Method and device for making charcoal in array kilns and extracting flue gas

An extraction device and flue gas technology, which are applied in the field of carbon making methods and devices, can solve the problems of low carbon yield, large loss of raw materials, inconvenience for classification and extraction of flue gas, etc., and achieve the effects of good purity and simplified extraction equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the present invention.

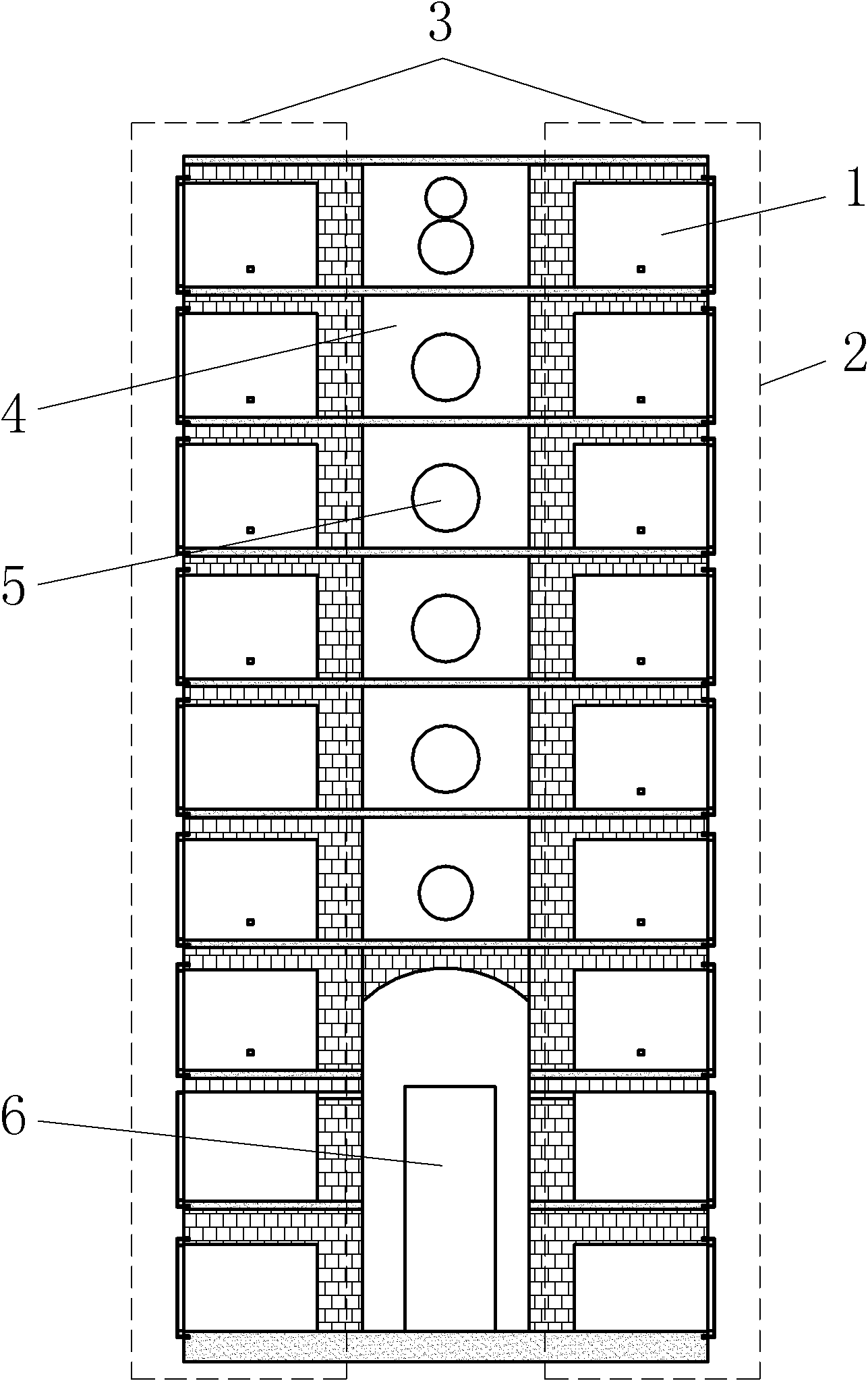

[0021] Example. A method for making charcoal and extracting flue gas in an array kiln such as figure 1 As shown, this method is based on the difference in the composition of the flue gas produced at different temperature stages in the charcoal making process, setting up charcoal kilns corresponding to different flue gas compositions to form a charcoal kiln group, and sending the raw materials into each charcoal kiln for firing to obtain finished charcoal ; A cave dwelling is set between the two charcoal kilns, and flue gas with different components is extracted through the cave dwellings. The different smoke constituents include smoke of extractable substances and smoke of combustible smoke. The flue gas of the extractable substance and the combustible flue gas respectively corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com