Resin composition for printed circuit board and printed circuit board using the same

A resin composition, printed circuit board technology, applied in the direction of printed circuit dielectric, printed circuit, printed circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

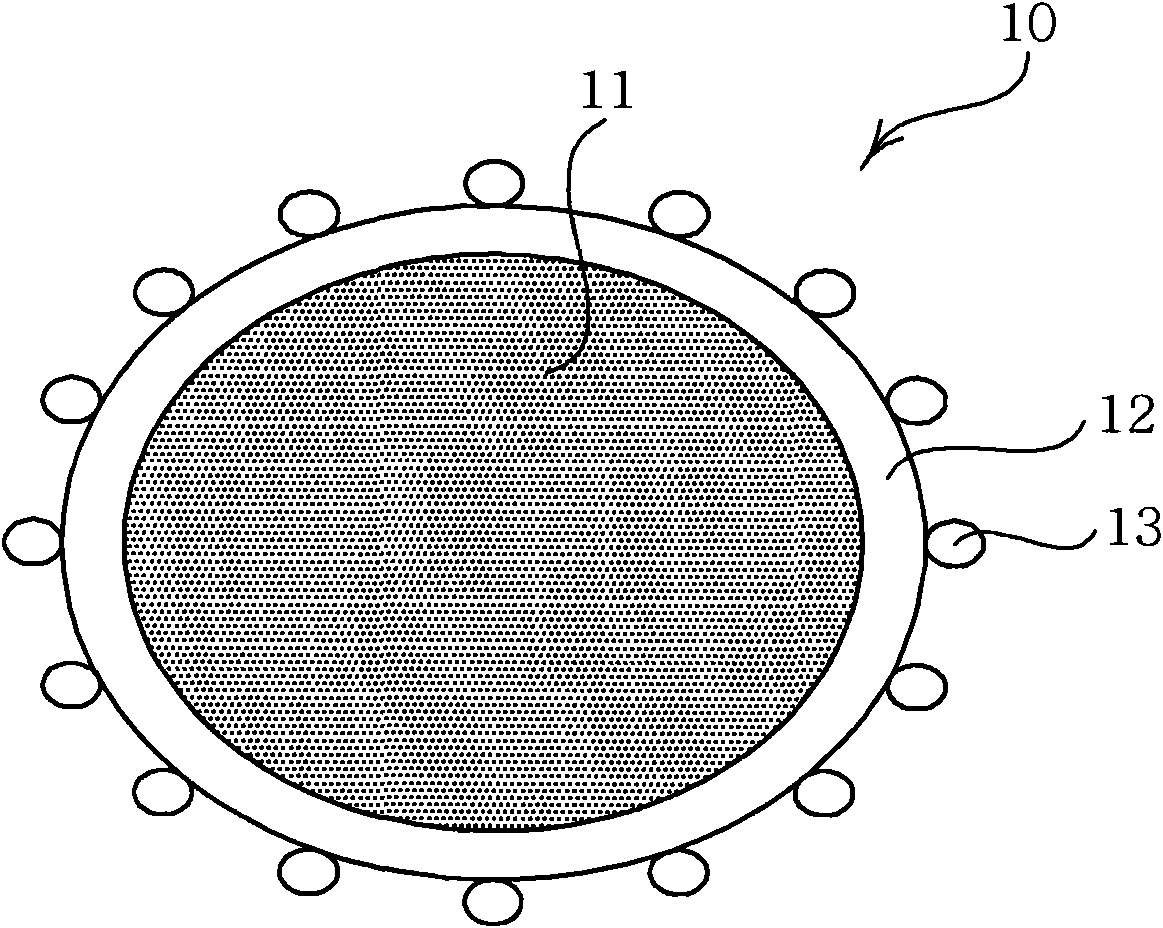

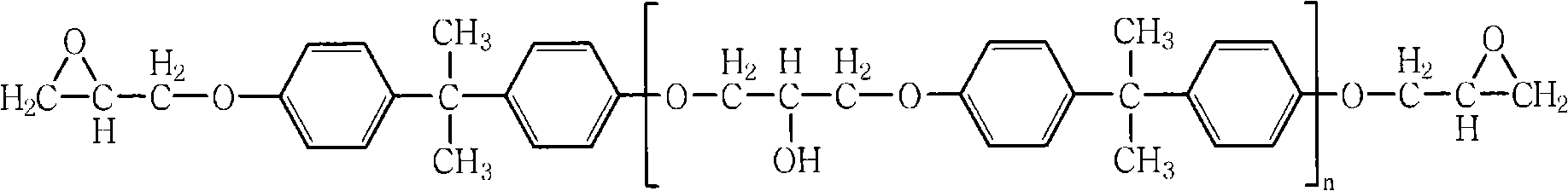

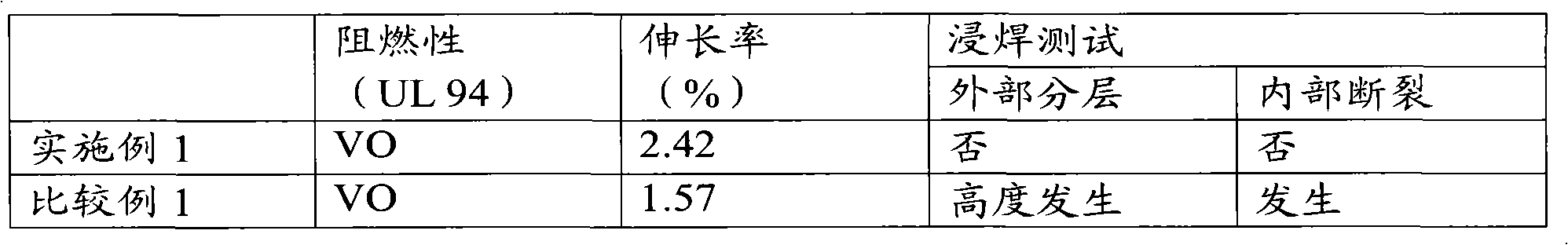

[0055] 375 g of bisphenol A epoxy resin obtained by dispersing 40 wt % of silicone elastomer particles having a core-shell structure with an average particle diameter of 1 μm in DGEBA epoxy resin with an average epoxy resin equivalent weight of 302 , 750 grams of cresol novolac epoxy resin with an average epoxy equivalent weight of 206, 375 grams of a flame retardant epoxy resin with an average epoxy equivalent weight of 590, and 992.76 grams of 66.7 wt% bisphenol A phenolic resin (novolac resin) curing agent (solvent: 2-methoxyethanol) was added to a mixed solvent of 239.54 g of MEK and 501 g of 2-methoxyethanol, and stirred at room temperature at 300 rpm. After that, 442.85 g of an inorganic filler having an irregular shape with a size distribution of 2.53 μm was added thereto, and the mixture was stirred at 400 rpm for 3 hours. Finally, 0.25 parts by weight of 2-ethyl-4-methylimidazole was added thereto, and the mixture was stirred for 1 hour, thereby preparing an insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com