Single cylinder two-stroke internal-combustion engine with crank circular slide block

A two-stroke internal combustion engine, crank round slider technology, applied in the direction of cylinder, cylinder head, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

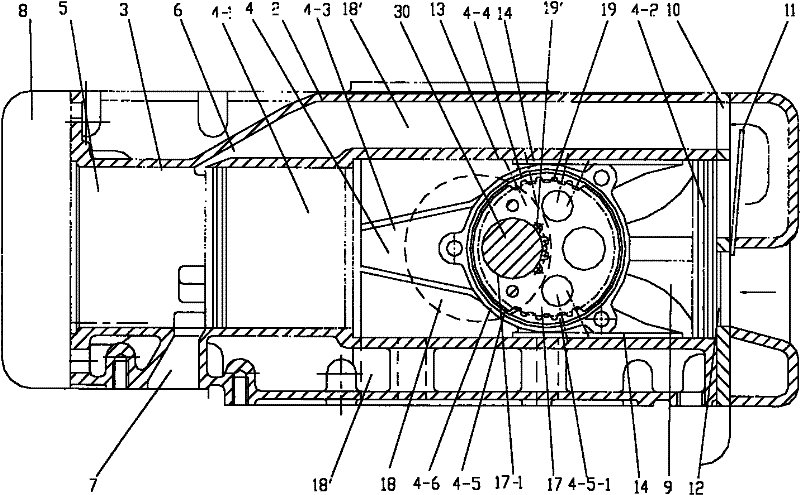

[0032] figure 1 A cross-sectional view of the main structure of the single-cylinder two-stroke internal combustion engine with crank and slider provided by the embodiment of the present invention.

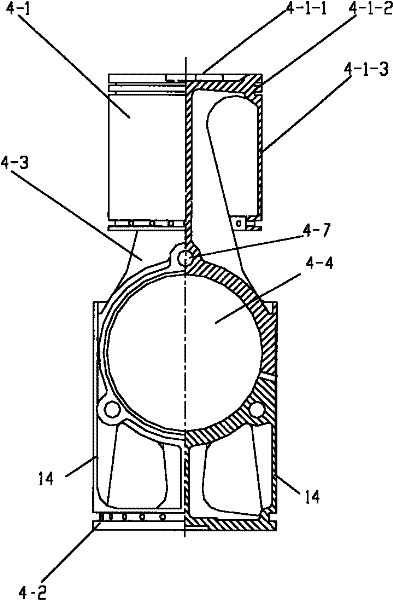

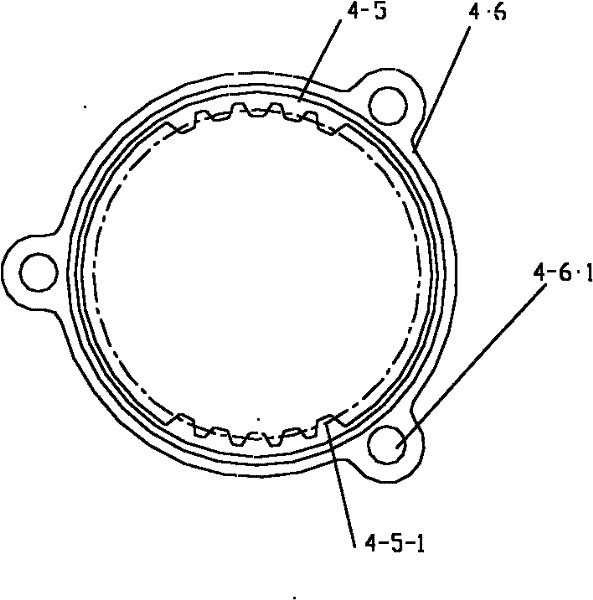

[0033] Such as figure 1 As shown, the crank-slider single-cylinder two-stroke internal combustion engine is provided with a cylindrical cylinder block 2, and the cylinder block 2 constitutes the main part of the casing of the internal combustion engine. A stepped cylinder 3 is arranged in the cylinder block 2, and the stepped cylinder 3 is divided into two sections with different bore diameters in the axial direction. Cooperating with the stepped cylinder 3, a differential piston 4 is provided, and the differential piston 4 is a double-acting piston with working heads at both ends. Wherein, the first working head 4-1 is a piston head of an internal combustion engine, and the piston head cooperates with the small-diameter section of the stepped cylinder 3. The entire range of mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com