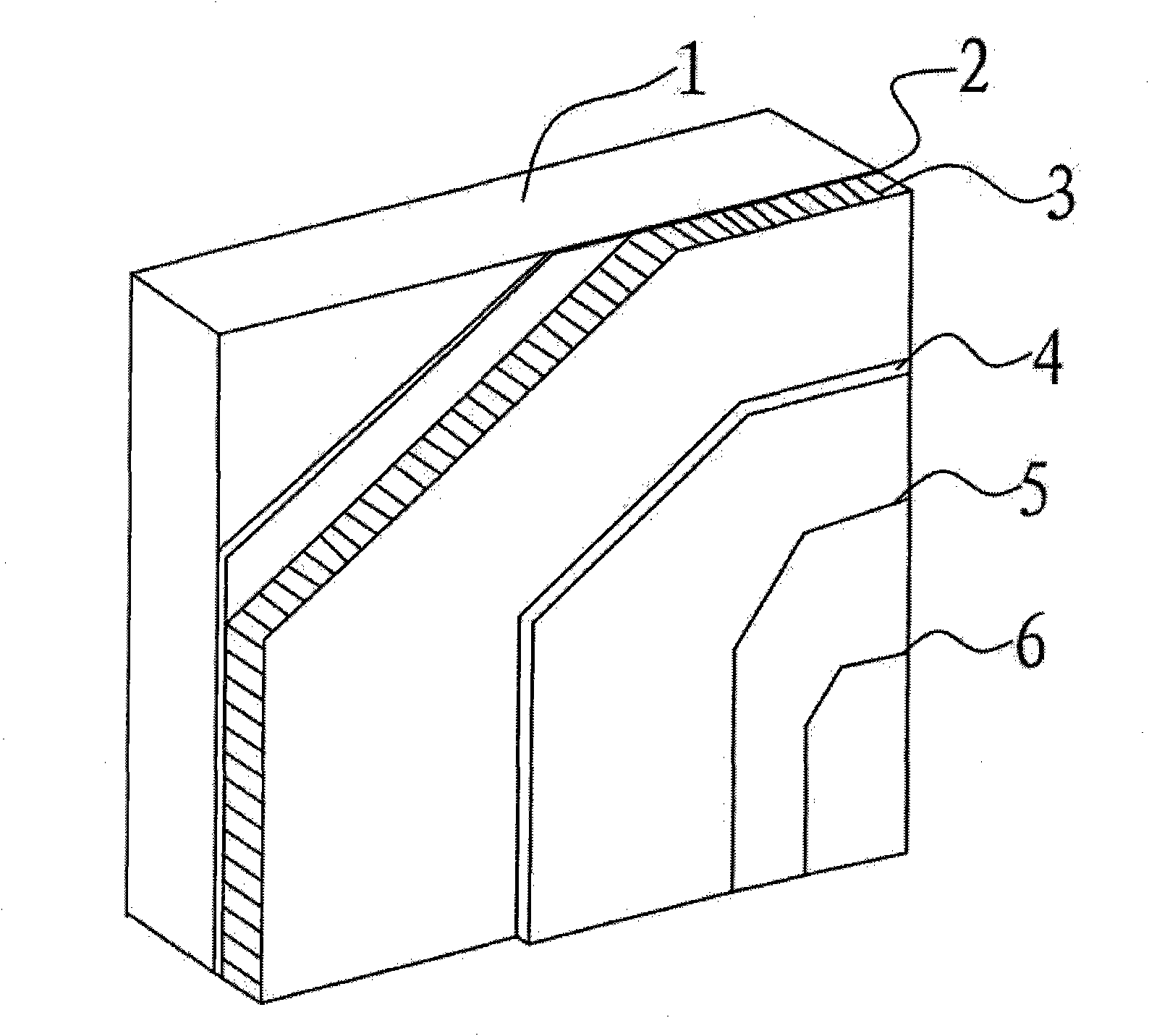

Exterior wall insulated structure and building method thereof

An exterior wall insulation and exterior wall technology, which is applied in insulation, building construction, construction, etc., can solve the problems of wall shedding, shortening the service life of the wall, and inconvenient construction, so as to improve the service life and reduce the air gap , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

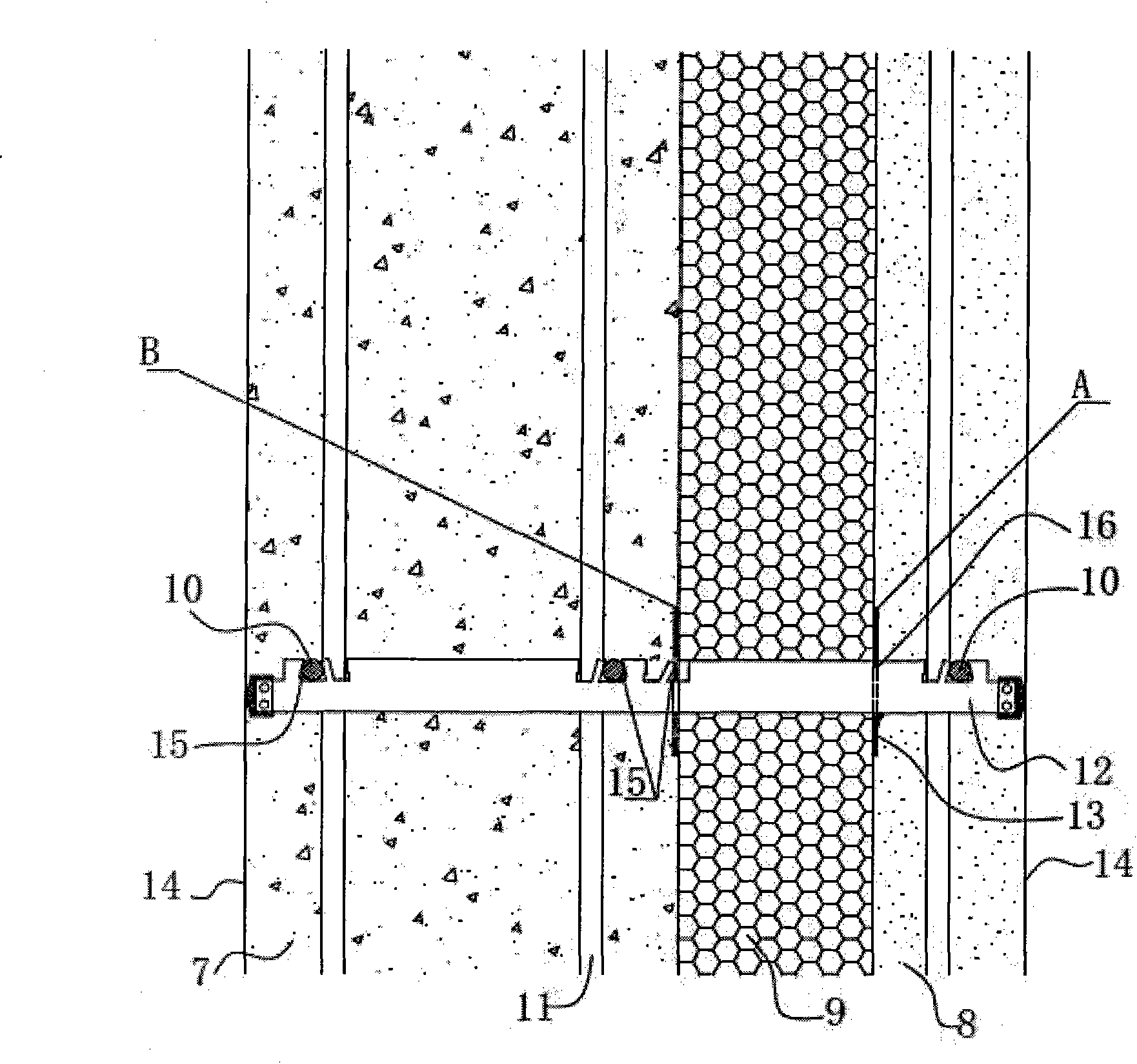

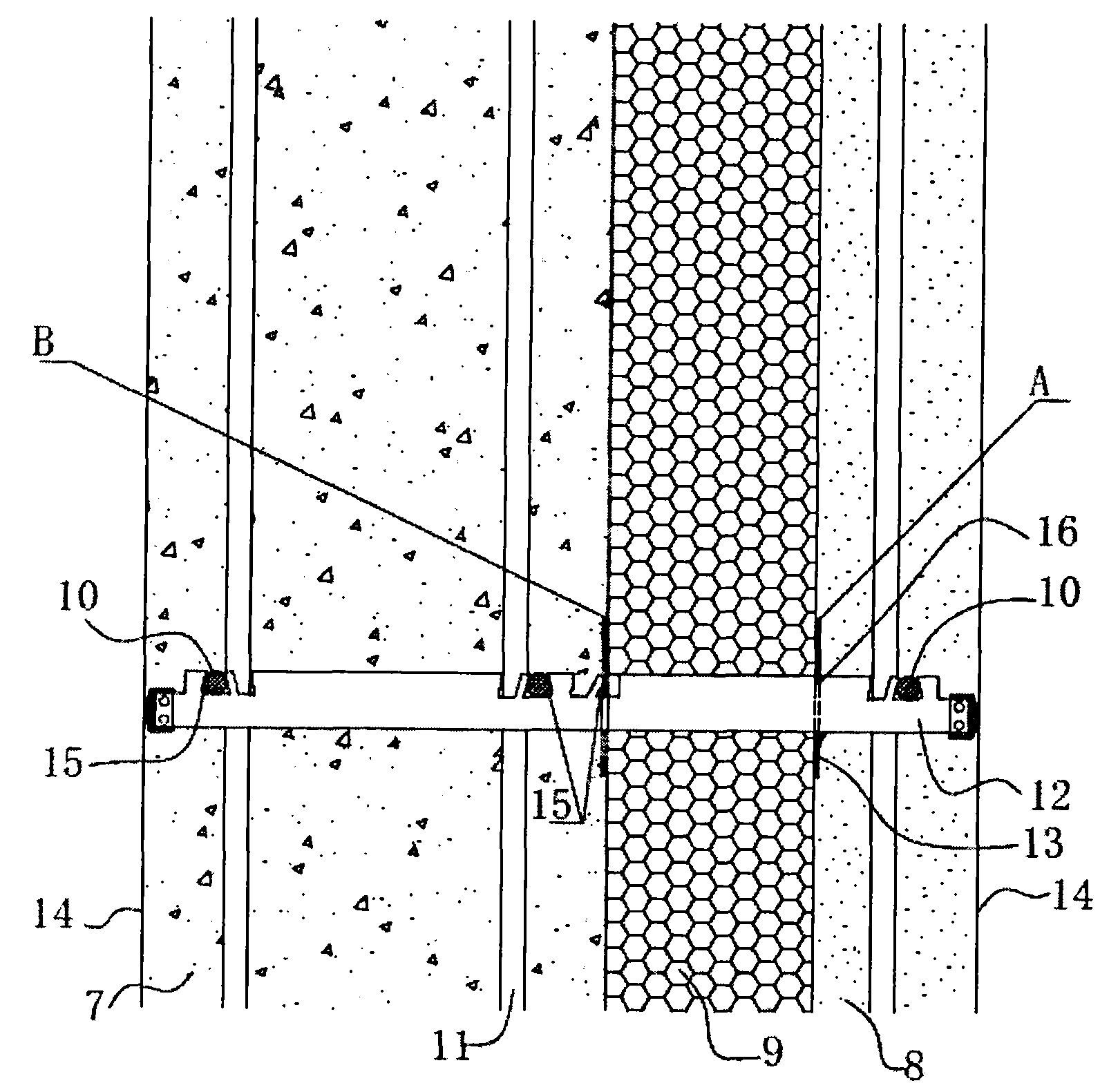

[0016] Below in conjunction with accompanying drawing, the present invention will be further described.

[0017] Such as figure 2 , the outer wall thermal insulation structure in the present invention comprises the inner layer 7 that is made of reinforced concrete, i.e. the indoor side of the wall; the outer side of the inner layer is provided with an outer layer 8 made of fiber cement mortar, i.e. the outdoor side of the wall; An insulation layer 9 is provided between the outer layer and the inner layer, and the insulation material is generally polystyrene material, which uses its excellent thermal insulation performance to insulate the indoor and outdoor heat; the inner layer and the outer layer are distributed with horizontal ribs 10 and The vertical vertical ribs 11 have mutual tension members 12 passing through the insulation layer 9, and fixedly connecting the horizontal ribs 10 and the vertical ribs 11 of the inner layer 7 and the outer layer 8. With this structure, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com