Special metal resistance rivet welding device

A technology of dissimilar metals and resistance, applied in the field of dissimilar metal resistance riveting welding devices, can solve the problems of inability to soften materials, and achieve the effects of avoiding riveting cracks and brittle cracks and reducing riveting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

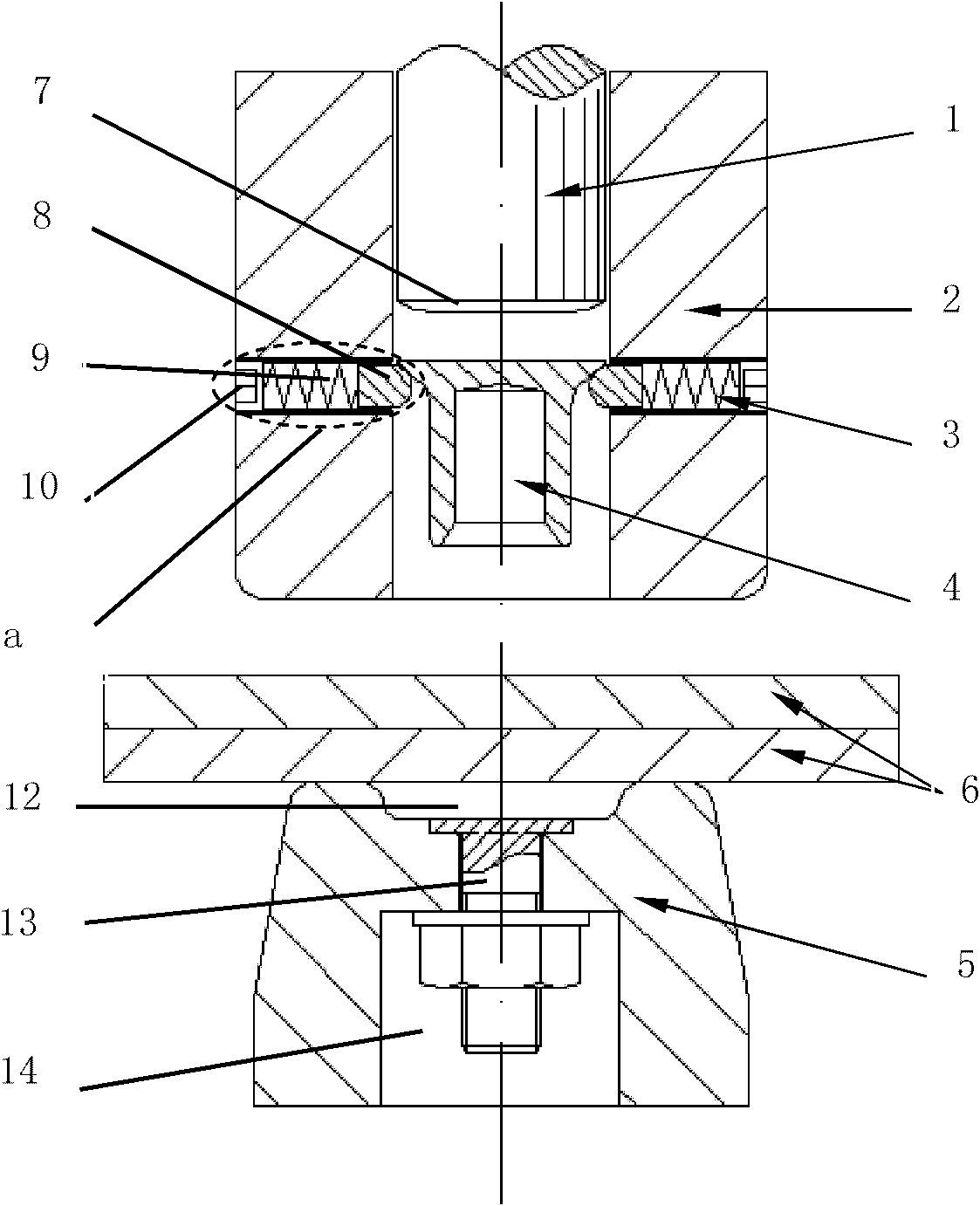

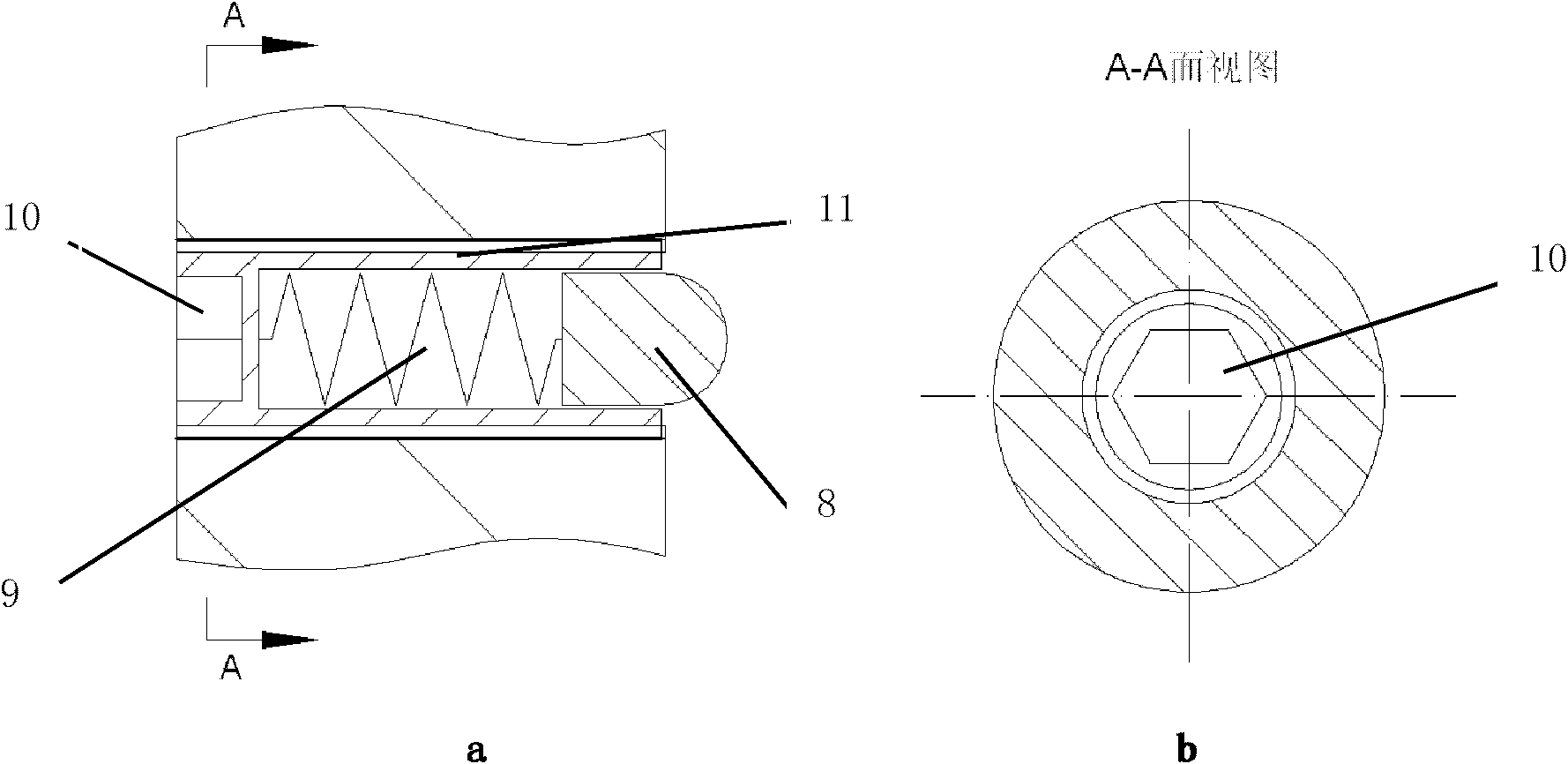

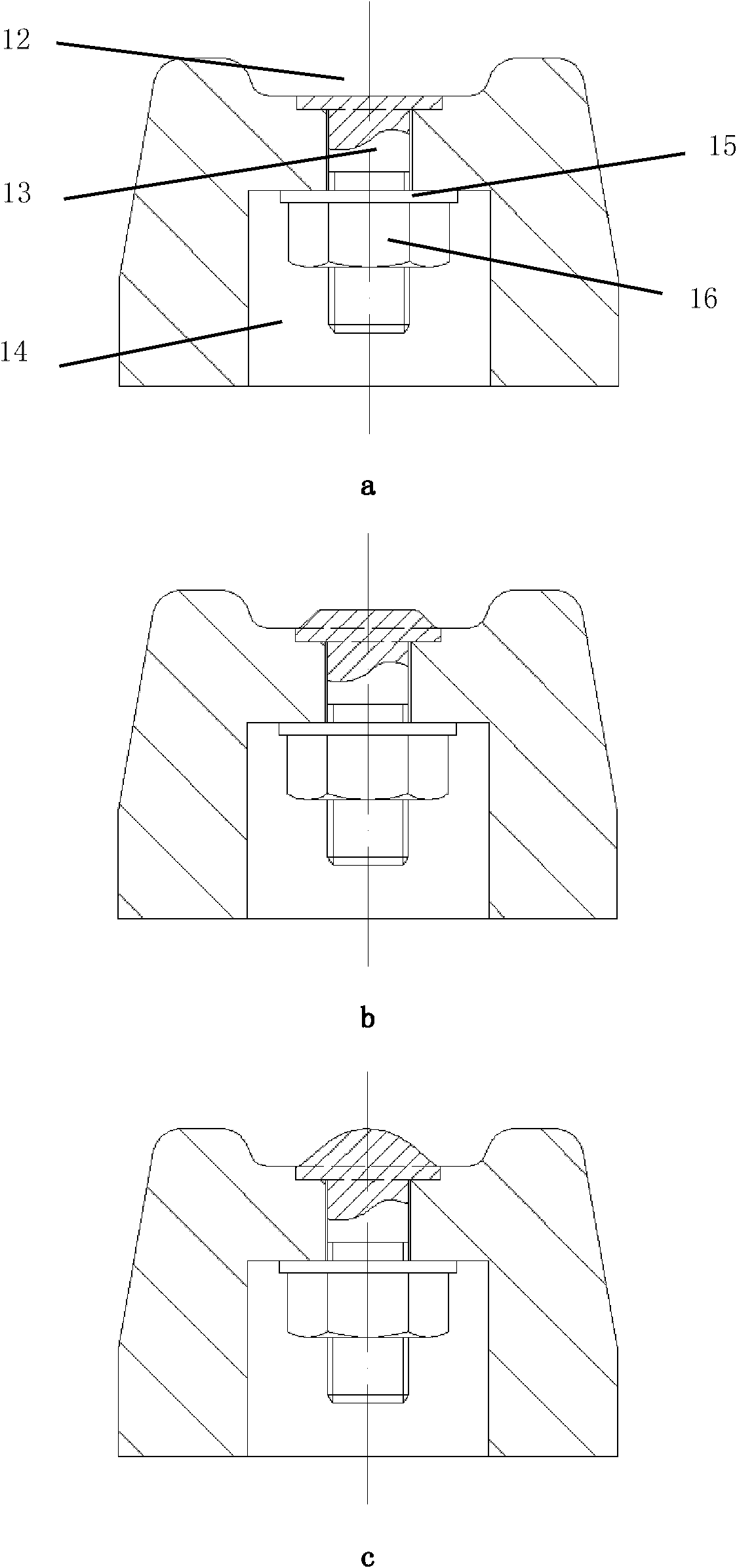

[0029] Such as figure 1 As shown, this embodiment includes: impact electrode 1, blank holder 2, spring bead positioning mechanism 3, semi-hollow rivet 4 and ring electrode 5, wherein: blank holder 2, plate to be welded 6 and ring electrode 5 are sequentially arranged from the top In the lower setting, the impact electrode 1 is sleeved in the blank holder 2, four spring bead positioning mechanisms 3 are distributed radially and horizontally in the blank holder 2, and the semi-tubular rivet 4 is vertically placed in the blank holder 2 and connected to the blank holder 2. The spring bead positioning mechanism 3 is in contact with each other, and the impact electrode 1, the semi-hollow rivet 4 and the ring electrode 5 are coaxially arranged.

[0030] A truncated cone 7 with an inclination angle of 10° is provided on the side of the bottom of the impact electrode 1 facing the semi-tubular rivet 4 to provide the current density required by the process.

[0031] The blank holder 2 i...

Embodiment 2

[0055] The plate 6 to be welded in this embodiment is: high-strength steel DP780 + aluminum alloy AA6061-T6, that is, the high-strength steel is on top and the aluminum alloy is on the bottom; the thickness of the plates is matched: 1.4mm+2mm.

[0056] The semi-hollow rivet 4 adopts the traditional self-piercing riveting countersunk head rivet, the head diameter is 7.8mm, the leg outer diameter is 5.3mm, and the rivet length is 7mm. The material is boron-treated high-strength steel, and the surface is coated with 12μm zinc-tin alloy plating.

[0057] Process parameters: the riveting speed of the impact electrode 1 is 40mm / s, the pre-pressing displacement is 1mm, the riveting current is 1.5kA DC, the brazing current is 5kA, the power-on time is 100ms, and the holding time is 40ms. The process curve is as follows Figure 5 (b) shown.

[0058] Other implementation modes of this embodiment are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com