Track type full-automatic automobile repairing and varnish baking device and control system

A vehicle maintenance, rail-type technology, applied in electrical program control, devices for coating liquid on surfaces, program control in sequence/logic controllers, etc., can solve problems such as low work efficiency, cumbersome operation, and high pollution , to achieve the effect of reducing labor intensity and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

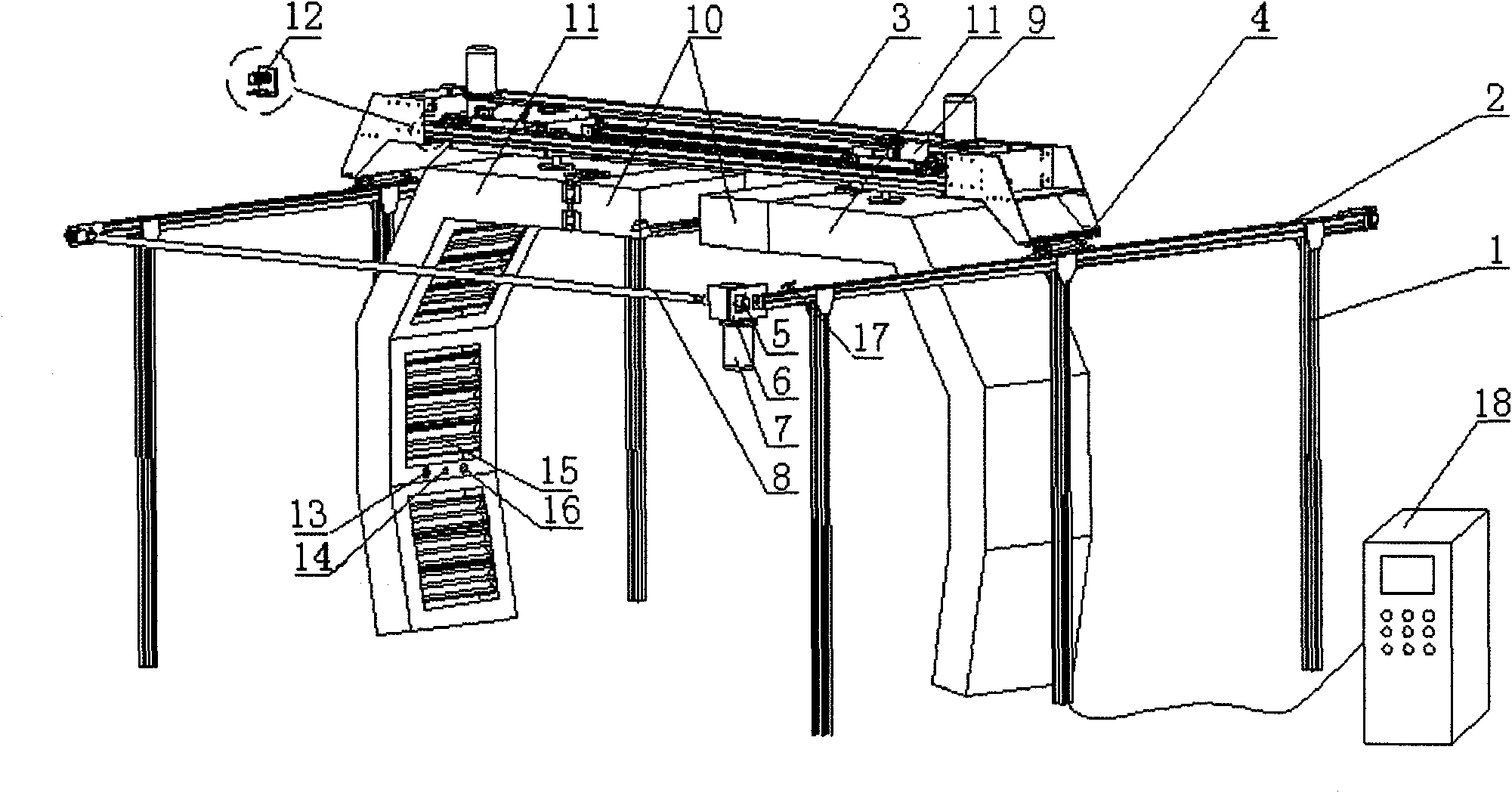

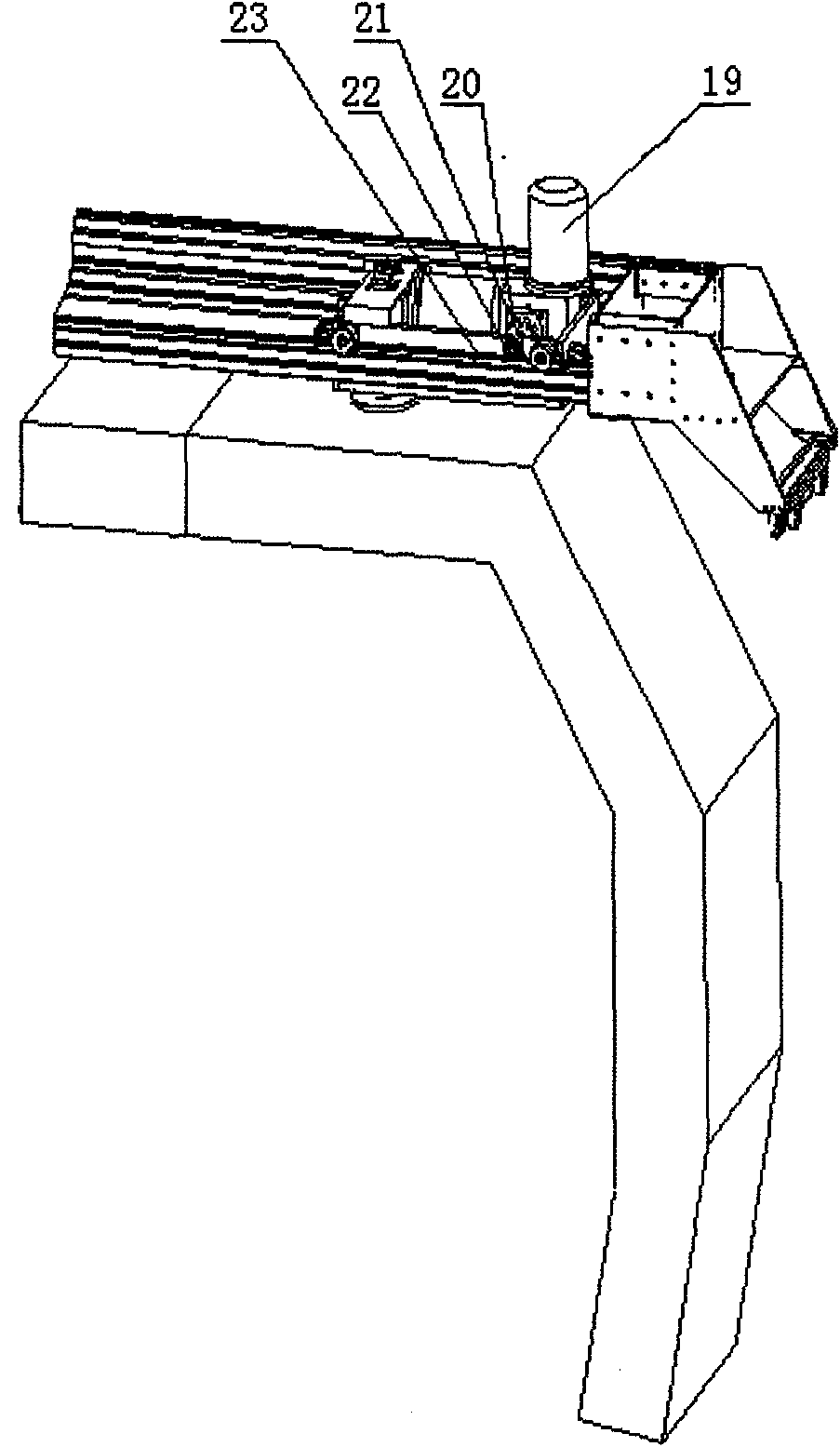

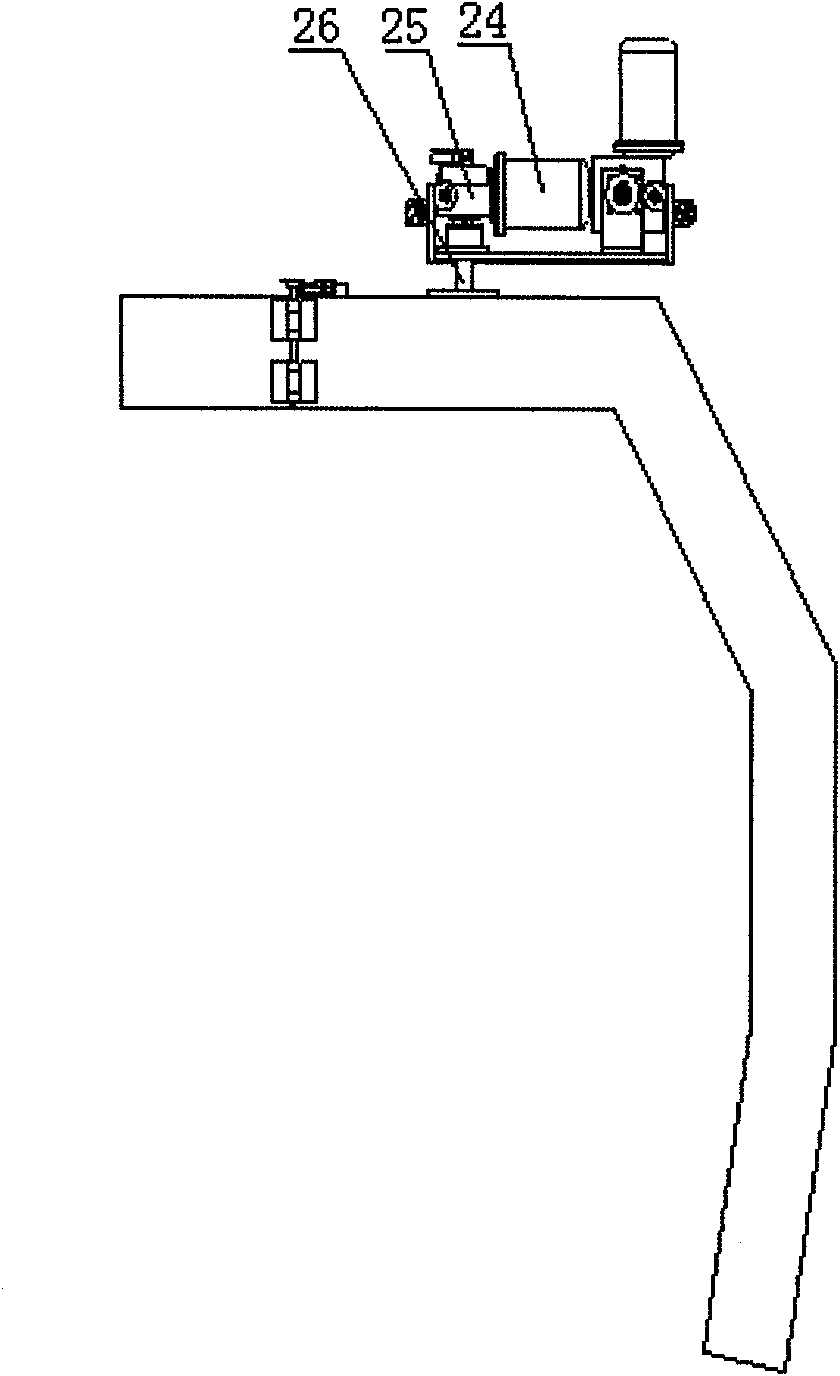

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown in , the track-type fully automatic car maintenance paint baking device is composed of a support mechanism composed of a column 1, a straight beam of a guide rail 2, and a beam assembly 3; an attached lamp body 10, an arched lamp body 11, a photoelectric sensor 14, and a short-wave infrared lamp assembly 15 , Infrared temperature sensor 13 and ultrasonic distance sensor 16 etc. constitute induction and work execution parts; Infrared temperature sensor 13 controls the working temperature of equipment; Proximity switch 12, travel switch 17 control the horizontal and vertical limit positions of lamp body movement; Photoelectric switch 14, Ultrasonic distance sensor 16 respectively detects and controls the longitudinal and lateral dimensions of the car to be painted; the longitudinal movement mechanism is composed of longitudinal sliding car 4, sprocket 5, reducer 6, motor 7, and drive shaft 8; hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com