Lithium ion battery and positive plate thereof

A technology of lithium ion battery and positive electrode sheet, which is applied to non-aqueous electrolyte battery electrodes, secondary batteries, circuits, etc., can solve the problems of increased short-circuit point temperature, small short-circuit resistance, and potential safety hazards, so as to improve safety characteristics, increase The effect of large ohmic resistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

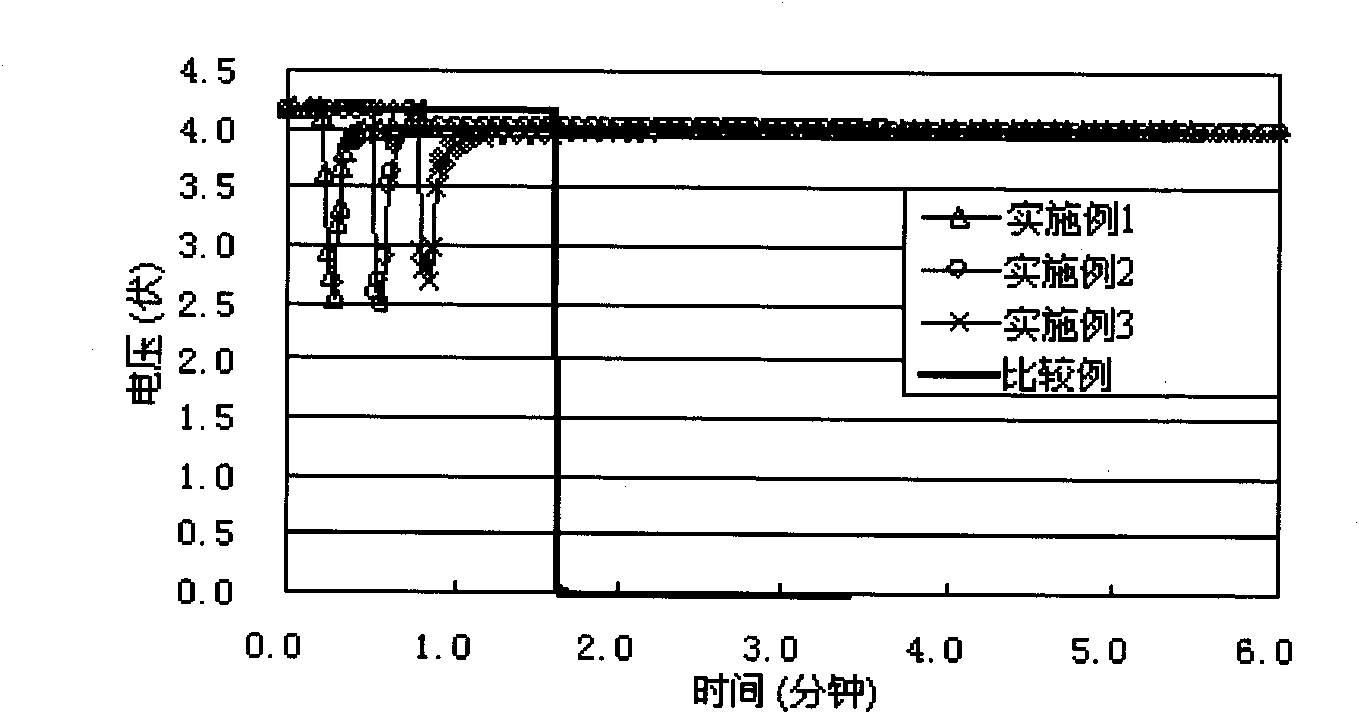

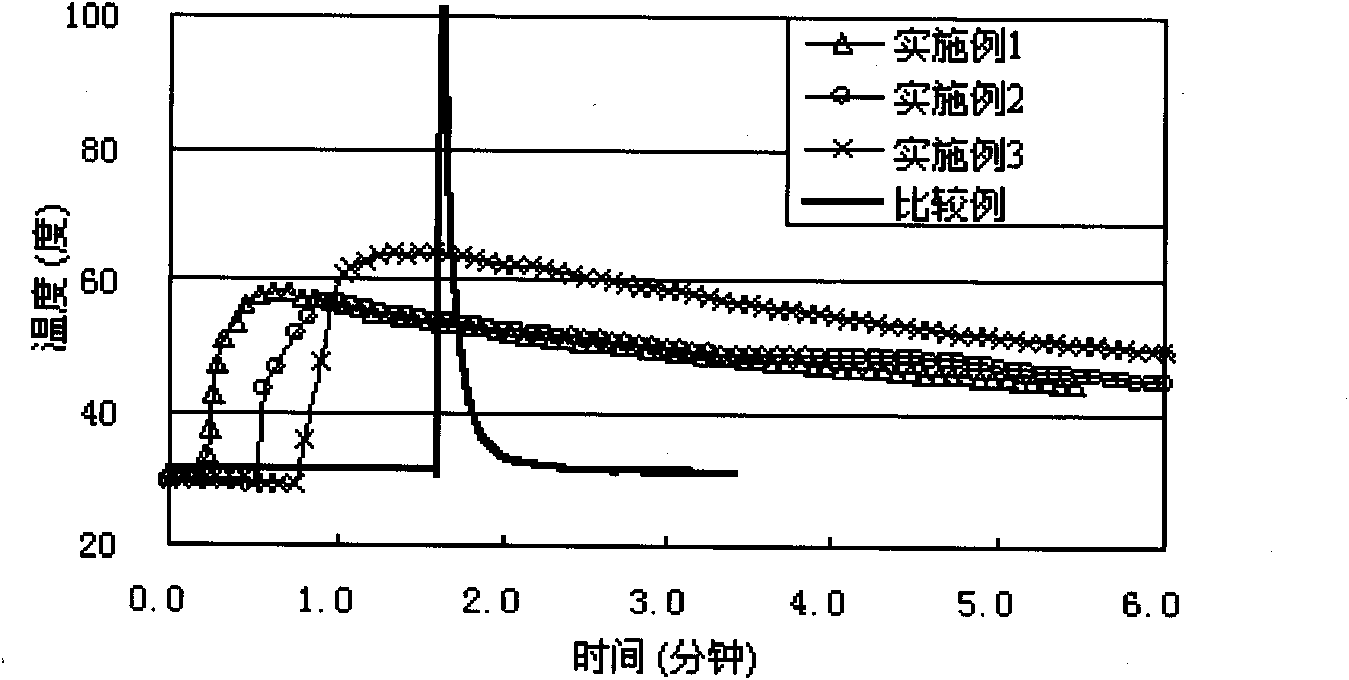

[0028] Example 1 The preparation of the lithium ion battery cathode sheet of the present invention is divided into two steps. The first step is to prepare the ordinary lithium ion battery cathode sheet: the positive electrode active material lithium cobaltate, the binder polyvinylidene fluoride (PVDF), and the conductive agent (Conductive carbon Super-P) is uniformly mixed in the dispersant N, N-dimethylpyrrolidone (NMP) to obtain a uniform and stable positive electrode slurry; then, the positive electrode slurry is evenly coated on the positive electrode current collector aluminum foil , after fully drying to obtain common lithium-ion battery positive sheet. The second step is to insulate and protect the positive electrode sheet obtained in the first step: first, dissolve the metal oxide particles and the binder styrene-butadiene rubber emulsion (SBR) in the dispersant water according to a certain weight ratio to obtain a uniform and stable The slurry; then, the slurry is cov...

Embodiment 2

[0029] Example 2 The preparation of the positive electrode sheet of the lithium-ion battery is also divided into two steps. The first step of preparing the positive electrode sheet of the ordinary lithium-ion battery is the same as that of Example 1, and will not be repeated here. The difference from Example 1 is that in the second step of Example 2, the exposed positive electrode current collector aluminum foil is protected by a polymer coating: first, the polymer powder (or emulsion) is mixed with a suitable solvent ( or dispersant) to obtain the corresponding solution (or dispersion); then, this solution (or dispersion) is covered by coating or dipping on the aluminum foil of the positive electrode collector exposed on the positive electrode sheet, and after drying, an insulating Positive electrode sheet protected by polymer coating. According to needs, the polymer can be selected from styrene-butadiene rubber, nitrile rubber, carboxylated nitrile rubber, carboxylated styre...

Embodiment 3

[0030] Example 3 The preparation of the positive electrode sheet of the lithium-ion battery is also divided into two steps. The first step of preparing the positive electrode sheet of the ordinary lithium-ion battery is the same as that of Example 1, and will not be repeated. The difference from Example 1 is that in the second step of Example 3, insulating adhesive tape is used to protect the exposed positive electrode current collector aluminum foil. Covering the exposed positive electrode collector aluminum foil on the positive electrode sheet with insulating tape can also achieve insulation protection for the exposed positive electrode current collector aluminum foil. Compared with Embodiment 1 and Embodiment 2 of the present invention, Embodiment 3 of the present invention is easier to implement.

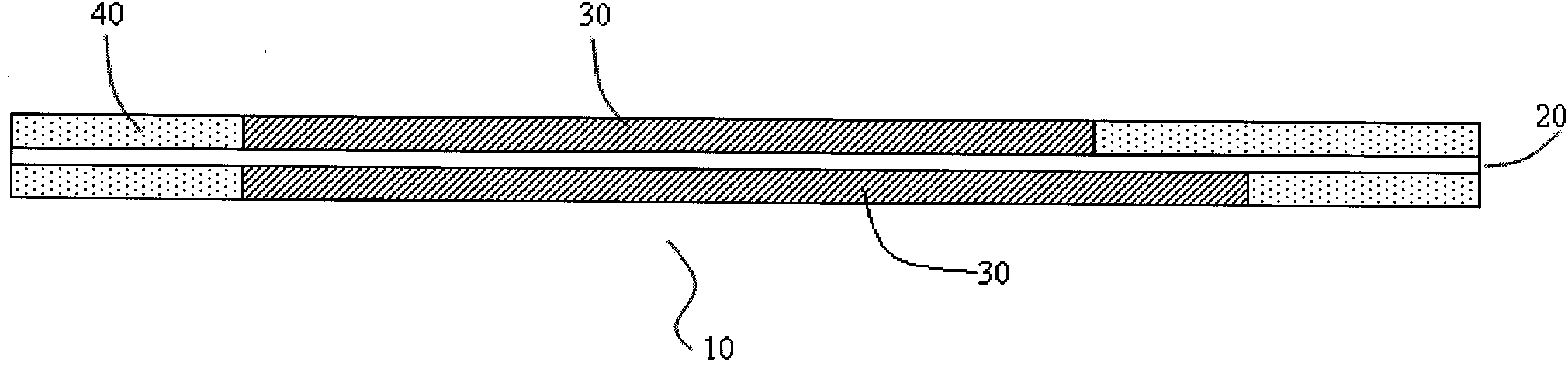

[0031] figure 1 Shown is a schematic structural view of the lithium-ion battery positive sheet 10 of the present invention obtained according to Examples 1 to 3 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com