Electrochemical aluminum hot stamping adhesive agent and preparation method thereof

An adhesive, anodized aluminum technology, applied in the direction of adhesive types, polymer adhesive additives, monocarboxylic acid ester copolymer adhesives, etc., can solve the problem of unsatisfactory wear resistance and water washing resistance of printable patterns and other problems, to achieve the effect of good market application prospects, excellent elasticity, simple storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

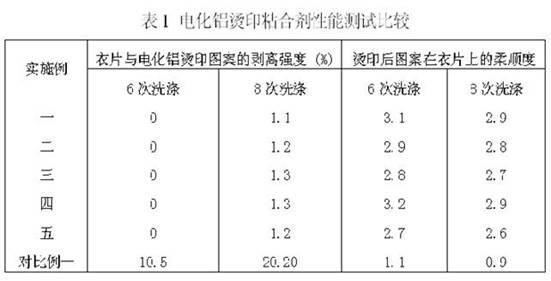

Examples

Embodiment 1

[0039] Weigh 1.6 parts of thermoplastic acrylic resin, 7.6 parts of EVA, and 22.7 parts of CEVA in parts by mass, dissolve them in 44.5 parts of xylene and 14.8 parts of isophorone mixed solvent, heat and stir to dissolve the resin; cool to 40°C, add 6.5 parts of poly Adhesion promoter for olefin plastics [produced by Eastman Company, brand CP343-3], stir and mix well; add 1.1 parts of fumed silica and 1.3 parts of organic bentonite and stir well to prepare anodized aluminum hot stamping adhesive mixture.

Embodiment 2

[0049] Weigh 0.3 parts of thermoplastic acrylic resin, 21.1 parts of EVA, and 16.9 parts of HPE in parts by mass, dissolve in 20 parts of xylene and 15 parts of DBE mixed solvent, heat and stir to dissolve the resin; cool to about 30°C, add 10 parts of CP343-3 Mix evenly; add 1.1 parts of fumed silica and 1.5 parts of organic bentonite and stir well to prepare an anodized aluminum hot stamping adhesive.

Embodiment 3

[0051] Weigh 3.3 parts of thermoplastic acrylic resin, 14.7 parts of EVA, and 14.8 parts of CEVA in parts by mass, dissolve them in 44.6 parts of xylene and 14.5 parts of isophorone mixed solvent, heat and stir to dissolve the resin; cool to about 50°C, add 6.6 parts of poly Adhesion promoter for olefin plastics [manufactured by Hangzhou Yiwei Coating Chemical Co., Ltd., brand MY343-40] and mixed evenly; add 1.1 parts of fumed silica and 1.4 parts of organic bentonite and stir well to prepare anodized aluminum hot stamping adhesive mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com