Process for producing pellet by mixing and processing hematite, siderite and vanadium titano-magnetite concentrate

A technology for vanadium ilmenite concentrate and pellets, which is applied in the field of mixed processing of red rhombohedral and vanadium ilmenite concentrates and pellet ore, can solve the problems of unfavorable environment, unusable ores stacking, etc., achieve high economic benefits, improve The effect of ore utilization and reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The process of mixing red water chestnut and vanadium-titanium-iron concentrate and processing pellets in this embodiment includes the following steps in sequence: sulfuric acid slag pretreatment, batching, mixing, pelletizing, screening, drying, preheating and roasting;

[0018] The specific surface area of sulfuric acid slag can reach more than 1301.7cm2 / g through single ball milling pretreatment of sulfuric acid slag; the increase of specific surface area of sulfuric acid slag has a favorable impact on the drop strength and compressive strength of green balls;

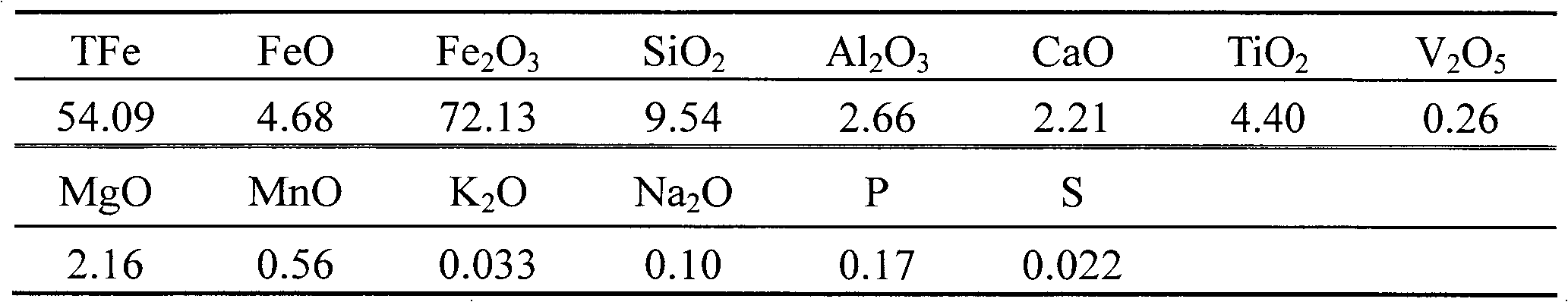

[0019] In the batching step, the reduction roasting magnetic separation process is used to process the mixed iron ore in Qijiang, Chongqing, and the iron ore concentrate grade is TFe56%, the phosphorus content is 0.21-0.35%, and the silicon dioxide content is 9.34-10.12%. As raw material Ⅰ, the iron ore concentrate grade of Taihe iron ore in Chongqing Iron and Steel Group is more than 56% TFe, the content ...

Embodiment 2

[0029] The process of mixing red water chestnut and vanadium-titanium-iron concentrate and processing pellets in this embodiment includes the following steps in sequence: batching, mixing, pelletizing, screening, drying, preheating and roasting;

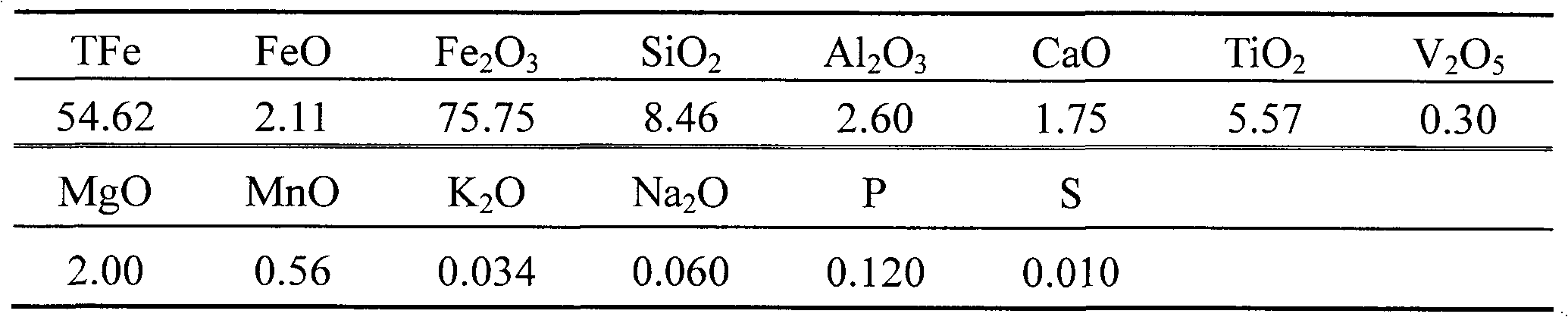

[0030] In the batching step, the reduction roasting magnetic separation process is used to process the mixed iron ore in Qijiang, Chongqing, and the iron ore concentrate grade is TFe56%, the phosphorus content is 0.21-0.35%, and the silicon dioxide content is 9.34-10.12%. As raw material Ⅰ, the iron ore concentrate grade of Taihe iron ore in Chongqing Iron and Steel Group is more than 56% TFe, the content of phosphorus is 0.015%, and the content of TiO 2 The vanadium-titanium ferroconcentrate with a content of 9.13% is used as raw material II, and 5 parts of raw material I, 4 parts of raw material II and 1 part of sulfuric acid slag are prepared by weight;

[0031] In the pelletizing step, pelletizing is carried out through the grate...

Embodiment 3

[0040] The mixed processing pelletizing process of chiling and vanadium-titanium iron concentrate in this embodiment includes the following steps in sequence: sulfuric acid slag pretreatment, batching, high-pressure roller mill pretreatment, mixing, pelletizing, screening, drying, and preheating and roasting;

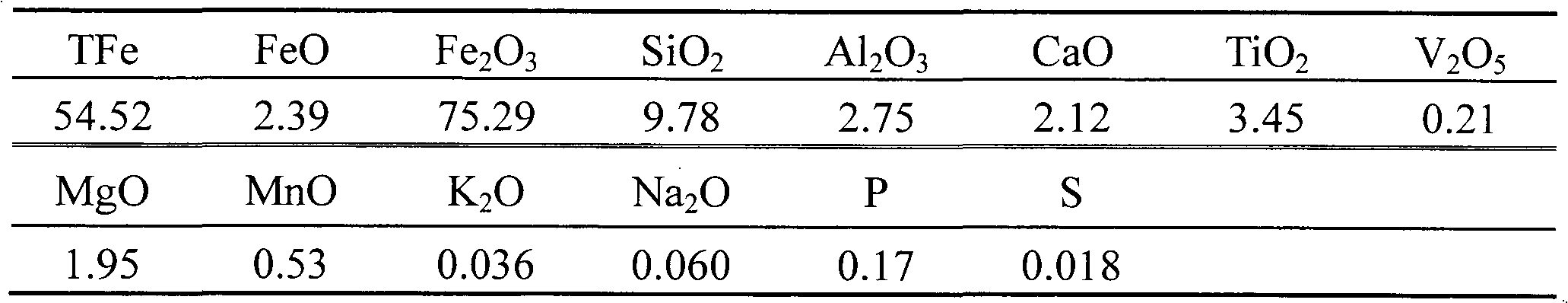

[0041]In the batching step, the reduction roasting magnetic separation process is used to process the mixed iron ore in Qijiang, Chongqing, and the iron ore concentrate grade is TFe56%, the phosphorus content is 0.21-0.35%, and the silicon dioxide content is 9.34-10.12%. As raw material Ⅰ, the iron ore concentrate grade of Taihe iron ore in Chongqing Iron and Steel Group is more than 56% TFe, the content of phosphorus is 0.015%, and the content of TiO 2 The vanadium-titanium ferroconcentrate with a content of 9.13% is used as raw material II, and 3 parts of raw material I, 5 parts of raw material II and 1 part of sulfuric acid slag are prepared by weight;

[0042] Thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com