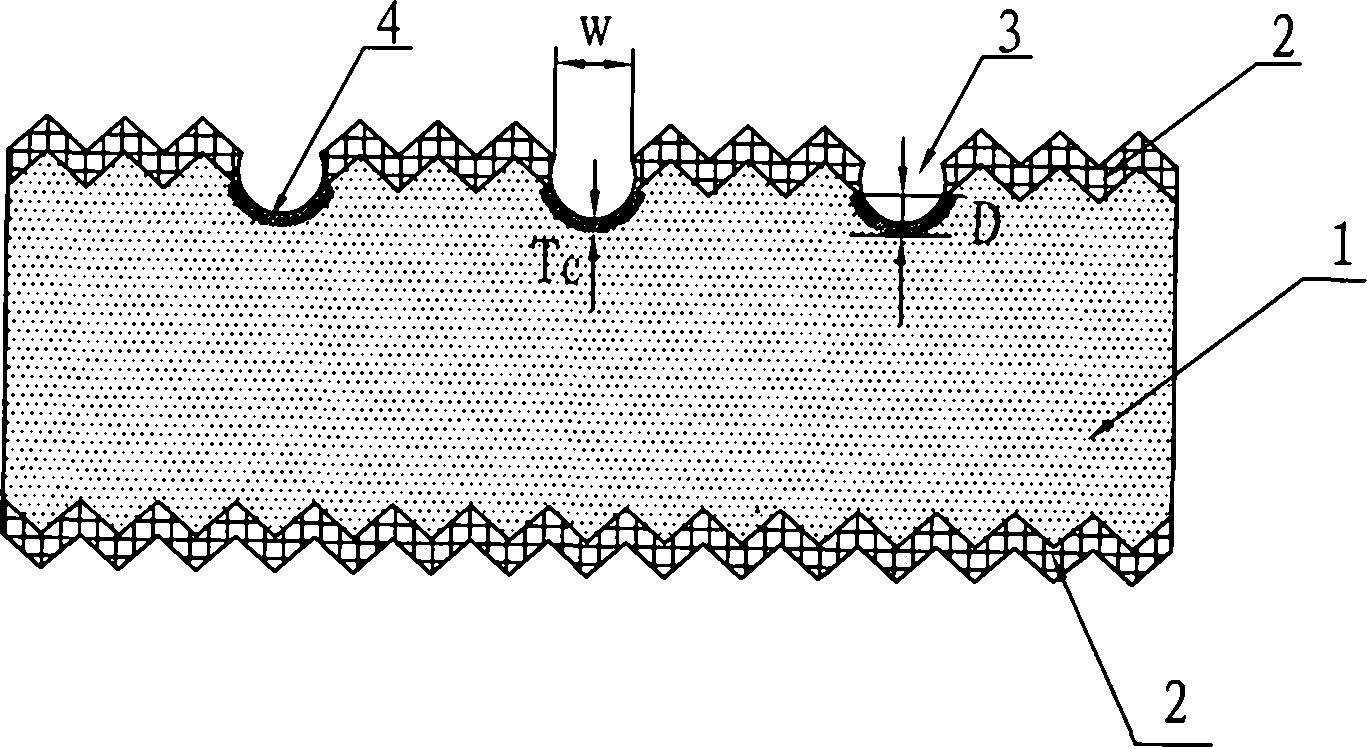

[0034] attached figure 1 ~ attached Figure 11 as the main production process.

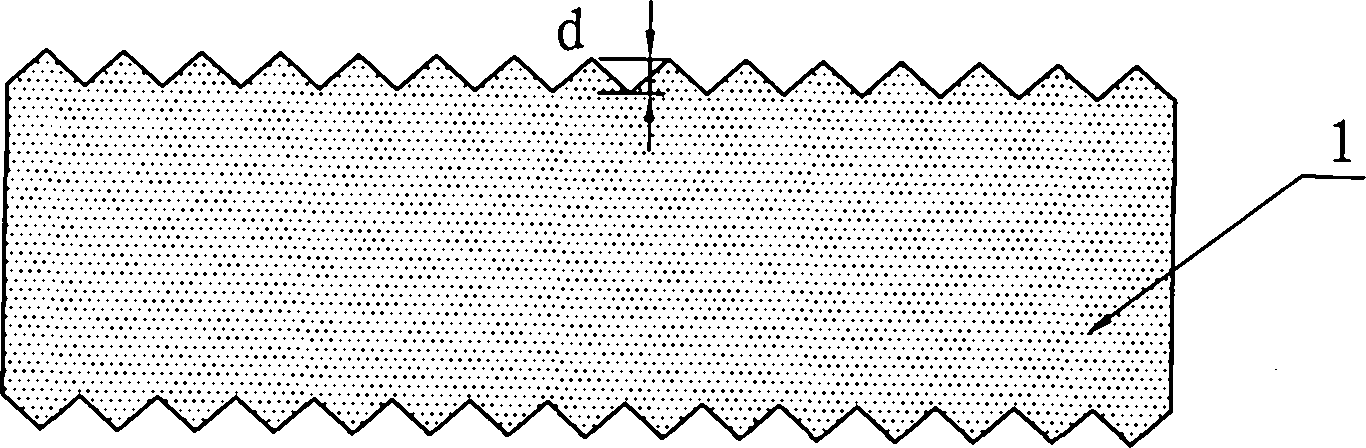

[0035] figure 1 is a schematic diagram of the structure of p-type monocrystalline silicon wafer 1 after texturing treatment, in figure 1 Among them, the thickness of the p-type single crystal silicon wafer 1 is 180-200 microns, and its resistivity is between 1-5 ohm·cm. After texturing, the depth d formed on the upper and lower surfaces of the p-type single crystal silicon wafer 1 is 3-5 micron suede;

[0036] The present invention starts from the p-type monocrystalline silicon chip 1 after the texturing treatment, and its specific steps are as follows:

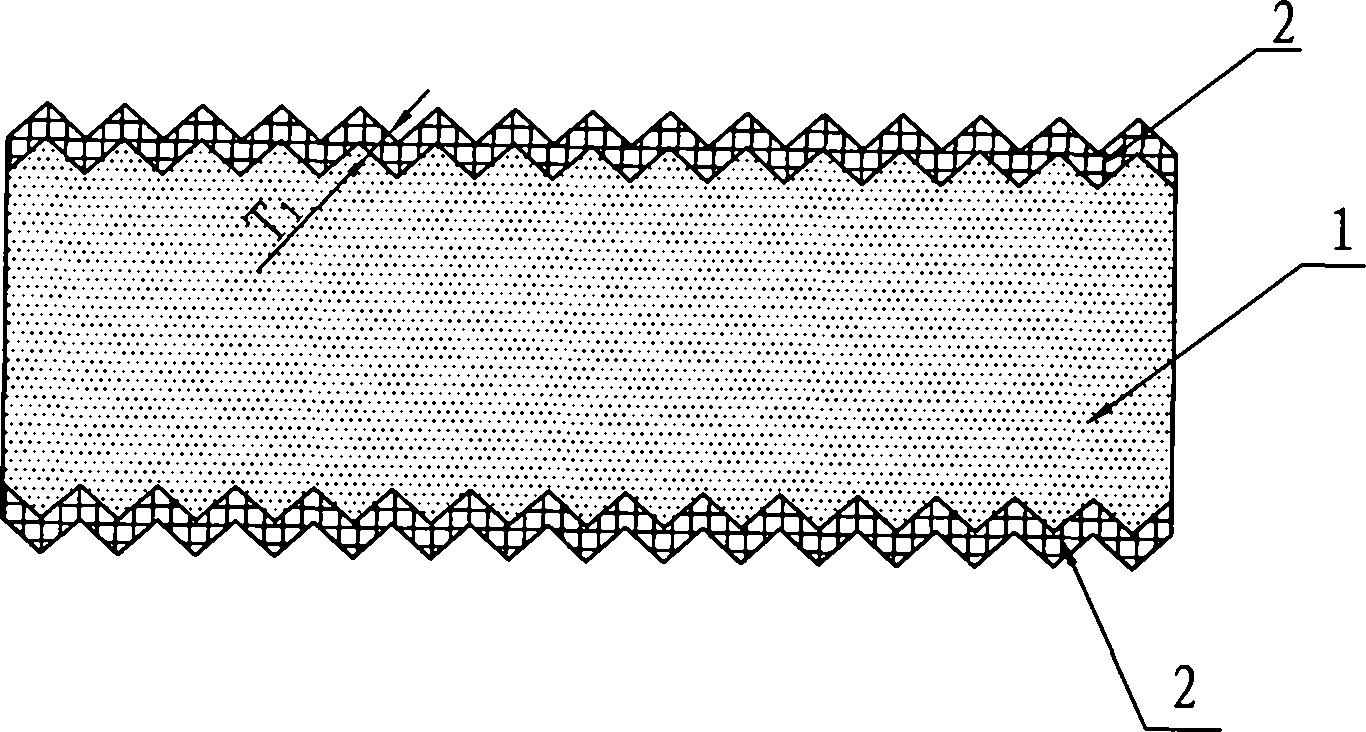

[0037] The first step, dry masking: put the textured silicon wafer 1 into an oxidation furnace at 1000°C-1100°C, pass in oxygen for dry oxidation, the oxidation time is 10 minutes, and epitaxy on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com