Preparation method of plasticizing agent with thixotropy for unshaped refractory

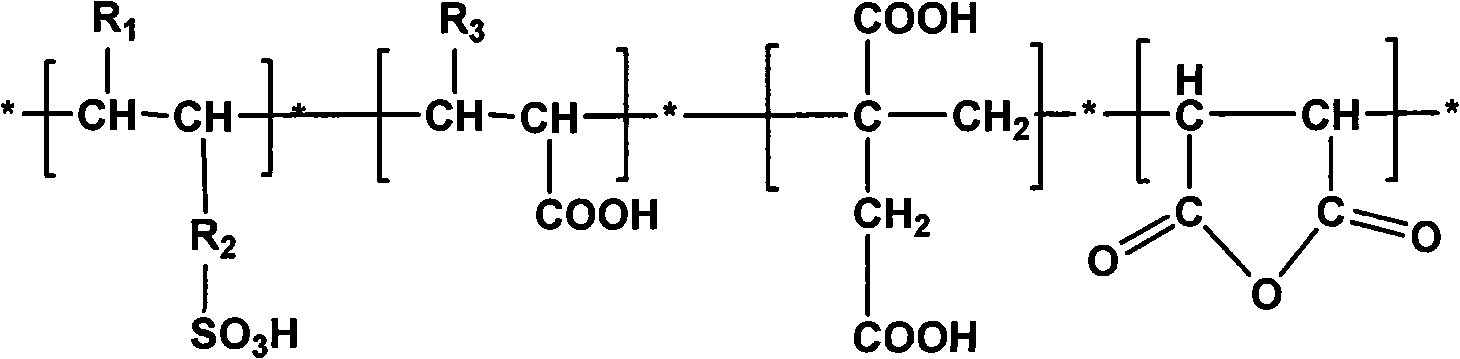

A technology of refractory material and plasticizer, which is applied in the field of refractory material admixture to achieve the effects of good fluidity, excellent high temperature mechanical properties and high thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

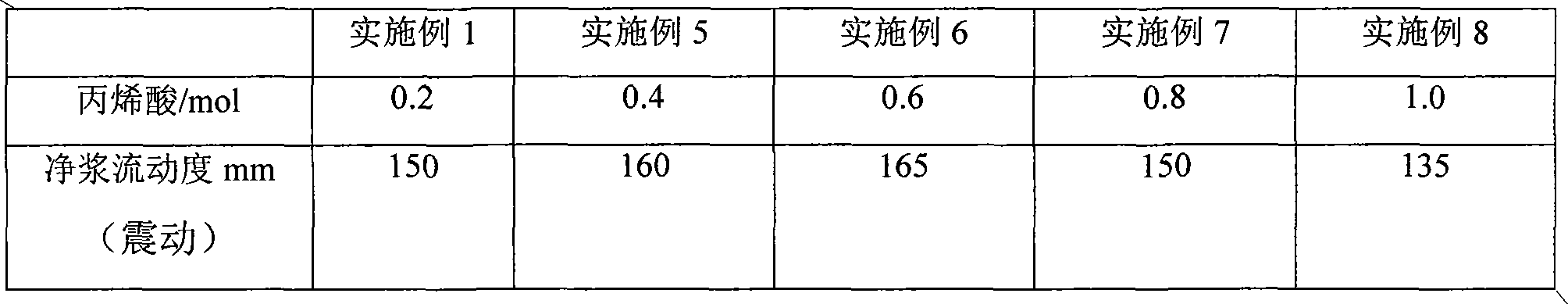

Embodiment 1

[0025]Weigh 41.4g (0.2mol) of 2-acrylamide-2-methylpropanesulfonic acid, 14.4g (0.2mol) of acrylic acid, and 19.6g (0.2mol) of maleic anhydride, all dissolved in 200ml of water, and add 1.9 g of ammonium persulfate at the same time g (2.5%), mercaptoethanol 3.80g (5%), after stirring evenly, get 1 / 5 and join in the three-necked reaction flask, keep the temperature in the bottle at 70°C, open the stirrer, and feed N 2 , reacted for about 30 minutes; the remaining 4 / 5 mixed solution was added dropwise within two hours. Raise the temperature to 90° C., add 0.5% initiator, react for another 4 hours, lower the temperature, neutralize the pH value to 9-10 with NaOH, and then spray dry to obtain a light yellow powder. The fluidity of the refractory micropowder system containing silica fume is determined to be 150mm (vibration).

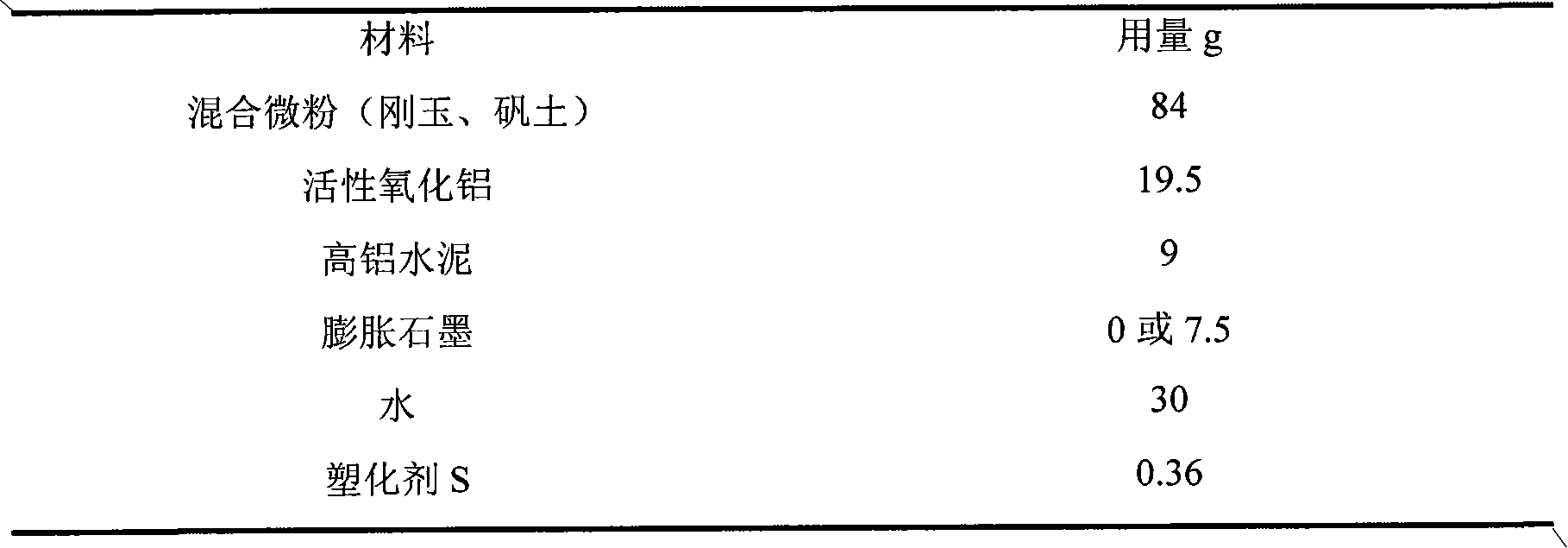

[0026] The main composition of the silica fume-containing monolithic refractory used to test the fluidity of the slurry is shown in the table below.

[00...

Embodiment 2

[0029] Weigh 0.2 mol of sodium methacrylic acid, 0.5 mol of methacrylic acid, and 0.3 mol of itaconic anhydride and dissolve them in 200 ml of water, then add ammonium persulfate, which is 5.0% of the total weight of the monomer, and 2% of mercaptoethanol, and stir evenly Finally, take 1 / 5 and add it to the three-necked reaction bottle, keep the temperature in the bottle at 60°C, turn on the stirrer, and feed N 2 , reacted for about 30 minutes; the remaining 4 / 5 mixed solution was added dropwise within two hours. Raise the temperature to 80° C., add 0.5% initiator, and react for another 6 hours. After cooling down, use NaOH to neutralize the pH value to 9-10, and then spray dry to obtain a light yellow powder. The fluidity of the clean slurry of the silica fume-containing refractory micropowder system is measured to be 140mm (vibration).

Embodiment 3

[0031] Take by weighing 0.2 mol of sodium propylene sulfonate, 1.0 mol of acrylic acid, 0.3 mol of itaconic acid, and 0.6 mol of maleic anhydride are all dissolved in 200 ml of water, then add ammonium persulfate weight to be 9% of the total monomer weight, 10% of mercaptoethanol, After stirring evenly, take 1 / 5 and add it to the three-necked reaction bottle, keep the temperature in the bottle at 70°C, turn on the stirrer, and feed N 2 , reacted for about 30 minutes; the remaining 4 / 5 mixed solution was added dropwise within two hours. Raise the temperature to 90° C., add 0.5% initiator, and react for another 2 hours. The temperature is lowered with NaOH to neutralize the pH value to 9-10, and then spray-dried to obtain a light yellow powder. The fluidity of the clean slurry of the silica fume-containing refractory micropowder system is measured to be 130 mm (vibration).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap