Method for bonding fluoroplastic layer and polyester layer

A technology of fluoroplastic and polyester layer, which is applied in the bonding field of fluoroplastic layer and polyester layer, can solve problems such as long production cycle, achieve the effects of reducing environmental impact, unique conception, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

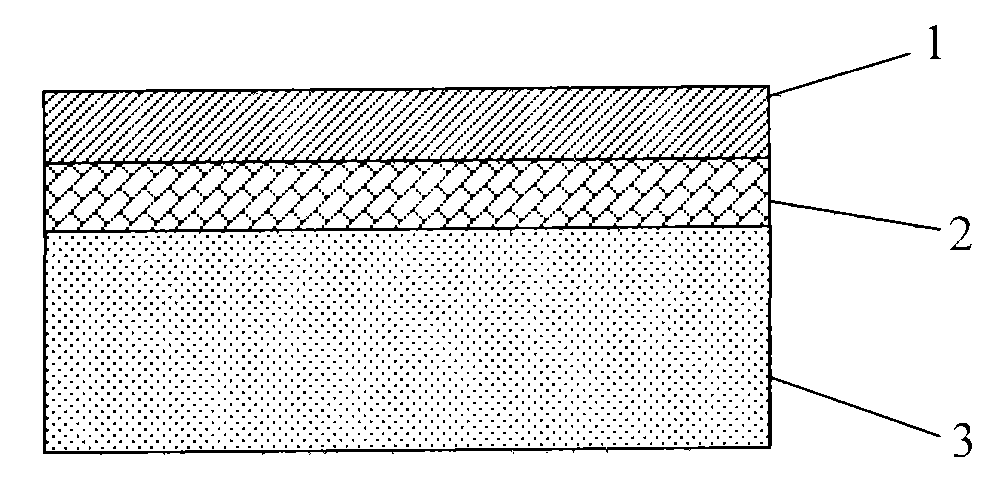

[0028] See figure 1 As shown, the fluoroplastic layer 1 is a PVDF layer, the adhesive layer 2 is an adhesive resin layer, and the polyester layer 3 is a PET layer. The structure is made through the following process: an extruder extrudes a film of the bilayer structure through a die, and then casts it onto the surface of the PET layer. The double-layer structure is a PVDF layer and an adhesive resin layer, and the adhesive resin layer is in contact with the surface of the PET layer. Wherein the PVDF layer is white and has a thickness of 20 μm. The adhesive resin layer was an ethylene maleic anhydride graft layer, and the thickness was 60 μm. The PET layer is a biaxially stretched PET layer with a thickness of 100 μm. According to the pulling force test, the bond strength between the bonding resin layer and the PET layer was 22 N / cm.

Embodiment 2

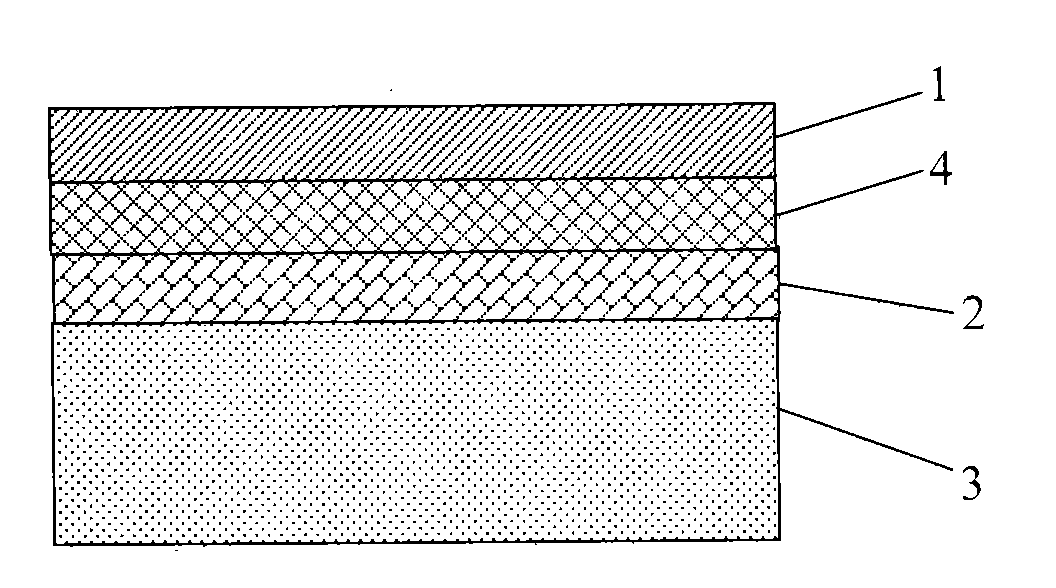

[0030] See figure 2As shown, the fluoroplastic layer 1 is a PVDF layer, the transition layer 4 is a mixture layer of PVDF and PMMA, the adhesive layer 2 is an adhesive resin layer, and the polyester layer 3 is a PET layer. The structure is made through the following process: an extruder extrudes a film of the three-layer structure through a die, and then casts it onto the surface of the PET layer. The three-layer structure is a PVDF layer, a mixture layer of PVDF and PMMA, and an adhesive resin layer, and the adhesive resin layer is in contact with the PET layer. Wherein the PVDF layer is white with a thickness of 5 μm. The content of PVDF in the transition layer 4 is 20%, the content of PMMA is 80%, and the thickness is 10 μm. The bonding resin layer is EMA with a thickness of 10 μm. The PET layer is a biaxially stretched PET layer with a thickness of 250 μm. According to the pulling test, the bonding strength between the bonding resin layer and the PET layer is 25 N / cm....

Embodiment 3

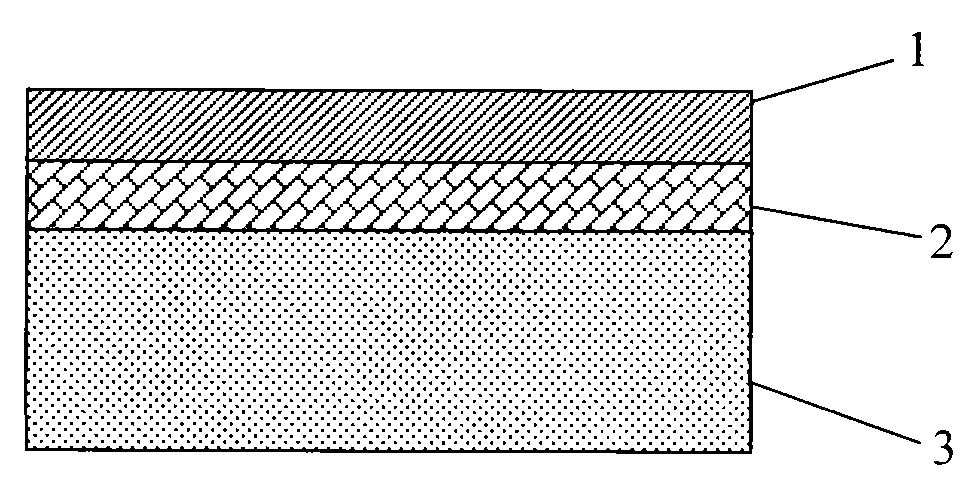

[0032] The fluoroplastic layer 1 is a PVDF layer, the adhesive layer 2 is an adhesive resin layer, and the polyester layer 3 is a PET layer. The structure is made by the following process: an extruder extrudes a film with a double-layer structure through a die, and then casts it onto the surface of the PET layer, which is pre-corona-treated. The double-layer structure is a PVDF layer and an adhesive resin layer, and the adhesive resin layer is in contact with the surface of the PET layer. Wherein the PVDF layer is white and has a thickness of 20 μm. The adhesive layer 2 is a mixture of EMA and PVDF, wherein the content of EMA is 95%, the content of PVDF is 5%, and the thickness is 60 μm. The PET layer is a biaxially stretched PET layer with a thickness of 100 μm. According to the pulling force test, the bond strength between the bonding resin layer and the PET layer was 25 N / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com