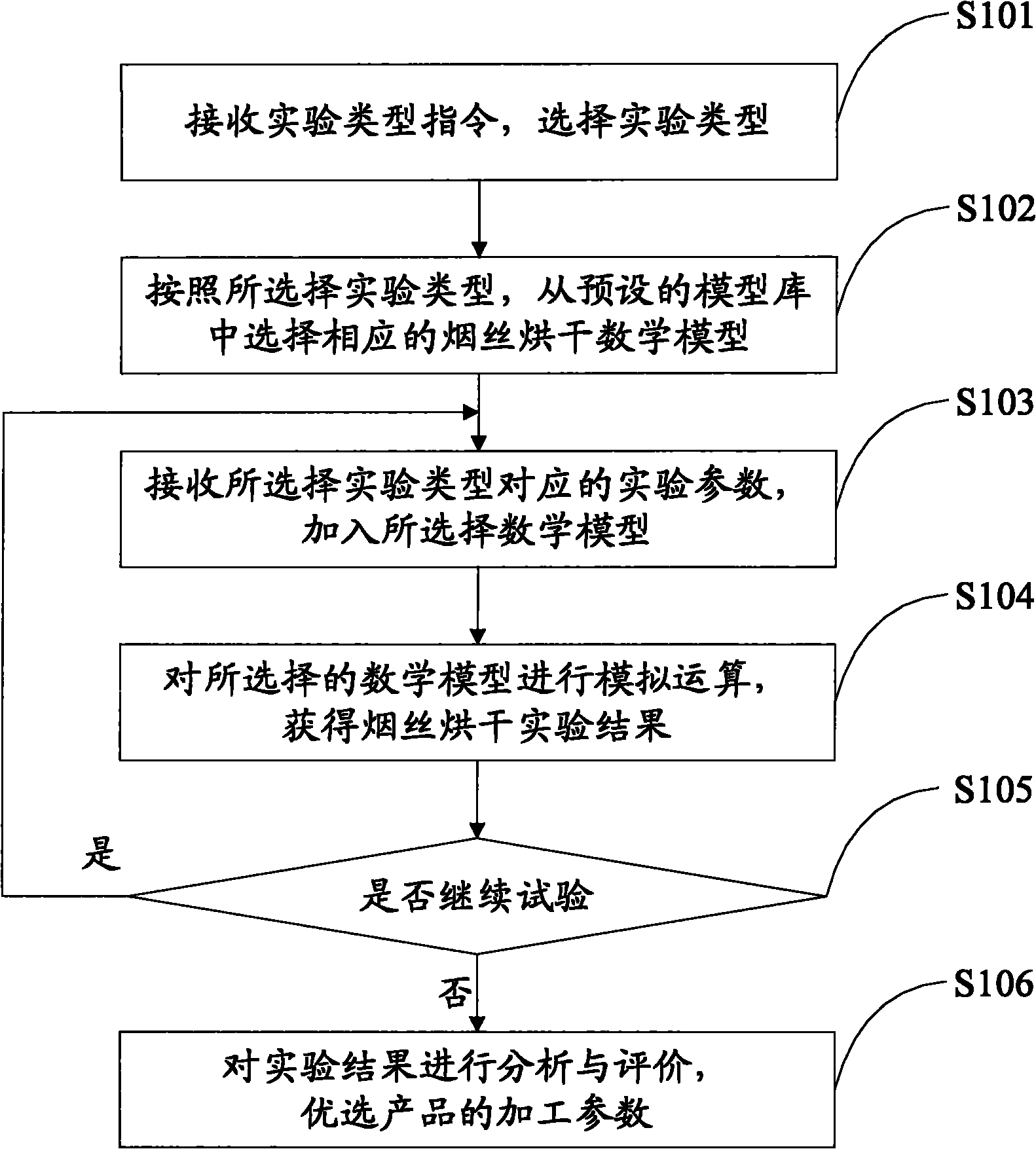

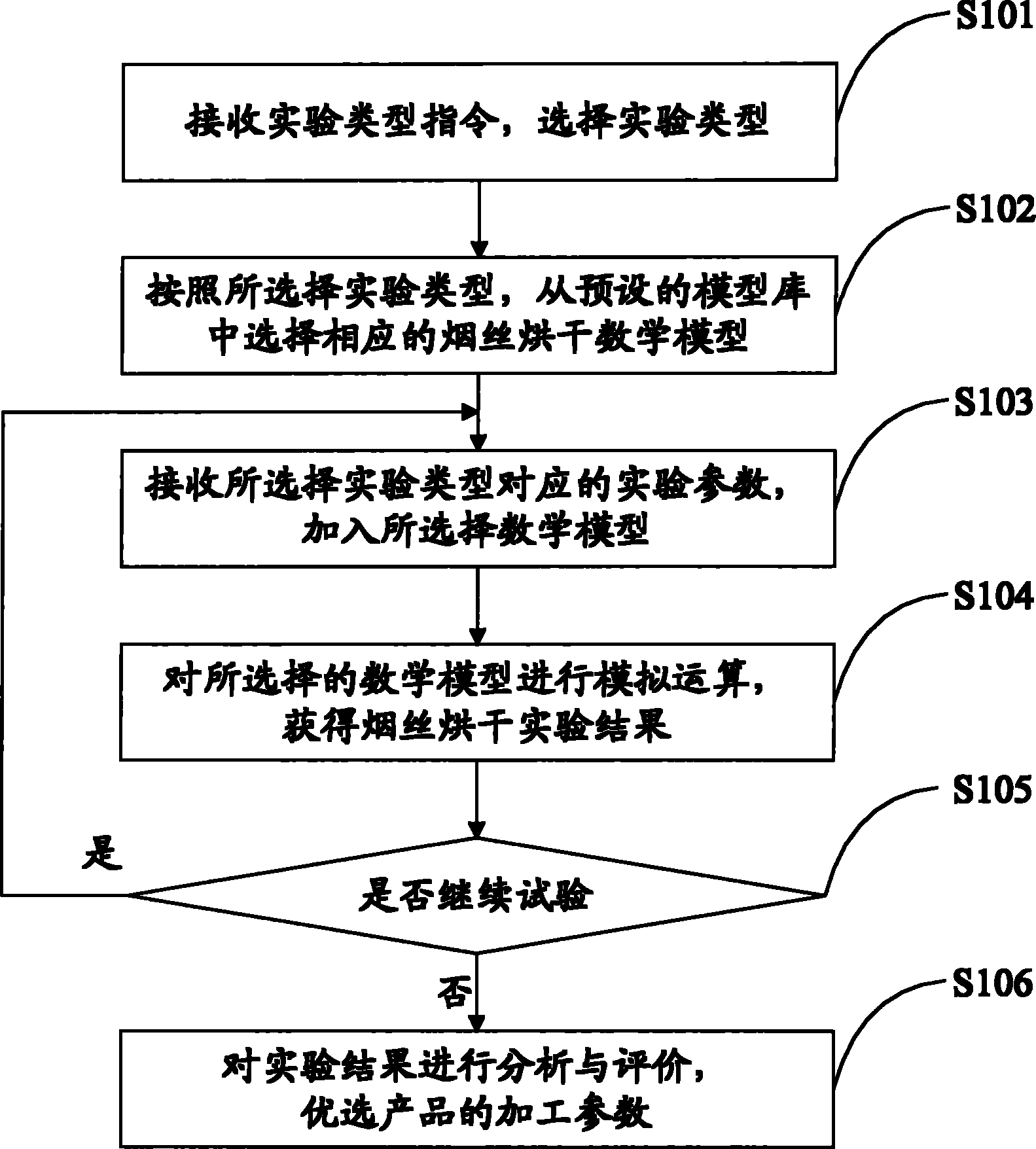

Shredded tobacco baking experiment method

An experimental method and shredded tobacco technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unfavorable competitiveness, difficult testing, and difficulty in obtaining all data, so as to improve market competitiveness and save production costs , The effect of speeding up the development process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] Example 1. Airflow drying method

[0042] Airflow tube drying is used in the drying and separation of powder and granular materials. At present, the airflow drying equipment used in the domestic tobacco industry mainly includes the HXD high-temperature airflow leaf shred dryer from Dickinson legg and the HDT superheated steam dryer from HAUNI in Germany. In this way, in addition to establishing the aerodynamic model and the geometric model of the airflow drying equipment, the following factors can be further considered:

[0043] The heat transfer of the airflow dryer is mainly due to convective heat transfer between the airflow in the airflow dryer and the shredded tobacco, so the convective heat transfer equation needs to be introduced;

[0044] For the mass transfer of the airflow dryer, it is necessary to introduce the mass transfer process model between the airflow in the airflow dryer and the shredded tobacco;

[0045] The droplet evaporation model needs to be int...

example 2

[0063] Example 2, drum drying method

[0064] Compared with airflow drying, drum drying has the advantages of high heat energy utilization efficiency, stable drying quality of products, and less aroma loss of products. However, the airflow movement in this drying equipment is difficult to test on-site, and the mathematical model that needs to be established for this purpose is:

[0065] Firstly, the airflow continuity equation, momentum equation and energy equation are introduced; secondly, according to the actual size of the drum drying equipment, the geometric model of the drum drying is established, including the drum (including the hot air pipe, the exhaust pipe, the inlet and the outlet) ) geometric model, the geometric model of the copy board inside the drum, etc.;

[0066] Thirdly, the geometric model is divided into grids, and the topological grid system of the geometric space model is established;

[0067] Finally, the process parameters of the drying equipment are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com