Low-concentration photovoltaic component

A photovoltaic module and concentrating system technology, applied in the field of solar photovoltaic power generation, can solve the problems of rising operating temperature of series resistance loss devices, decrease of open circuit voltage and conversion efficiency, increase of series resistance loss, etc., so as to reduce heat dissipation difficulty and heat dissipation. cost, high cell conversion efficiency, and large cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

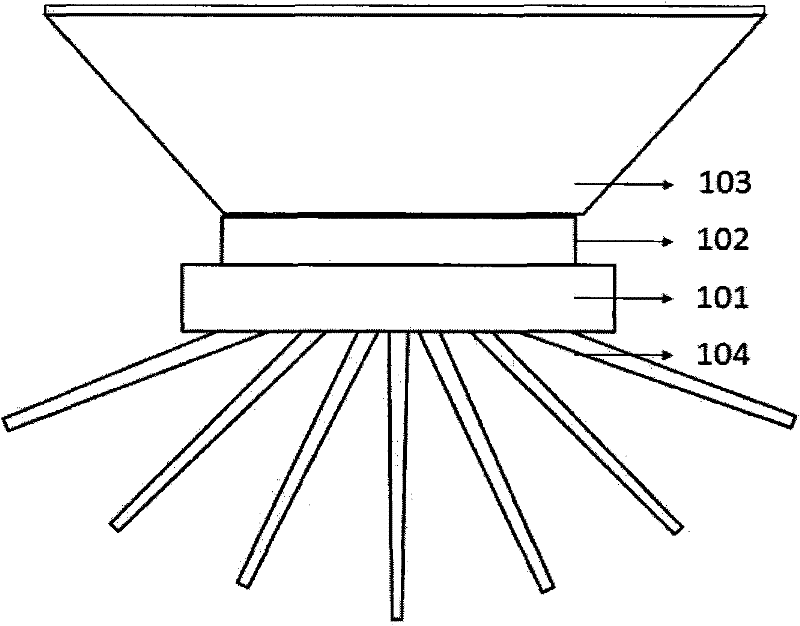

[0028] Such as figure 1 The low-magnification concentrating photovoltaic module shown includes a backplane 101 , a light receiver 102 , a concentrating system 103 and a heat sink 104 .

[0029]The backplane 101 is composed of an aluminum alloy substrate, epoxy resin doped with heat-conducting particles, and copper foil, wherein the copper foil is pasted on the aluminum alloy substrate through epoxy resin. Copper foil, epoxy resin, and aluminum alloy substrate are all good conductors of heat, which can conduct the heat on the copper foil to the aluminum alloy substrate in time, and conduct it to the radiator 104 connected to the base of the backplane 101 through the aluminum alloy substrate. The battery is cooled to prevent the conversion efficiency from decreasing or even causing accidents due to the high temperature of the photoreceiver during operation. The heat sink 104 is composed of a plurality of cooling fins.

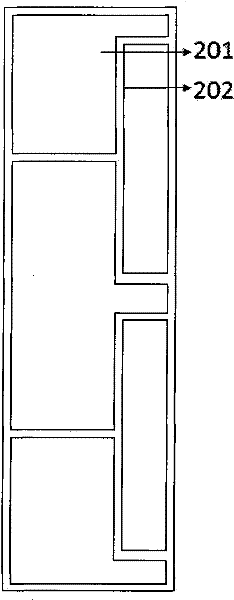

[0030] Such as figure 2 As shown, the copper foil inclu...

Embodiment 2

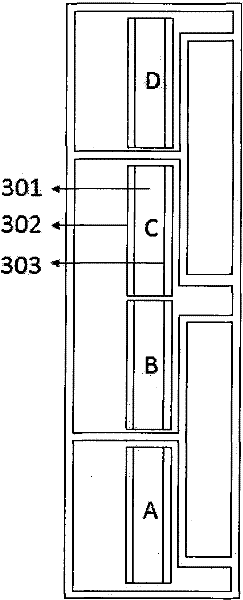

[0036] It is exactly the same as Embodiment 1, except that the positive and negative electrodes of the solar cell chips 301 (A, B, C, D) are set differently:

[0037] A: Left negative and right positive, B: Left positive and right negative, C: Left negative and right positive, D: Left positive and right negative, the effects are exactly the same.

[0038] Correspondingly, the connection methods between the solar cell chips 301 are also different: the negative electrode of A is connected to the copper foil area a, the positive electrode is connected to the copper foil area b; the negative electrode of B is connected to the copper foil b area, and the positive electrode is connected to the copper foil area b. Foil c-area connection; C’s negative pole is connected to copper foil c-area, positive pole is connected to copper foil d-area, D’s negative pole is connected to copper foil d-area, positive pole is connected to copper foil e-area...and so on, still forming a series connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com