Movable-electrode electro-osmosis dewatering device for dewatering urban sewage sludge

A mobile electrode and sludge dehydration technology, which is applied in dehydration/drying/concentrated sludge treatment, filtration separation, separation methods, etc., can solve the problems of reduced water content, high energy consumption, and difficulties in the application and promotion of sludge electroosmosis dehydration technology, etc. problem, to achieve uniform dehydration effect and maintain the effect of electroosmotic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

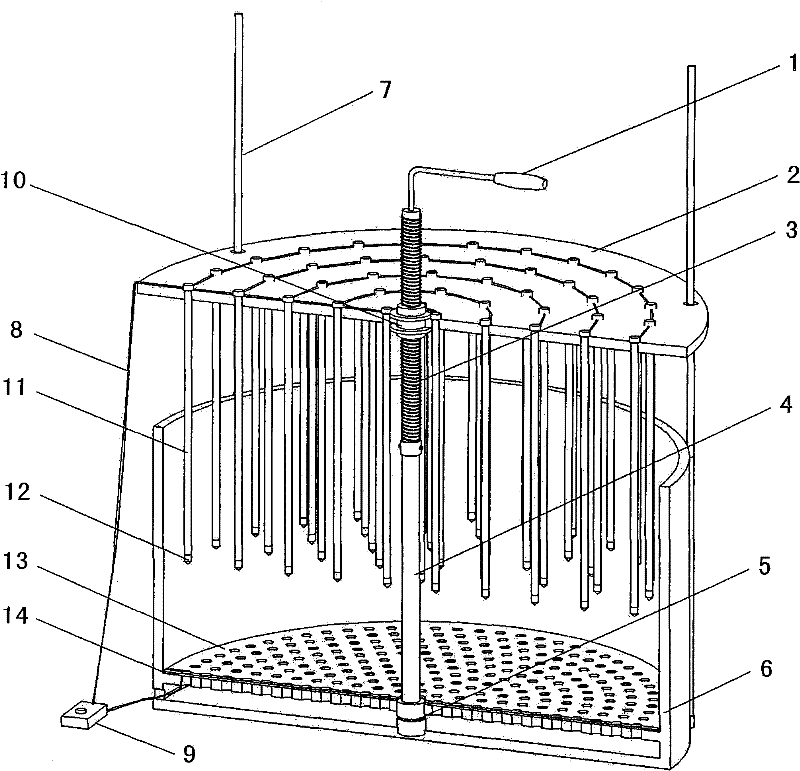

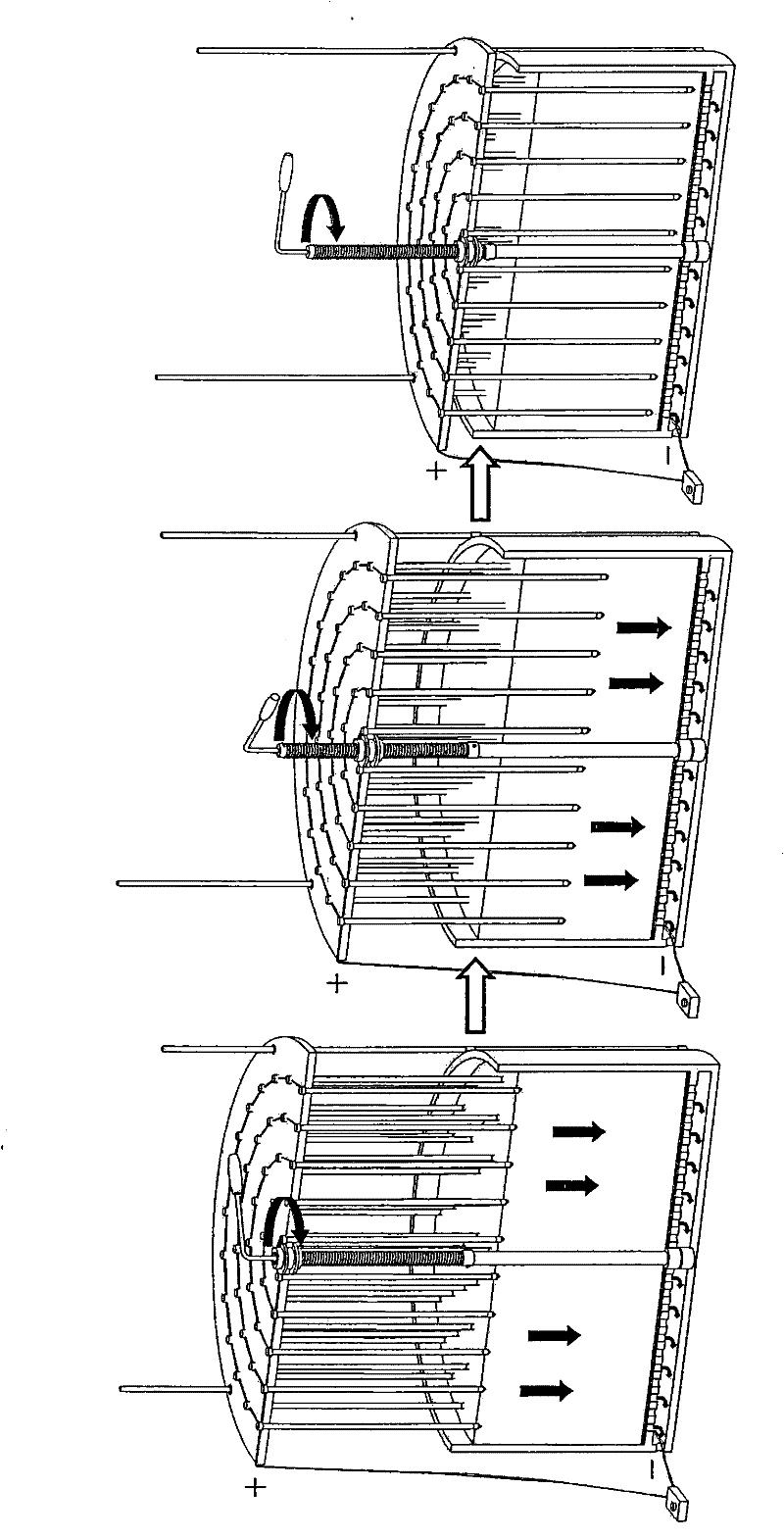

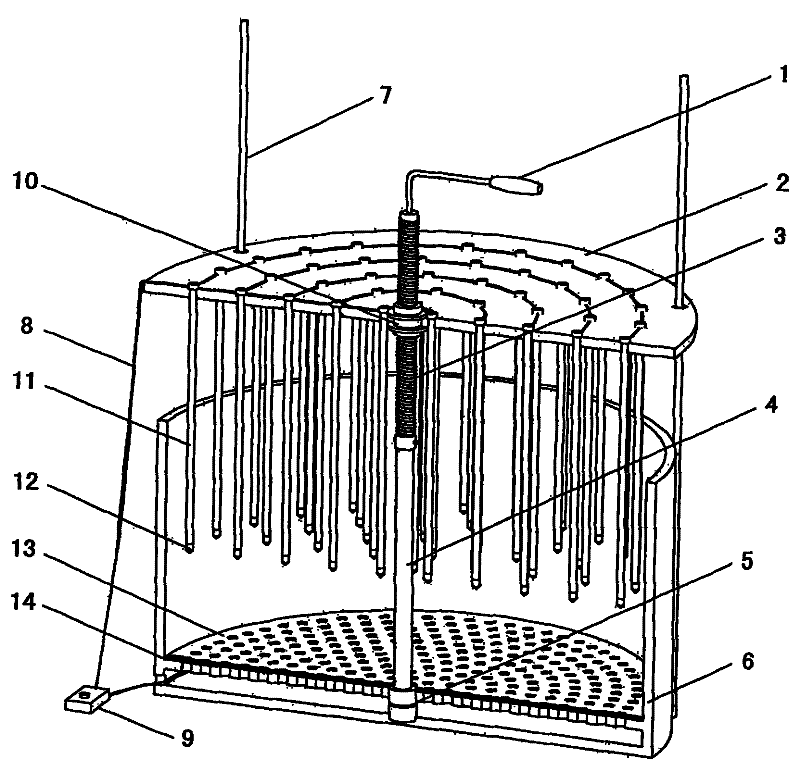

[0015] Such as figure 1 As shown, the present invention includes a screw rod 3 with a handle 1, a plexiglass upper plate 2, a plexiglass rod 4, a pvc sample loading cylinder 6 with an interlayer at the bottom, a plurality of support rods 7, an adjustable voltage DC power supply 9, A plurality of stainless steel conductive rods 11, a plurality of pointed alloy electrodes 12, an alloy fixed electrode plate 13 and a geotextile filter layer 14; the upper surface of the interlayer of the pvc sample loading cylinder 6 is sequentially covered with a geotextile filter layer from bottom to top 14 and the alloy fixed electrode plate 13, the upper surface of the interlayer of the pvc sample loading cylinder 6 and the alloy fixed electrode plate 13 are provided with through holes equally distributed, and the outer wall of the pvc sample loading cylinder 6 is equally divided into mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com