Bidirectional detection method of Young modulus and Poisson constant by ultrasonic surface wave

A technology of ultrasonic surface wave and Young's modulus, which is applied in the analysis of solids and other directions using sound waves/ultrasonic waves/infrasonic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below.

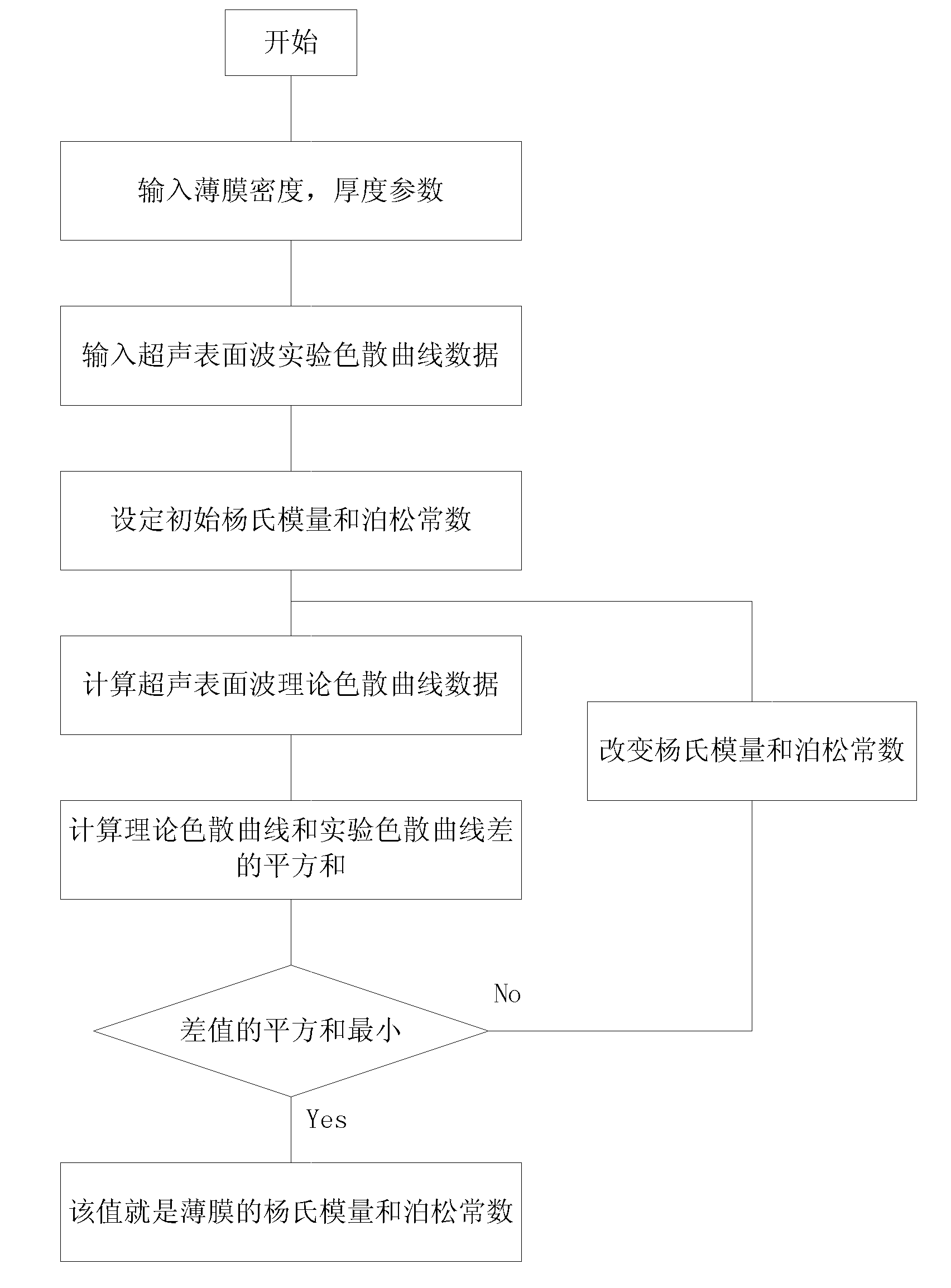

[0023] The two-way ultrasonic surface wave detection method proposed by the present invention can be implemented through the following three steps:

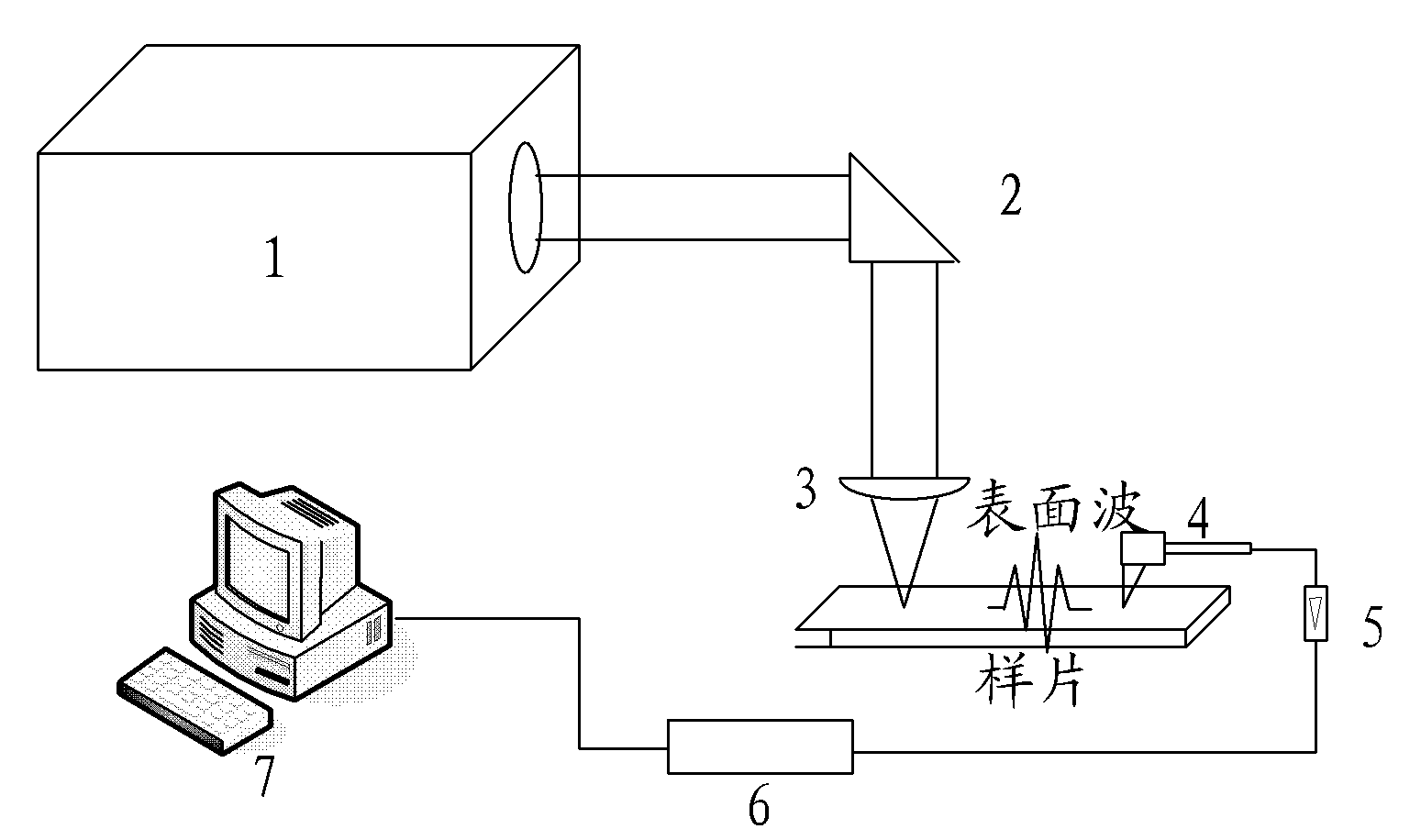

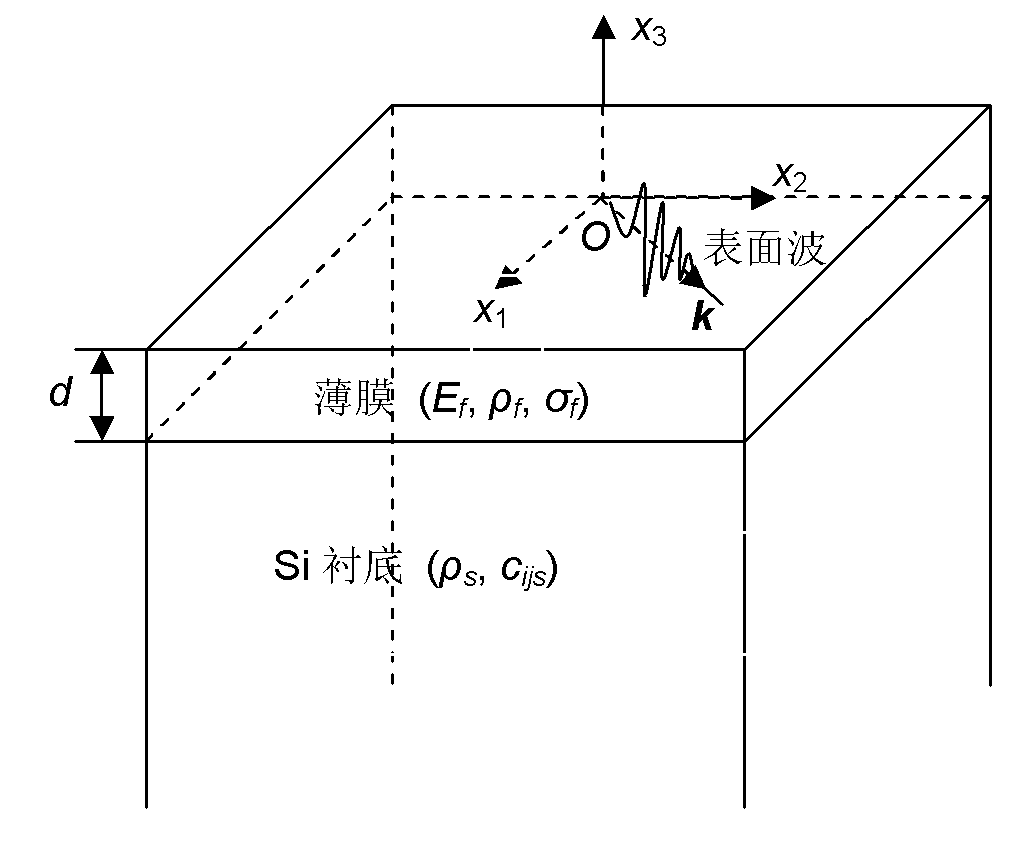

[0024] (1) Ultrasonic surface wave experimental dispersion curve measurement: A short-pulse laser is used to excite a broadband ultrasonic surface wave on the surface of the layered film material sample, and the surface wave signal is collected at two different positions on the surface of the sample through a piezoelectric detector. In this way, the dispersion curve of the ultrasonic surface wave propagating on the layered film material is calculated. figure 1 Shows a schematic diagram of an ultrasonic surface wave excitation and detection experimental system. The short-pulse laser light emitted by the laser 1 is reflected by the prism 2 and focused by the cylindrical mirror 3 to the surface of the sample, which excites ultrasonic surface waves. The piezoelectric dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com