Preparation method of epitaxial iron-based superconducting thin film and prepared epitaxial iron-based superconducting thin film

A technology of iron-based superconductivity and thin film, applied in the field of superconductivity, can solve the problem of insufficient physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

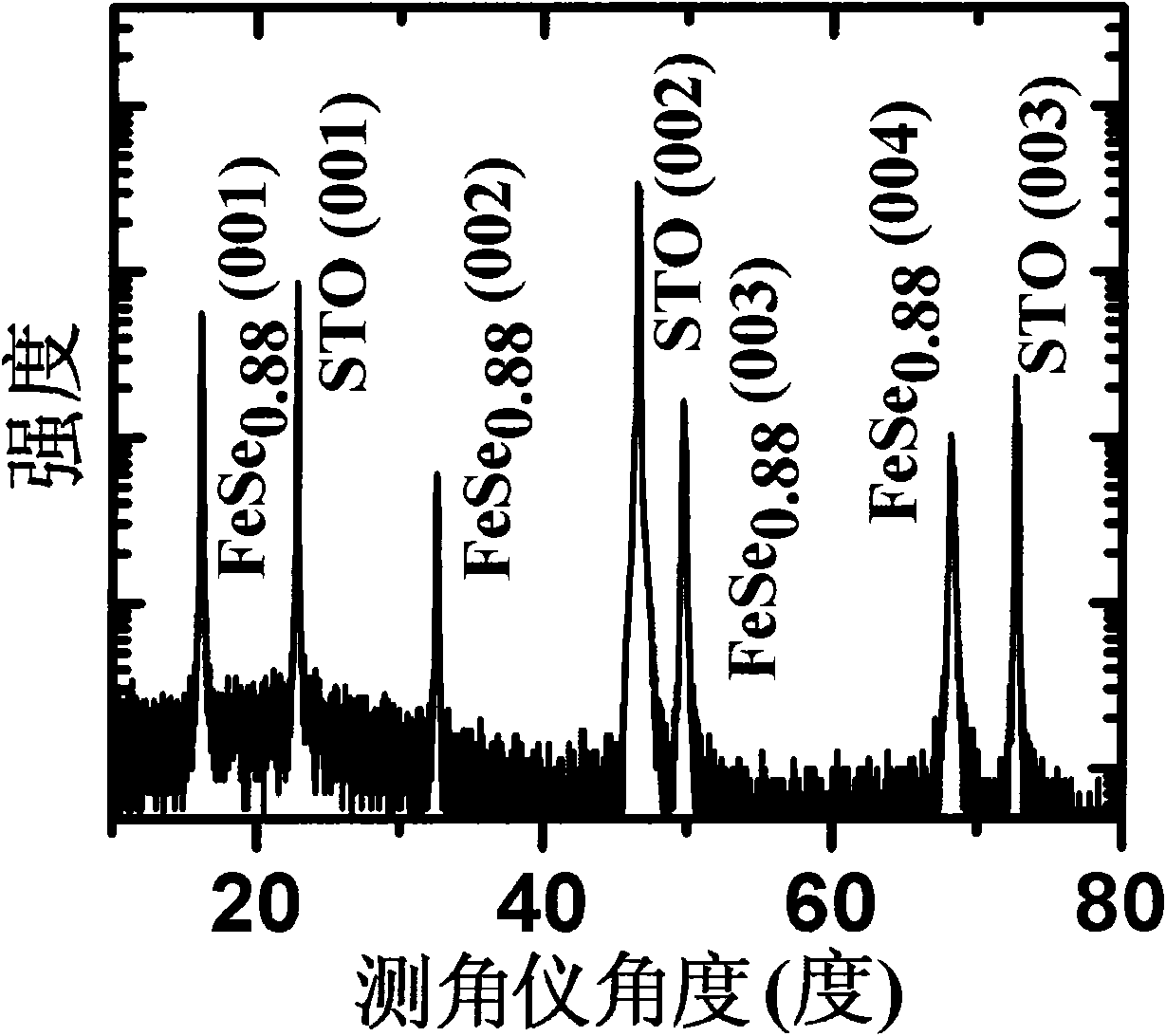

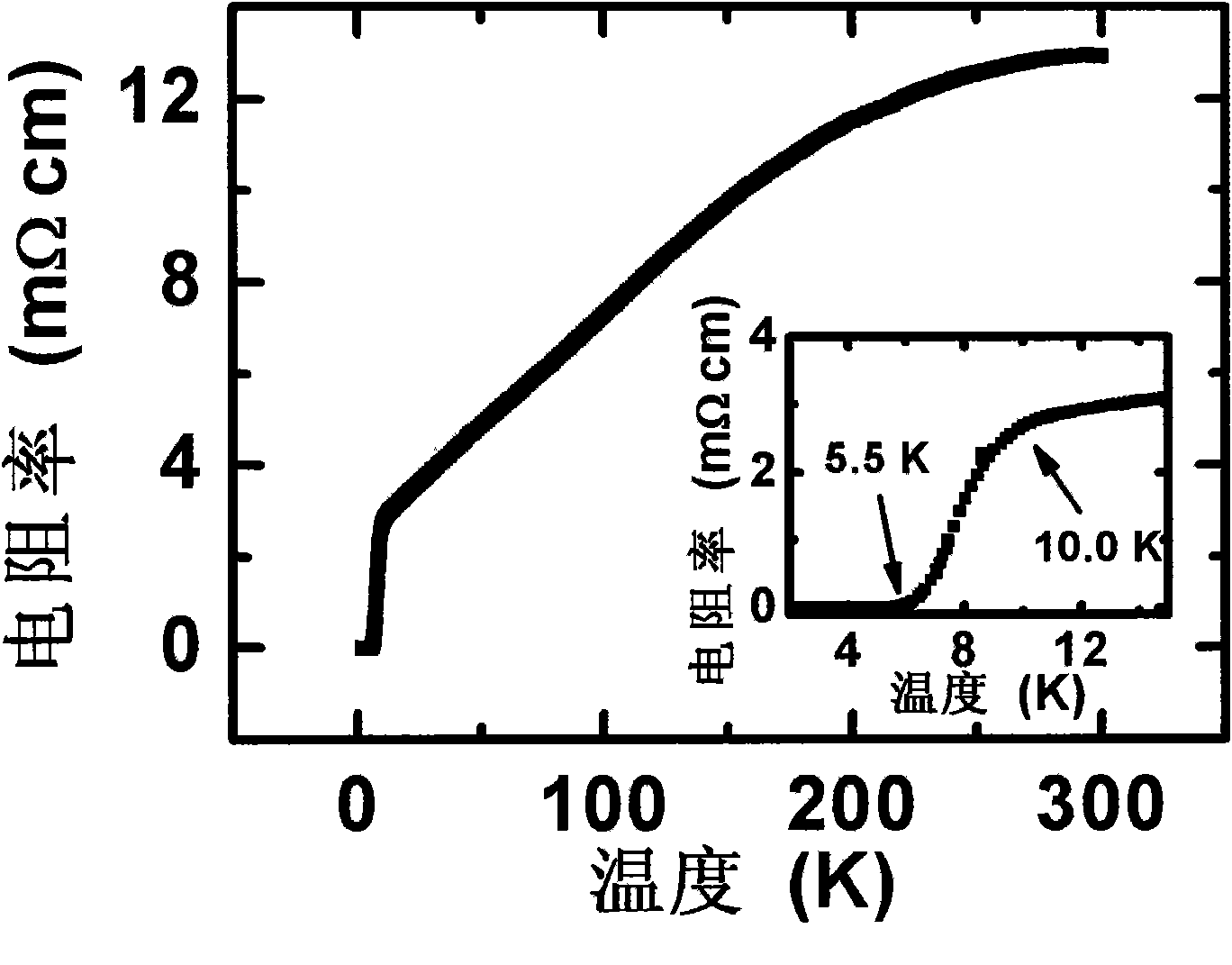

Embodiment 1

[0038] 1) First prepare FeSe 0.88 For the target (polycrystalline), mix Fe and Se powders with a molar ratio of 1:0.88 evenly, and vacuum-pack it with a quartz tube after pressing, and sinter at 600°C for 24 hours; after cooling down, take out the sintered target and crush it. After pressing the tablet again, vacuum seal it with a quartz tube. After sintering again at 700°C for 24 hours, lower the temperature to 380°C and anneal for 24 hours; put the sintered target into the vacuum chamber of the pulsed laser deposition system.

[0039] 2) SrTiO with (001) orientation 3 The single crystal substrate is ultrasonically cleaned with acetone for 10 minutes, then ultrasonically cleaned with alcohol for 10 minutes, dried with compressed air, fixed on the substrate table, and then put the substrate table into the vacuum chamber, the target and the substrate The distance is controlled at about 4cm.

[0040] 3) The vacuum degree in the vacuum chamber is better than 3×10 -4 Under the ...

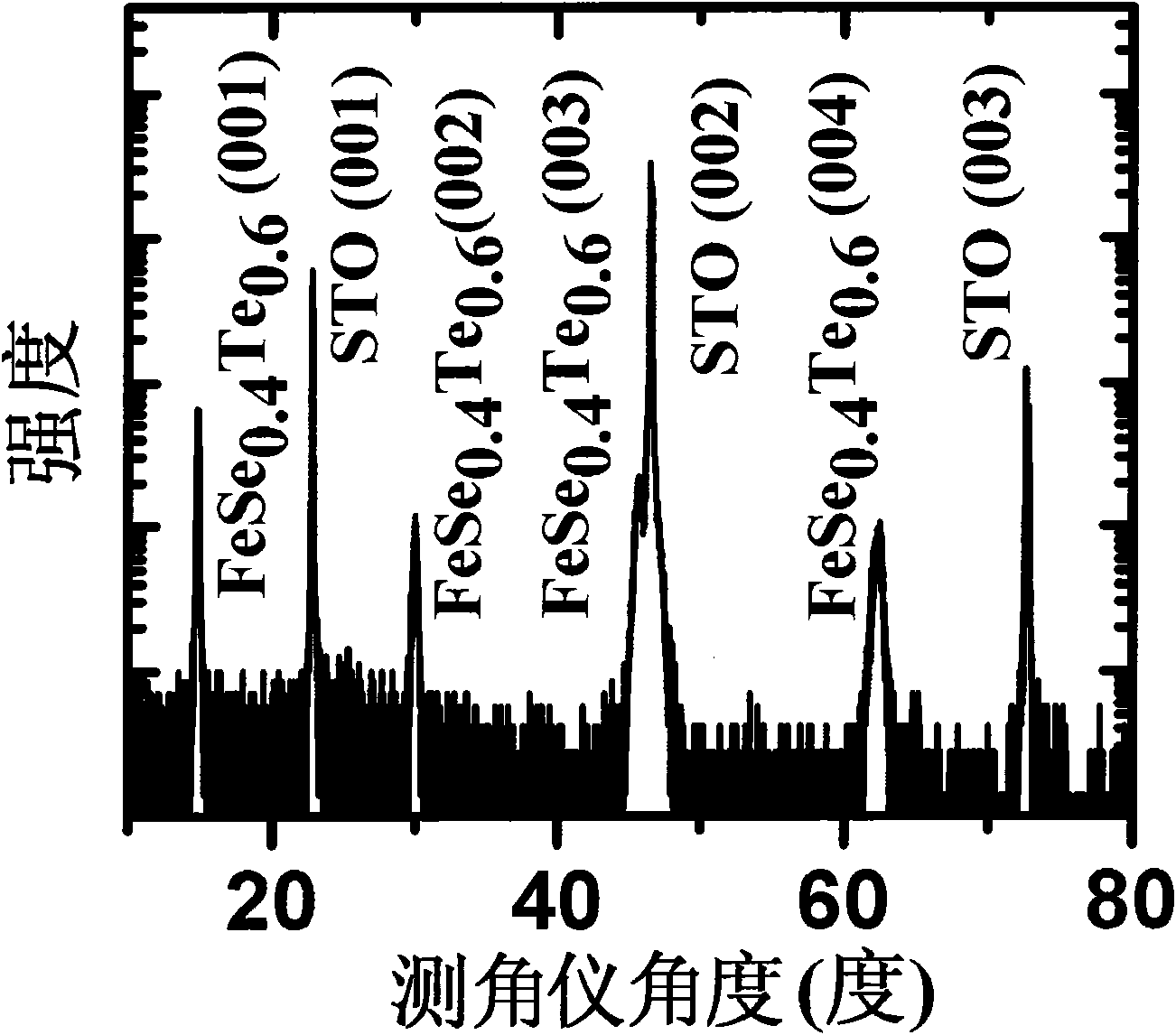

Embodiment 2

[0046] 1) First prepare FeSe 0.4 Te 0.6 For the polycrystalline target material, Fe, Se and Te powders with a molar ratio of 1:0.4:0.6 are mixed evenly, and after being pressed into tablets, they are vacuum-packed with a quartz tube and sintered at 600°C for 24 hours. The sintered target is crushed, pressed into pellets and vacuum-packed with a quartz tube. After re-sintering at 700°C for 24 hours, the temperature is lowered to 380°C for 24 hours for annealing. Put the sintered target into the vacuum cavity of the pulsed laser deposition system.

[0047] 2) (001) orientation SrTiO for substrate 3 The single crystal substrate is ultrasonically cleaned with acetone for 10 minutes, then ultrasonically cleaned with alcohol for 10 minutes, dried with compressed air, fixed on the substrate table, and then put the substrate table into the vacuum chamber, the target and the substrate The distance is controlled at about 4cm.

[0048] 3) The vacuum degree in the vacuum chamber is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com