Submicron copper-based running-in restorative and application thereof

A technology of submicron copper powder and repairing agent, applied in additives, lubricating compositions, petroleum industry and other directions, can solve the problems of toxic raw materials, engine damage, large self-friction resistance, etc., to improve the running-in quality, increase power output, The effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

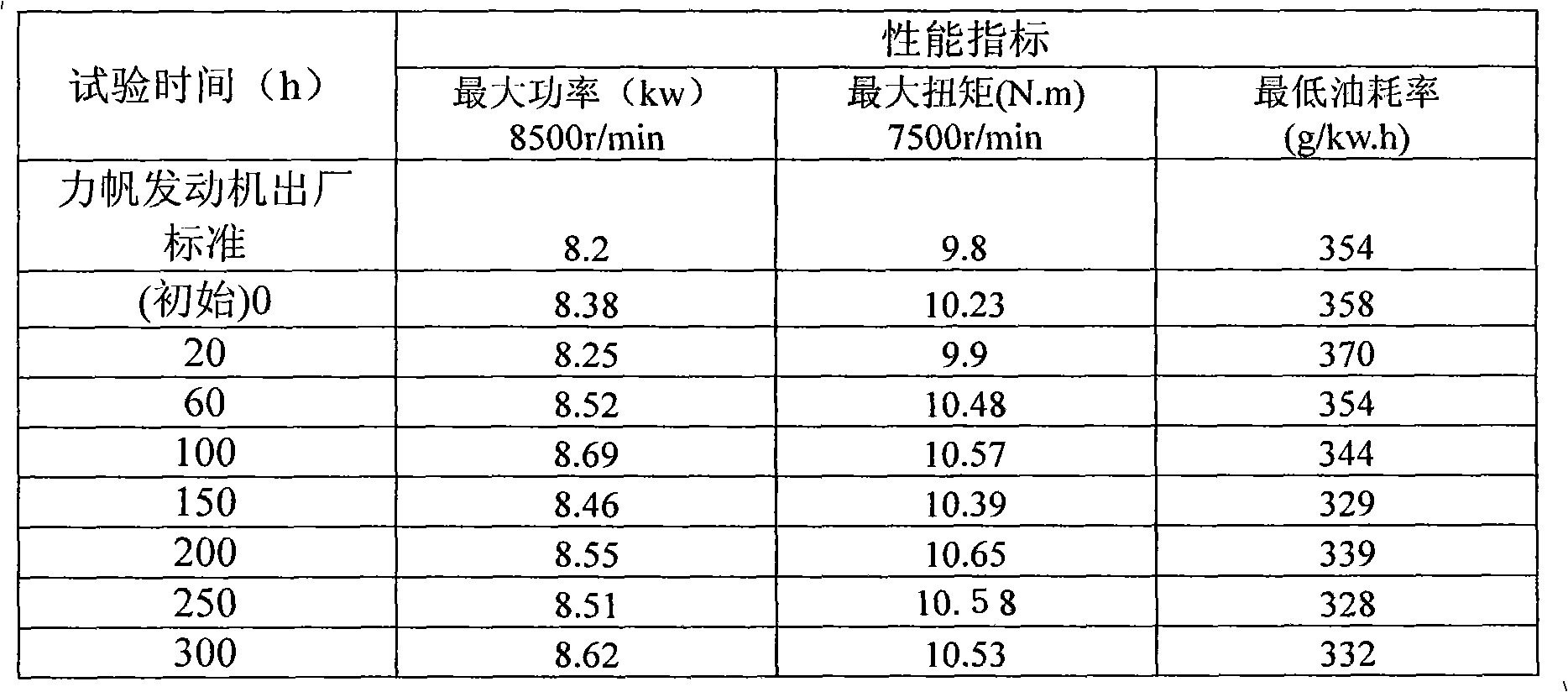

Image

Examples

Embodiment 1

[0041] Example 1 Preparation of submicron copper-based run-in repair agent

[0042] (1) Take 250 grams of submicron ultra-fine copper powder, add deionized water to make 2000 ml of slurry according to the concentration of 125g / L, stir and let it stand for 95 seconds by suspension method, take the above slurry and filter it with a 60-mesh copper sieve;

[0043] (2), with vacuum filtration, the soluble salt content wherein is repeatedly washed with deionized water, no white precipitate is separated out to checking with the barium chloride solution of 50g / L, confirms that sulfate ion is no longer contained;

[0044] (3), the filter cake is repeatedly beaten with 2000ml of absolute ethanol and vacuum filtered five times to replace the moisture contained therein so that the moisture content in the filter cake is lower than 1.0%;

[0045] (4), beating with absolute ethanol, configure according to the concentration of 125g / L, the slurry volume is 2000ml;

[0046] (5) Under stirring,...

Embodiment 2

[0050] Example 2 Preparation of copper-based run-in repair agent

[0051] (1) Take 150 grams of copper powder and add deionized water to make a slurry of 1000 ml. After standing for 120 seconds, take the upper slurry, and use the suspension method to separate the copper powder larger than 3 microns with a 60-mesh copper mesh filter;

[0052] (2), adopt vacuum filtration, the soluble salt content wherein is washed with deionized water, no white precipitate is separated out to checking with the barium chloride solution of 50g / L, determine to contain sulfate ion no longer;

[0053] (3), the filter cake is repeatedly vacuum-filtered five times with absolute ethanol 1500ml beating, and the moisture contained therein is replaced, so that the moisture content in the filter cake is lower than 1.0%;

[0054] (4), beating with dehydrated alcohol, make the concentration of copper powder in the slurry be 150g / L; The slurry volume is 1000ml;

[0055] (5), under stirring, control the tempe...

Embodiment 3

[0060] On June 10, 2010, a Santana 3000 produced in 2004 (running 210,000 kilometers, license plate number Yu A Z8785) was sent to the National Motor Vehicle Quality Supervision and Inspection Center (Chongqing) for engine performance testing. First conduct a blank test in accordance with relevant national standards, and the fuel consumption per 100 kilometers is 9.36 liters (Number 93 gasoline). On June 11, a 248ml bottle of the submicron copper-based running-in repair agent of the present invention was directly added to the lubricating oil tank (addition ratio 6.1%), and was directly mixed with the original engine oil that had been running for 2,500 kilometers, and then went directly to the southeast of Chongqing Dianjiang, Pengshui, Youyang and the surrounding areas of Chongqing carry out engine running-in repairs. On June 23, after 2100 kilometers of operation and running-in repair, it was sent to the testing center for testing according to national standards. The fuel con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com