Method for extracting regenerated carbon-containing fused magnesia from waste magnesia carbon bricks

A technology for fused magnesia and waste magnesia-carbon bricks is applied in the field of recycling waste magnesia-carbon bricks. Etching performance, the effect of eliminating false particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

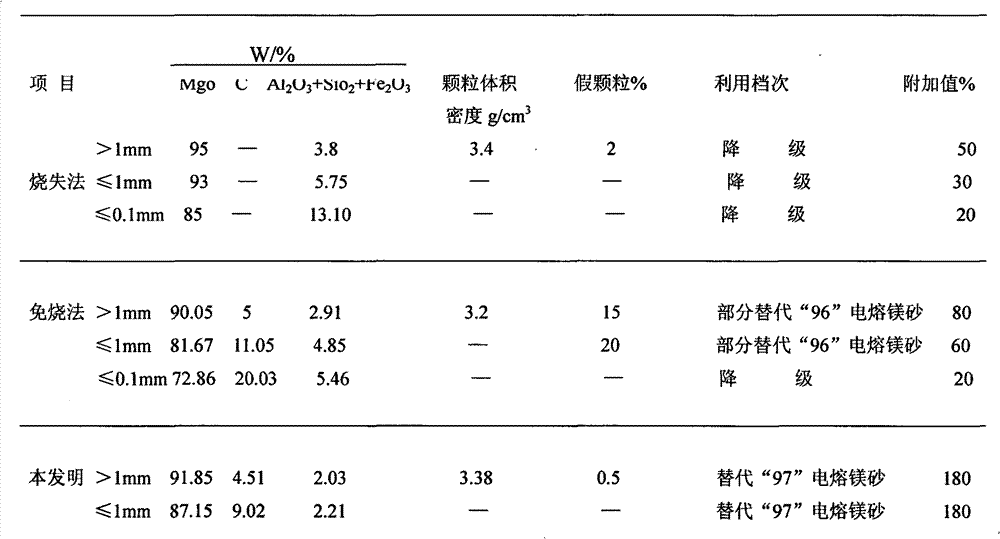

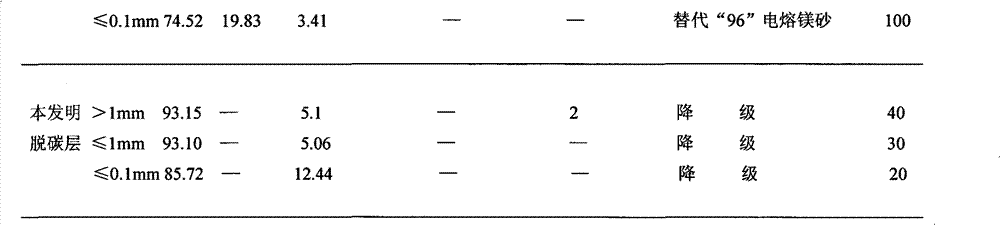

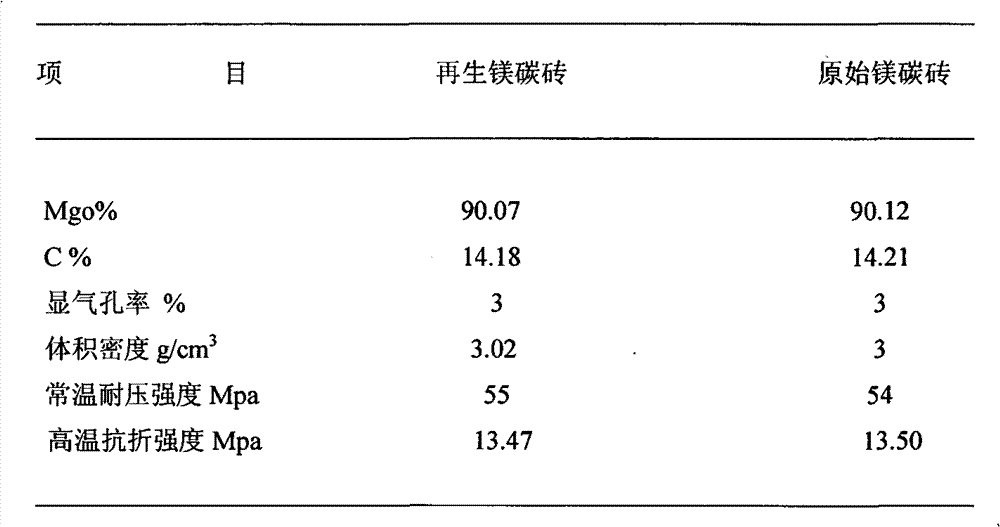

Examples

Embodiment 1

[0030] Remove the sundries on the surface of waste bricks and break them into pieces of about 150mm in size, with a volume of 30m 3 Calcined in the vertical kiln, the prepared fan model is 9-26 series, machine number is 8.0 NO High pressure centrifugal fan.

[0031]First, use about 150mm material blocks to install the cooling zone of the vertical kiln (accounting for about 1 / 3 of the kiln height), then in the calcination zone, use diesel to ignite, turn on the fan, and charge the material while blowing, and the temperature reaches 800 ℃-1000℃, graphite starts to oxidize, stop supplying fuel, rely on graphite oxidation in the material as fuel, charge at a speed of 90-110kg / min, fill the kiln at one time, and continue blasting for 80min-100min after loading, The temperature of the kiln in the calcining zone rises to 1350°C-1400°C, at this time, the flame is filled with the kiln roof, and the blast continues for 30-40 minutes. After the material is discharged, the second kiln i...

Embodiment 2

[0036] Remove the sundries on the surface of waste bricks and break them into pieces of about 150mm in size, with a volume of 30m 3 Calcined in the vertical kiln, the prepared fan model is 9-26 series, machine number is 8.0 NO High pressure centrifugal fan.

[0037] First, use about 150mm material blocks to install the cooling zone of the vertical kiln (accounting for about 1 / 3 of the kiln height), then in the calcination zone, use diesel to ignite, turn on the fan, and charge the material while blowing, and the temperature reaches 800 ℃-1000℃, the graphite starts to oxidize, stop supplying fuel, rely on the graphite oxidation in the material as fuel, charge the material at a speed of 100kg / min, and fill the kiln at one time. The temperature of the kiln rises to 1350°C-1400°C. At this time, the flame fills the kiln roof, and the blasting continues for 35 minutes. When the kiln temperature in the calcination zone drops to 600°C-650°C, the blasting is stopped, and the cooling z...

Embodiment 3

[0039] Remove the sundries on the surface of waste bricks and break them into pieces of about 150mm in size, with a volume of 30m 3 Calcined in the vertical kiln, the prepared fan model is 9-26 series, machine number is 8.0 NO High pressure centrifugal fan.

[0040] First, use about 150mm material blocks to install the cooling zone of the vertical kiln (accounting for about 1 / 3 of the kiln height), then in the calcination zone, use diesel to ignite, turn on the fan, and charge the material while blowing, and the temperature reaches 800 ℃-1000℃, the graphite starts to oxidize, stop supplying fuel, rely on the graphite oxidation in the material as fuel, charge the material at a speed of 110kg / min, fill the kiln at one time, continue blasting for 100min after loading, and calcine in the belt The temperature of the kiln rises to 1350°C-1400°C. At this time, the flame fills the kiln roof, and the blasting continues for 40 minutes. When the kiln temperature in the calcination zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com