Hydrogen closed circulation system used for fuel cell

A fuel cell and circulation system technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of large power consumption, explosion, and large self-consumption power, and achieve the improvement of hydrogen cycle utilization rate and service life The effect of improving self-consumption power is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

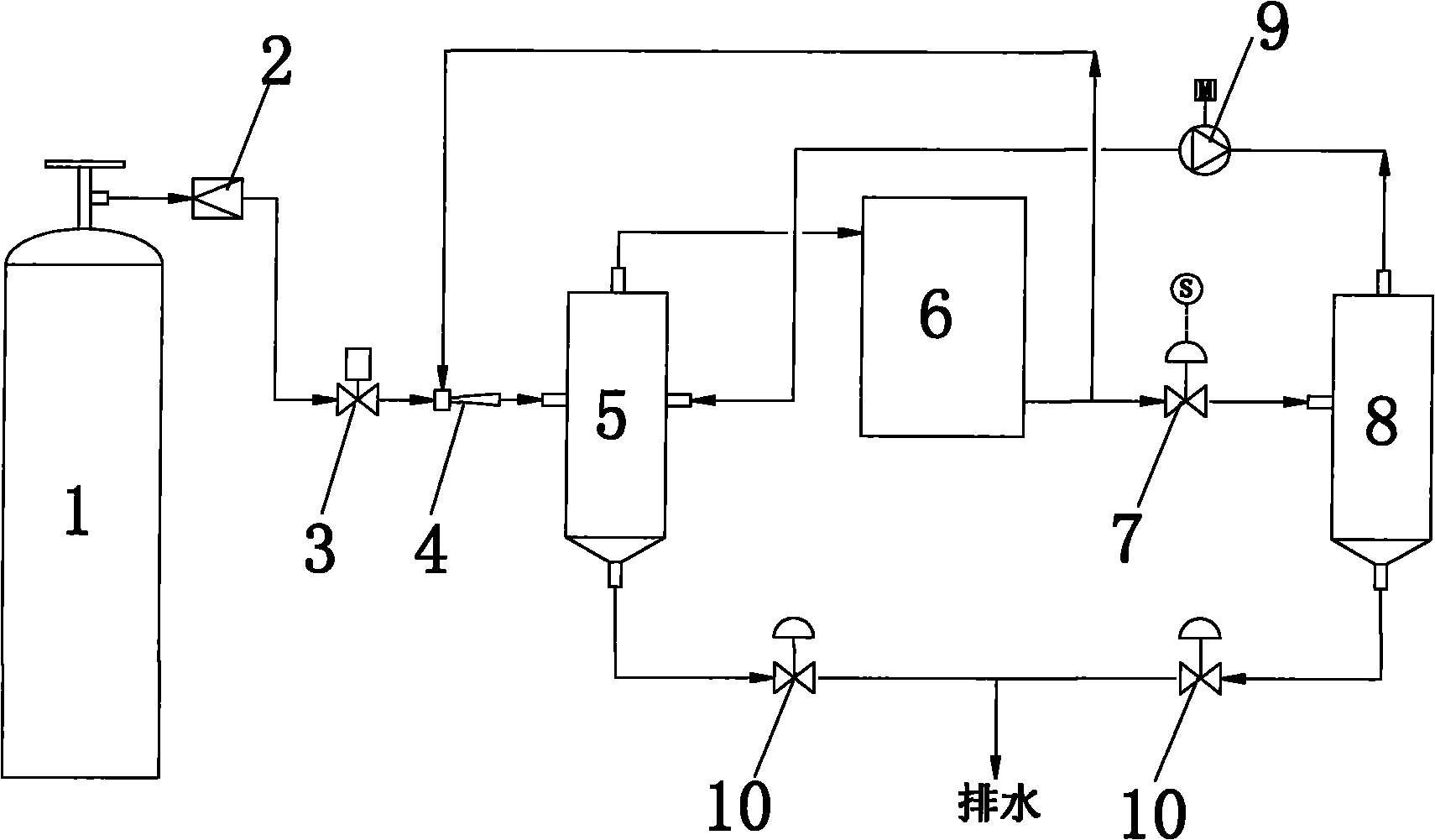

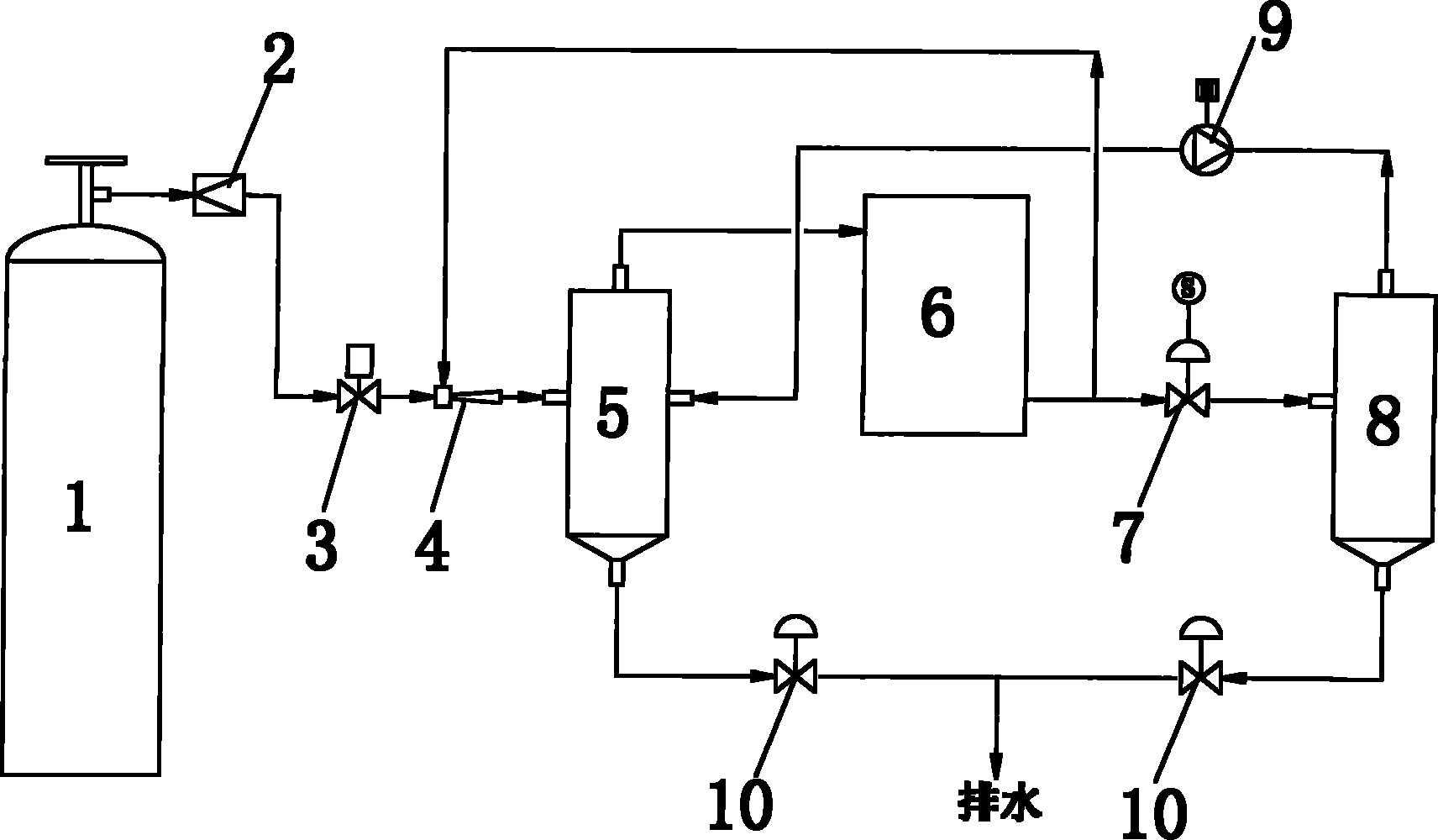

[0027] Such as figure 1 As shown, the hydrogen closed circulation system for 50KW fuel cell, the system includes hydrogen tank 1, pressure reducing valve 2, proportional switch solenoid valve 3, ejector pump 4, surge tank A5, fuel cell stack 6, hydrogen exhaust electromagnetic Valve 7, surge tank B8 and 200W diaphragm type hydrogen circulation pump 9, the hydrogen tank 1 is connected to the hydrogen inlet of the fuel cell stack 6 through the pressure reducing valve 2, the proportional switch solenoid valve 3, and the injection pump 4 in sequence, The hydrogen gas outlet of the fuel cell stack 6 is connected to the hydrogen exhaust solenoid valve 7, the surge tank A5 is arranged between the injection pump 4 and the hydrogen gas inlet of the fuel cell stack 6, and the pressure surge tank B8 is connected to the hydrogen exhaust solenoid valve 7. The hydrogen circulation pump 9 is respectively connected to the surge tank A5 and the surge tank B8. After the hydrogen comes out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com