Non-hardened bainite cold heading steel for fastener and manufacturing method thereof

A manufacturing method and technology of cold heading steel, applied in non-quenched and tempered bainitic cold heading steel for high-strength fasteners of grade 10.9 and its manufacturing field, can solve problems such as increasing production costs, achieve cost saving, increase productivity, The effect of canceling the annealing and quenching and tempering heat treatment process

Inactive Publication Date: 2010-11-10

ANHUI UNIVERSITY OF TECHNOLOGY

View PDF6 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Chinese patent CN101619414 discloses a rolling method of 10.9-grade niobium-containing non-quenched and tempered cold heading steel and its hot-rolled wire rod. The main components are: C: 0.08-0.14%, Si: 0.03-0.35%, Mn: 1.80 ~2.30%, P≤0.025%, S≤0.015%, B: 0.0005~0.003%, Ti: 0.01~0.03%, Als: 0.010~0.050%, Nb: 0.02%~0.04%, but this patent adds niobium Nb alloy element, which increases the cost of production

[0007] Chinese patent CN101619420 discloses a rolling method of 10.9-grade chromium-containing non-quenched and tempered cold heading steel and its hot-rolled wire rod. The main components are: C: 0.08-0.14%, Si: 0.03-0.35%, Mn: 1.80 ~2.30%, P≤0.025%, S≤0.015%, B: 0.0005~0.003%, Ti: 0.01~0.03%, Als: 0.010~0.050%, Cr: 0.02%~0.04%, but the patent adds chromium Cr alloy element, which increases the cost of production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

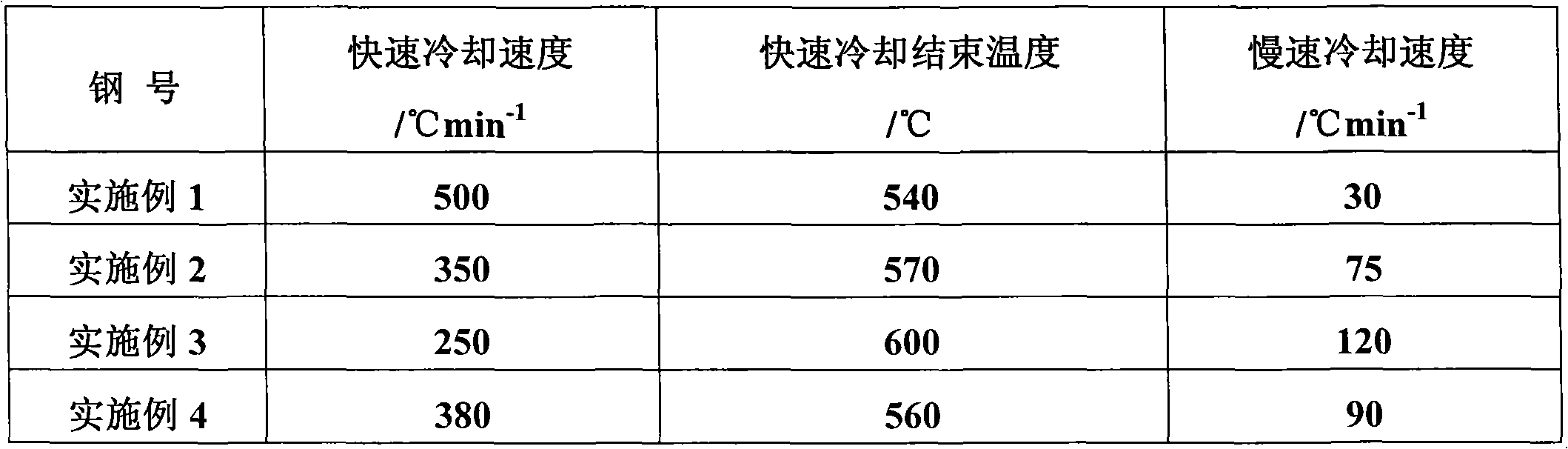

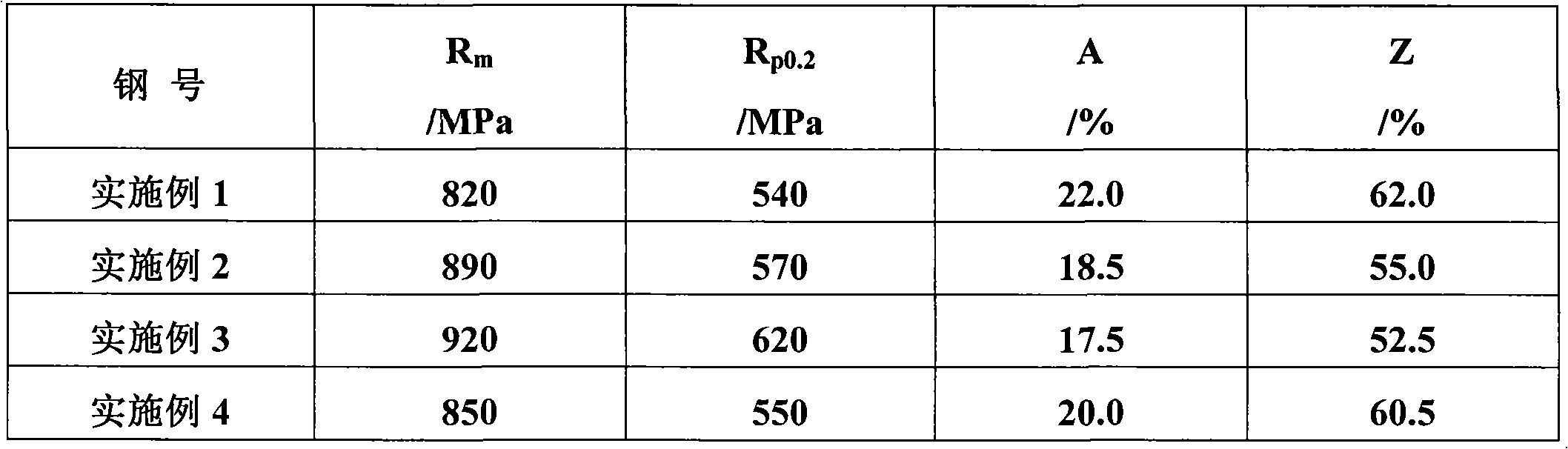

Embodiment 1~4

[0037] Table 3 Mechanical properties of Examples 1 to 4 of the non-quenched and tempered bainite cold heading steel for fasteners of the present invention

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides non-hardened bainite cold heading steel for a fastener and a manufacturing method thereof. The cold heading steel comprises the following components by weight percent: 0.06-0.15% of C, 0.10-0.50% of Si, 1.90-2.60% of Mn, not more than 0.015% of P, not more than 0.015% of S, 0.001-0.004% of B, 0.01-0.03% of Ti, not more than 0.040% of Als, the balance of Ferrum and unavoidable trace impurities. The manufacturing method comprises the following steps: (1) smelting in a converter or an electric furnace, externally refining, continuously casting into a steel billet, and then rolling into wires through a controlled rolling and cooling process by a wire rolling mill; spinning the wires, and rapidly cooling the spun wires at the front section of a roller way transport line by a forced cooling mode, wherein the cooling speed is 250 DEG C / min-500 DEG C / min; and (3) after steel wire rods are rapidly cooled to 540-600 DEG C, immediately transiting to the rear section of the roller way transport line for slow cooling by a heat insulating shield, wherein the cooling speed is 30 DEG C / min-120 DEG C / min. The invention can simplify processing production of the 10.9-grade fastener, improve production efficiency, lower energy consumption and production cost, and reduce emission.

Description

Technical field: [0001] The invention relates to a non-quenched and tempered bainitic cold heading steel wire rod for fasteners, in particular to a non-quenched and tempered bainitic cold heading steel for 10.9 high-strength fasteners and a manufacturing method thereof. Background technique: [0002] Fasteners are one of the three basic mechanical components. Cold heading steel wire is the main raw material for making bolts, nuts, screws, rivets and other fasteners. For the production of high-strength fasteners, 40Cr, 35CrMo and other alloy structural steels can be used as materials, and quenched and tempered heat treatment is carried out after deep processing. Its production process: raw material inspection → spheroidizing annealing → pickling → phosphating treatment → primary drawing → annealing → pickling → phosphating treatment → secondary drawing → cold heading → wire rolling → quenching, tempering (quenching and tempering treatment ) → electroplating → product perfor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/14C22C33/04C21D8/00

Inventor 章静阎军曹杰沈晓辉

Owner ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com