Duplex-structure foamed ceramic filter plate, manufacture method thereof and aluminum melt filtering device

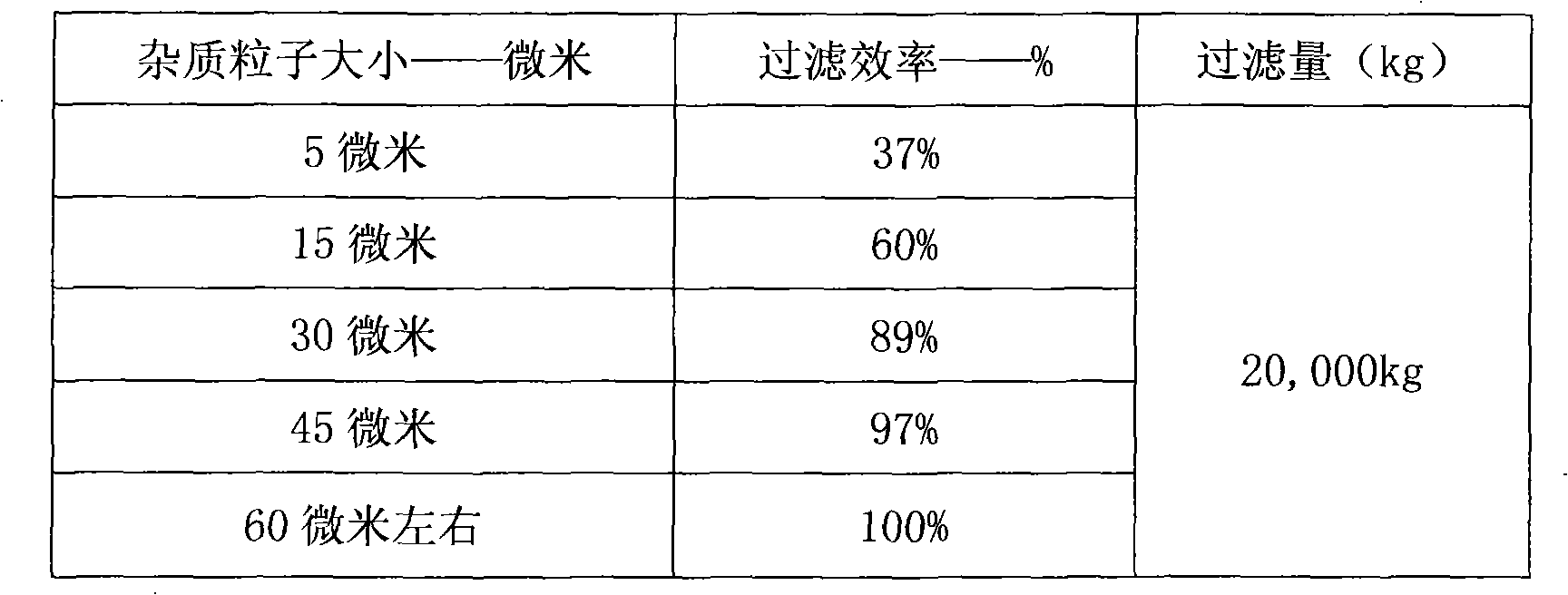

A foamed ceramic filtration and foamed ceramic plate technology, which is applied in ceramic products, fixed filter element filters, separation methods, etc., can solve the problems that the filter plate is not easy to radiate heat, limit the flow of aluminum melt, and inconvenient to filter aluminum melt. , to achieve the effect of reducing board floating, strong production flexibility, and improving tearing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention mixes 37kg aluminum dihydrogen phosphate, 1.5kg fumed white carbon black, 1.5kg kaolin, 1.5kg aerogel, 57kg alpha alumina, 1.5kg defoamer, and 0.7kg dispersant to make slurry, and then The mixed slurry is extruded into the foam mold, the formed filter plate is baked, and then the baked filter plate is sintered to form a foam ceramic filter plate.

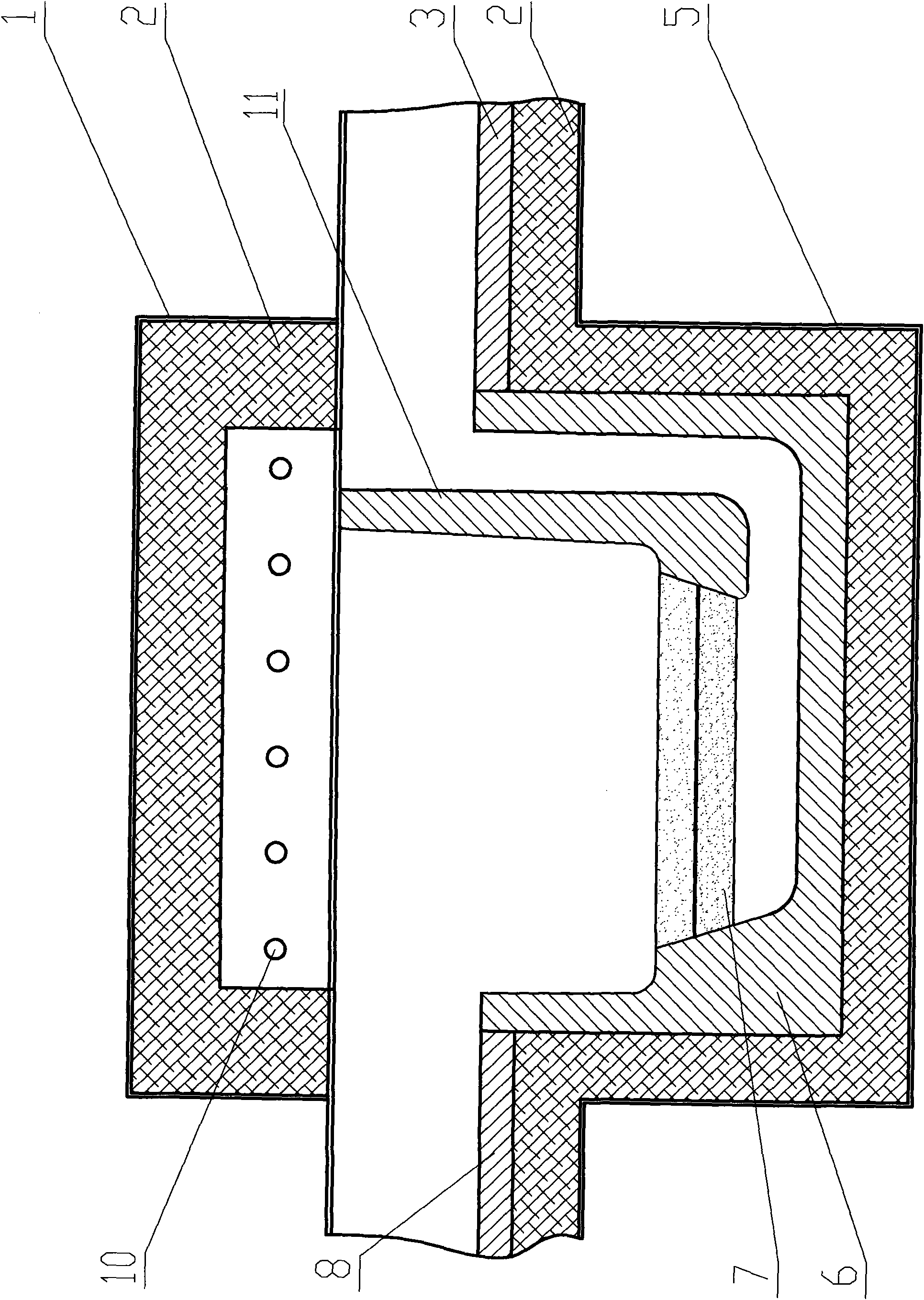

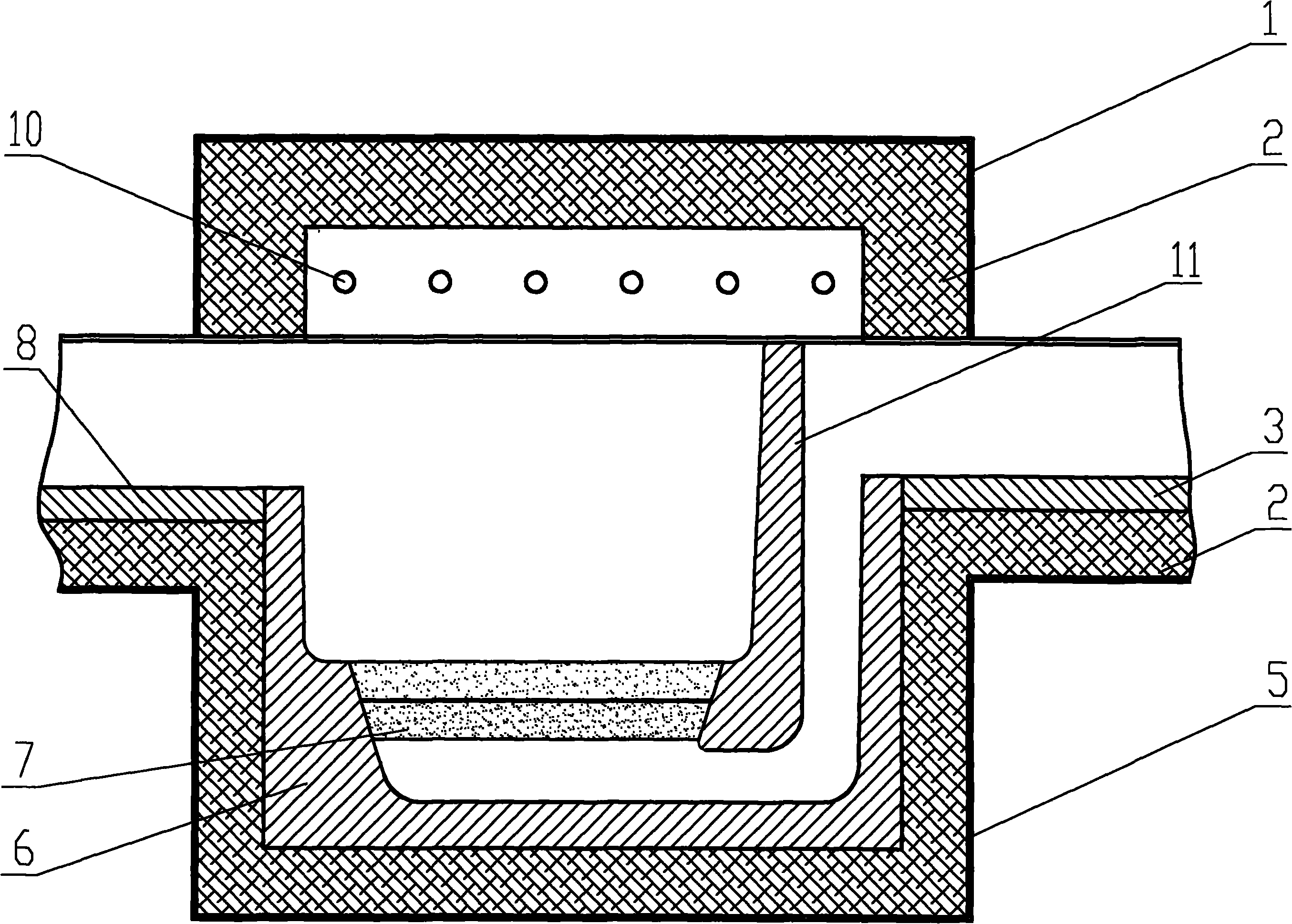

[0017] Filtration device of the present invention comprises:

[0018] Box 5, the space for filtering aluminum melt is set in the box, the aluminum melt inlet launder 9 is set on one side of the box body, and the aluminum melt outlet launder 3 is set on the other side of the box body, wherein: box body 5 aluminum melt A foam ceramic filter plate 7 is arranged in the filter space, and the inlet launder 9 of the box body 5 is connected to the space equipped with the foam ceramic filter plate 7. The tube core of the foam ceramic filter plate 7 is connected to the outlet launder 3 of the box body 5, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com