Optoisolator for use in fiber-optic communication

An optical isolator and optical fiber communication technology, which is applied to instruments, optics, nonlinear optics, etc., can solve the problems of large volume, increase the length of the optical path, and unsatisfactory performance, and achieve the effect of short optical path and reducing temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

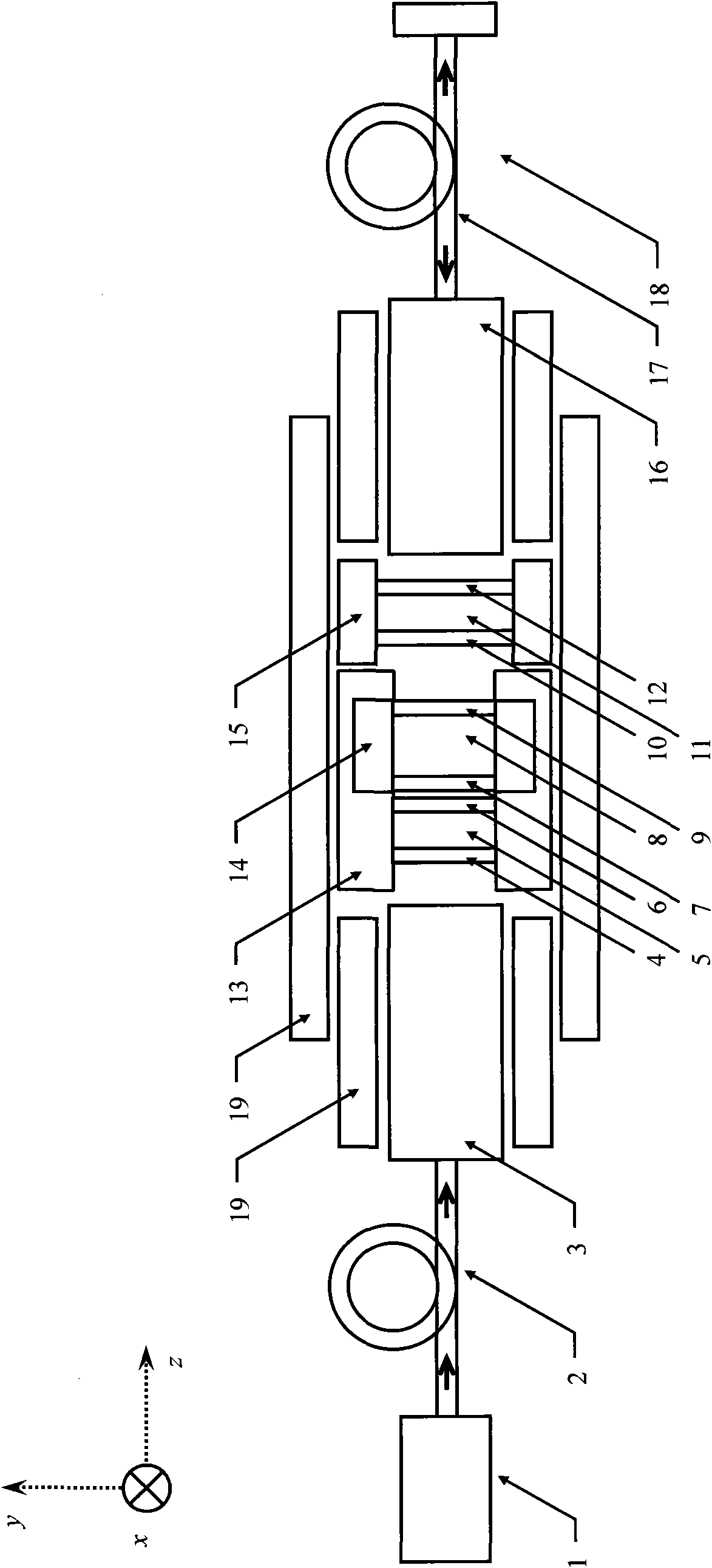

[0031] see figure 1, the present invention is applied in the optical fiber communication system as an integrated device, including a laser 1, an incident optical fiber 2, a first fiber collimator 3, a first linear polarizer 4, a first quarter-wave plate 5, a first Antireflection coating 6, first high reflectivity reflector 7, Faraday rotator 8, second antireflection coating 9, second high reflectivity reflector 10, second quarter wave plate 11, second linear polarizer 12 , a support body 13, a permanent magnet 14, a micro-displacement device 15, a second fiber collimator 16, an outgoing fiber 17, a reflector 18 and a sleeve 19. The Faraday rotator 8 is placed inside the permanent magnet 14, and its magneto-optical material is selected from yttrium iron garnet crystal (YIG), which is coated with a reflective film with a reflectivity of 92% on the end face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com