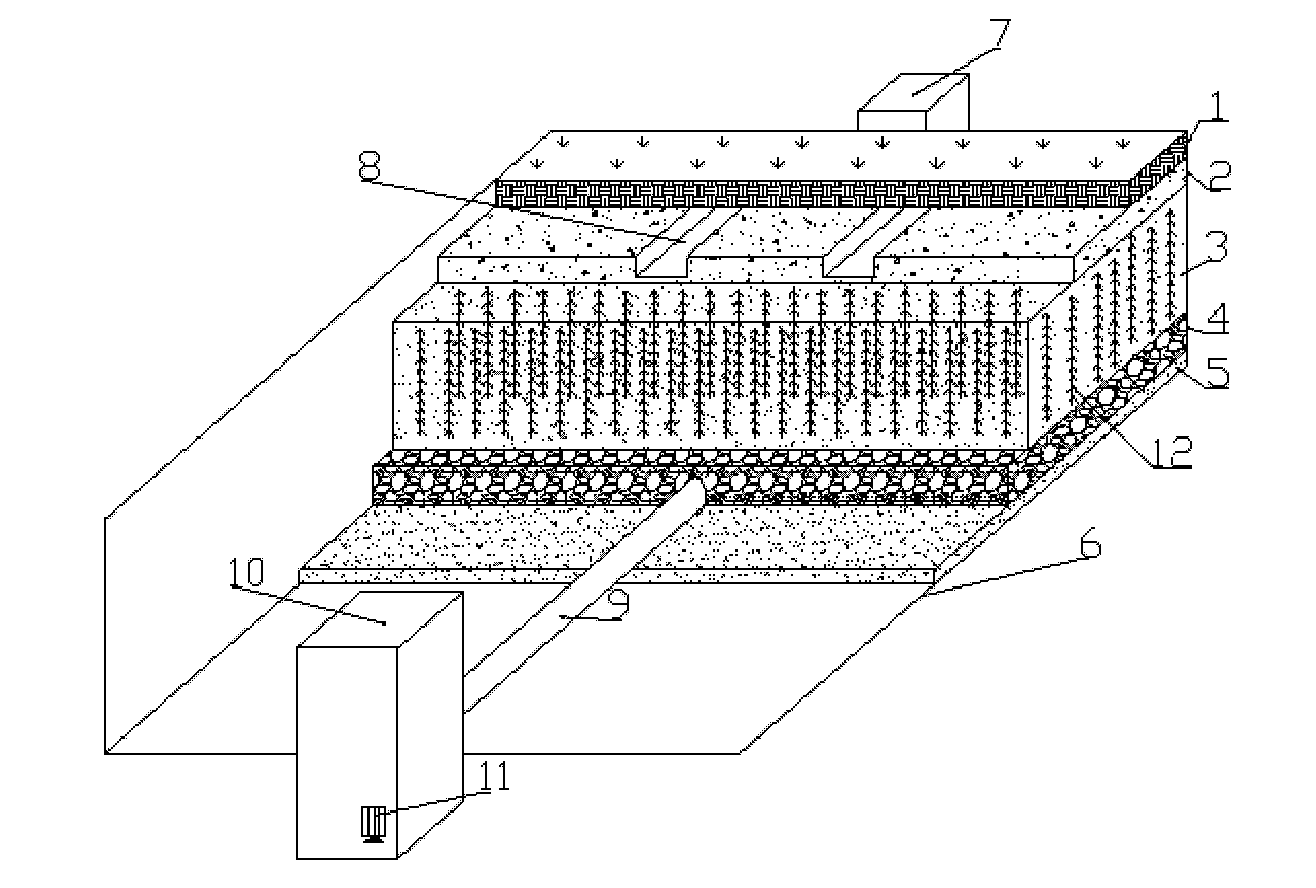

Onsite processing device for discarding initial rainwater in heavy rain without occupying area and processing method thereof

A technology for initial rainwater and treatment devices, applied in water supply devices, waterway systems, sewage removal, etc., can solve problems such as blockage, improve permeability, expand the geographical scope of use, and do not occupy the ground area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

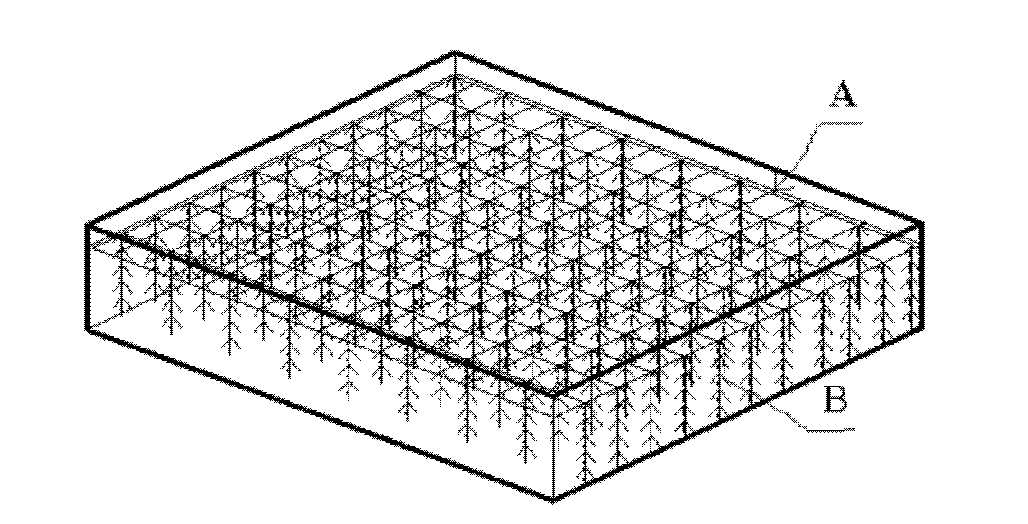

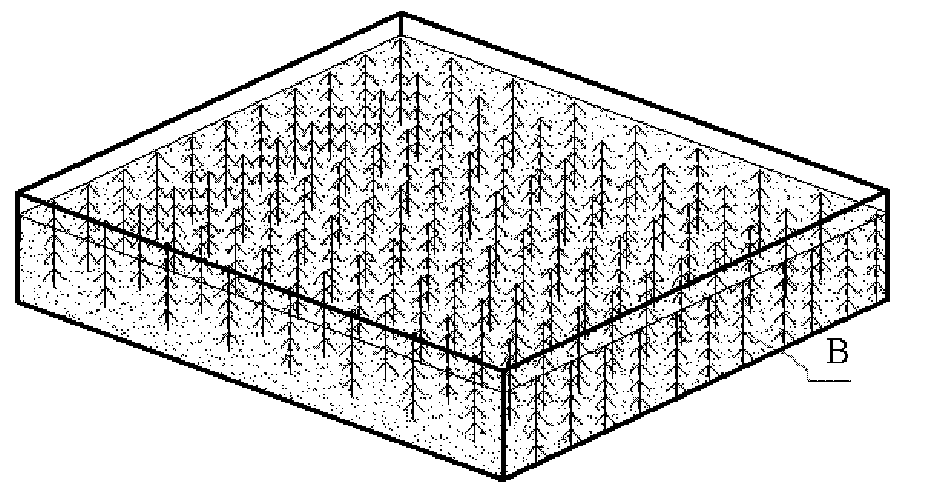

Method used

Image

Examples

Embodiment 1

[0042] The permeability coefficient in a community in Chongming County, Shanghai is taken as 6.2×10 -4 cm / s of soil, build a filling surface area of 10m per cubic meter of soil 2 The rainwater purification soil trench of biological filler, the depth of the trench is 700mm when the soil layer is not included, the depth of the trench after the soil is 800mm, and the area is 2.0m 2 , the design treatment water volume is 0.3-0.9m 3 / d, that is, the hydraulic load is 15-45cm / d. At the same time, a decontaminated soil trench of the same size without biofill was built as a comparison. Artificial water distribution, dosing into the test device for testing.

[0043] Influent COD Cr 50.4-180.6mg / L, SS 18-52mg / L, total phosphorus 1.9-2.7mg / L, ammonia nitrogen 13.4-38.7mg / L, pH 5.8-6.5, with a hydraulic load of 40cm / d After entering the test device and passing through the device, the COD of the effluent Cr SS is 11.1-27.8mg / L, SS is 5.5-7.1mg / L, total phosphorus is 0.05-0.06mg / L, ...

Embodiment 2

[0045] Taking the permeability coefficient of a university campus as 2.9×10 -7 cm / s of soil, build a filling surface area of 20m per cubic meter of soil 2 Initial rainwater waste stream purification process of biological filler. The depth of the trench is 700mm when the soil layer is not included, and the depth of the trench after the soil is 800mm, and the area is 2m 2 , the design treatment water volume is 0.4-0.8m 3 / d, that is, the hydraulic load is 20-40cm / d. At the same time, a domestic sewage purification soil ditch of the same size without biological filler was built as a comparison. Simulate the initial rainwater on the road surface, and put it into the test device for testing.

[0046] Water inflow simulated road surface runoff: COD is 186-312mg / L, SS is 25-106mg / L, total phosphorus is 0.4-1.3mg / L, ammonia nitrogen is 1.6-4.9mg / L, and total nitrogen is 2.3-7.4mg / L , with a pH of 5.3-6.5, was dosed into two soil trenches with a hydraulic load of 40cm / d, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com