Copper-zinc alloy electroplating bath and plating method using the copper-zinc alloy electroplating bath

A technology of zinc alloy and electroplating bath, which is applied in the field of copper-zinc alloy electroplating bath, can solve the problems of cyanide toxicity and large burden of cyanide-containing waste liquid treatment, and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

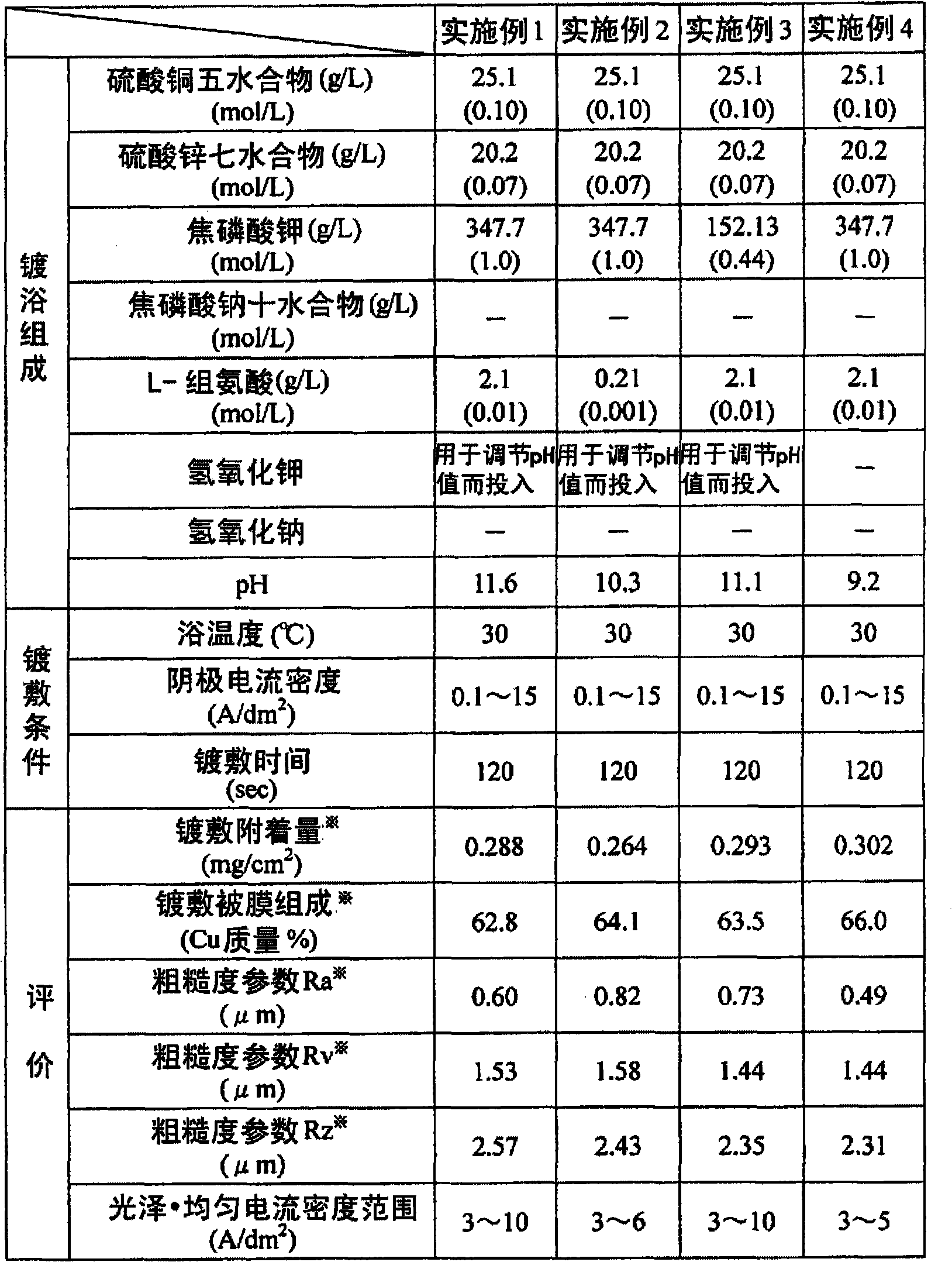

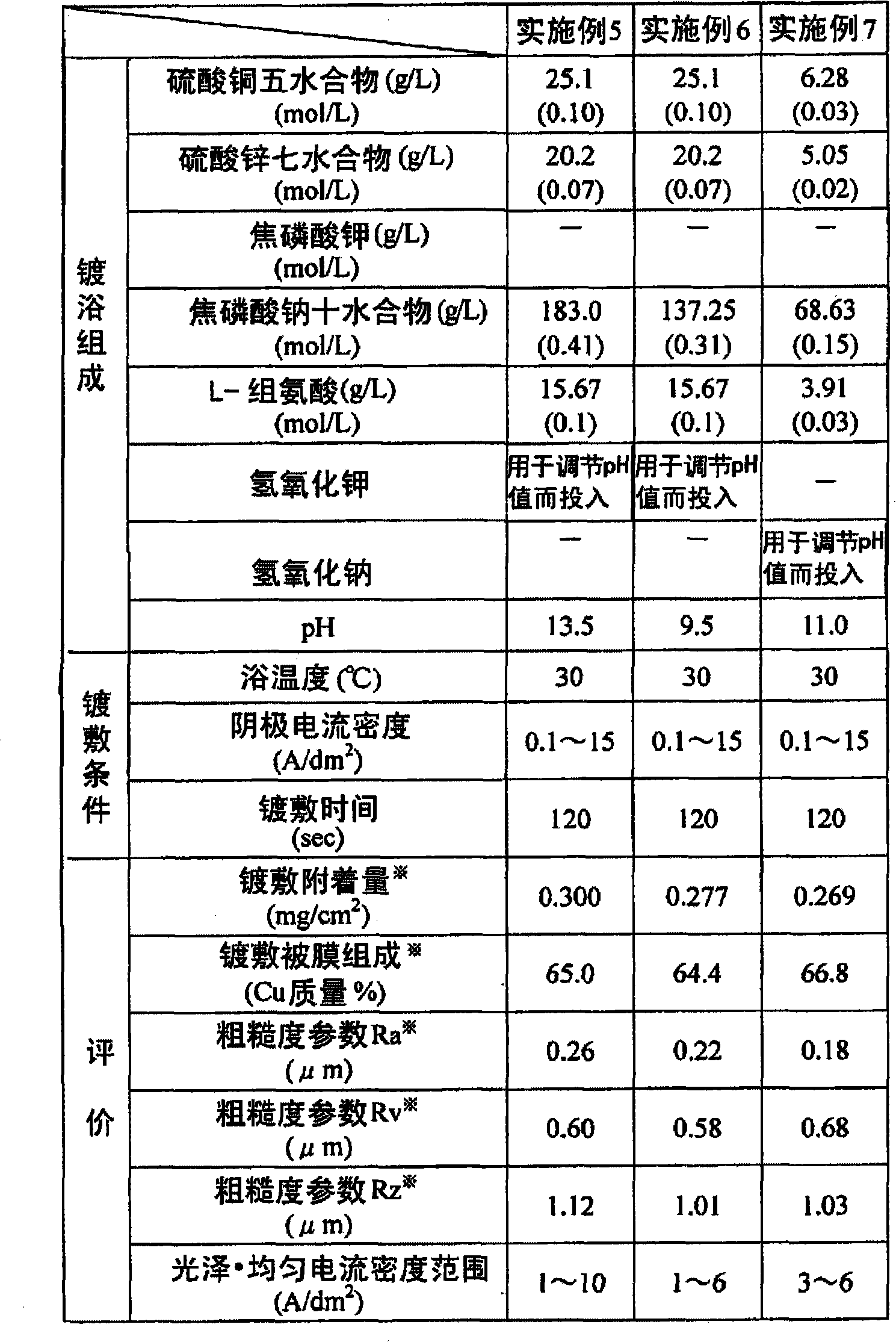

[0031] Hereinafter, the present invention will be described in more detail using examples.

[0032] According to the composition of the copper-zinc alloy electroplating bath shown in following tables 1~3 respectively, prepare the copper-zinc alloy electroplating bath of each embodiment; According to the plating condition in following table 1~3, carry out copper-zinc alloy electroplating bath Plating treatment. Immediately after preparing the plating bath, the plating treatment was carried out, and the plating deposition amount and alloy composition were analyzed. In addition, use a laser microscope to observe the roughness of the coating surface to obtain roughness parameters Ra, Rv, and Rz. At the same time, the current density range in which a glossy and uniform alloy layer can be obtained was obtained. The obtained results are collectively described in the following Tables 1-3.

[0033]

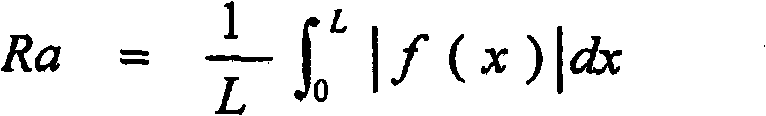

[0034] Ra was calculated from the following equation of the centerline average ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com