Roof greening and overhead photovoltaic cell panel combined heat insulation system

A photovoltaic cell panel and roof greening technology, which is applied to roof insulation materials, roofs using tiles/slate tiles, roofs using flat/curved panels, etc. Space waste and other issues, to ensure healthy growth, small loss, and reduce noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

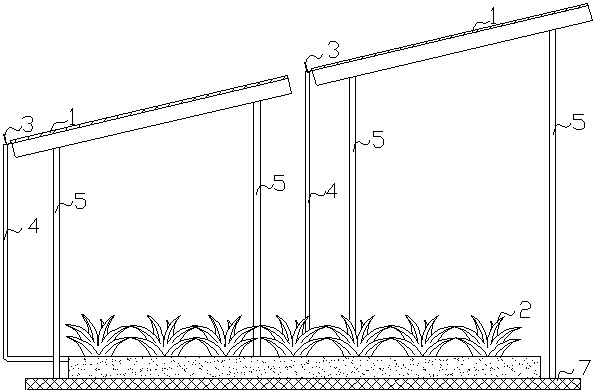

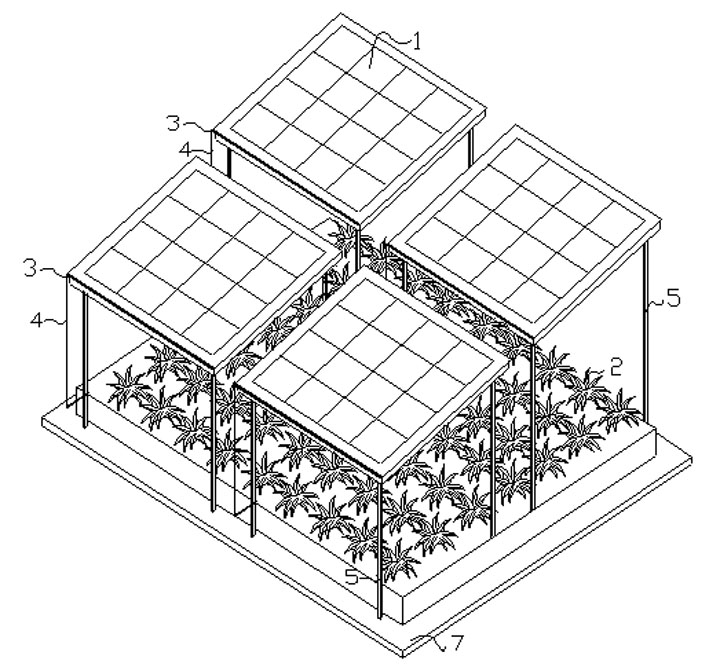

[0016] Embodiment one: if figure 1 , 3 Shown, the present invention comprises the greening vegetation layer 2 that is arranged on the roof 7, the photovoltaic battery panel group erected on the greening vegetation layer 2, the battery panel group includes a plurality of gaps arranged so that the greening vegetation layer 2 has batteries that leak light The plate 1 and the lower edge of the battery plate 1 are provided with a rainwater collection tank 3 , and the rainwater collection tank 3 is connected to the greening vegetation through the aqueduct 4 . The greening vegetation layer 2 is equipped with a maintenance drip irrigation device for adding water and an automatic control system for monitoring. The maintenance drip irrigation device and the automatic control system are electrically connected to the battery board 1, and the battery board is erected on the top of the greening vegetation layer 2 through the support frame 5. The greening vegetation layer 2 is the vegetatio...

Embodiment 2

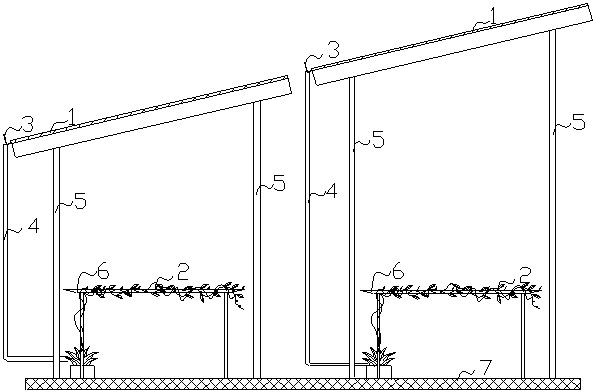

[0018] Such as figure 2 Shown, differ from embodiment one in that the greening vegetation layer 2 is a potted vegetation layer 2 placed on the roof 7, and the potted vegetation layer 2 can be a vine vegetation layer 2, and when it is a vine, the roof 7 and Between the battery panels 1, there is a support 6 for the climbing growth of vines to form an overhead heat insulation layer composed of green branches and leaves. The support 6 includes a vertical climbing frame that guides the vines to grow upwards and a climbing frame that supports the lateral growth of the vines. frame, thus forming an overhead green plant insulation layer.

[0019] The specific implementation steps are as Figure 4 Shown:

[0020] 1. Install shade-loving heat-insulating green plants on the roof 7, which can be soil-covered lawns, soil-covered shrubs, or potted vines and potted shrubs; 6. The plants will first grow towards the top of the support 6, and then grow horizontally along the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com