Differential rotary cutting saw for cutting off circular tubes

A circular tube and sawing technology, which is applied in the field of high-speed cutting, can solve the problems of low production efficiency of milling saws, restricted production line speed, and high price of milling sawing discs, and achieves the effects of low sawing cost, low cost and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

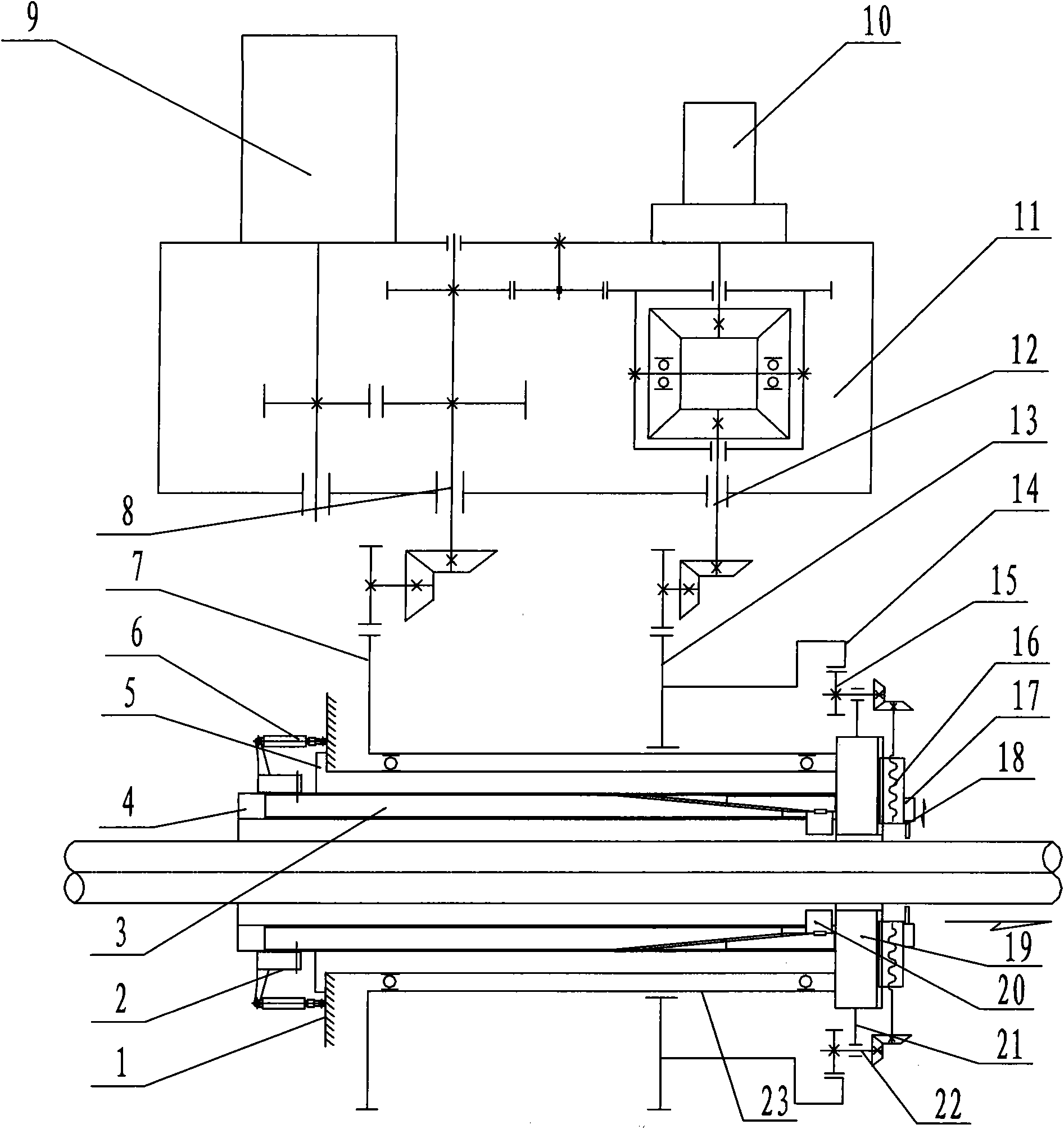

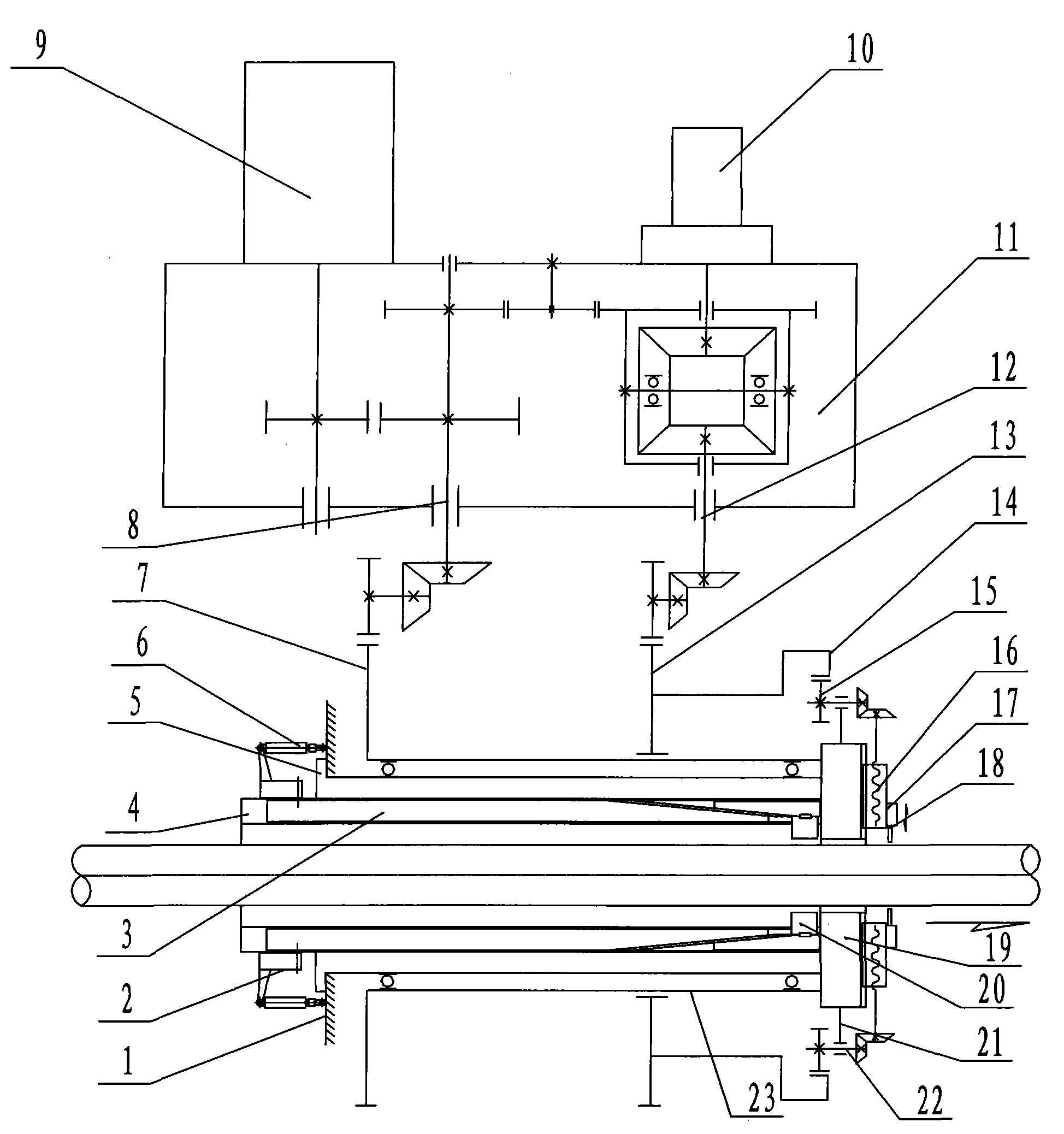

[0011] See figure 1 , A differential rotary saw for cutting round pipes, installed on a mobile trolley, can be used to cut the moving round pipe to length, fixed on the foundation, can cut off the stationary round pipe. The round pipe can be steel pipe, hard plastic pipe, etc.

[0012] The rotary saw includes a base 1, a support jacket 5 is fixedly connected to the base 1, and a tube clamping device is arranged in the support jacket 5; a rotating sleeve 23 is installed on the outer circle of the support jacket 5, one end of the rotating sleeve 23 In the inherent cutter head 19, four cutter holders 17 are slidably connected to the cutter head 19, each cutter holder 17 is connected with a cemented carbide cutting tool 18, and each cutter holder 17 is connected with a f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap