Aromatization catalyst and preparation method thereof

A catalyst and aromatization technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of high dry gas yield and low yield of aromatics, and achieve low dry gas yield, Effect of high yield of aromatics and high yield of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Catalyst C of the present invention 1 The preparation method is as follows:

[0025] (1) Modification of ZSM-5 molecular sieve

[0026] Take 100 grams of SiO 2 / Al 2 o 3 HZSM-5 molecular sieve with a molecular molar ratio of 65, first impregnated with 100 ml of phosphoric acid solution with a concentration of 6.32 mg / ml for 8 hours, dried at 110°C for 4 hours, and roasted at 550°C for 4 hours, then used 100 ml of LaCl with a concentration of 3.04 mg / ml 3 .6H 2 O solution was impregnated for 8h, dried at 110°C for 4h, and calcined at 550°C for 4h to obtain P-La-ZSM-5.

[0027] (2) Modification of MCM-22 molecular sieve

[0028] Take 100 grams of SiO 2 / Al 2 o 3 Molecular molar ratio is the HMCM-22 molecular sieve of 30, is the Zn(NO of 11 mg / ml with 100 milliliter concentration 3 ).6H 2O solution was impregnated for 8h, dried at 110°C for 4h, and calcined at 550°C for 4h to obtain Zn-MCM-22.

[0029] (3) Catalyst preparation

[0030] 58.5 grams of P-La-ZSM-5...

Embodiment 2

[0032] Catalyst C of the present invention 2 The preparation method is as follows:

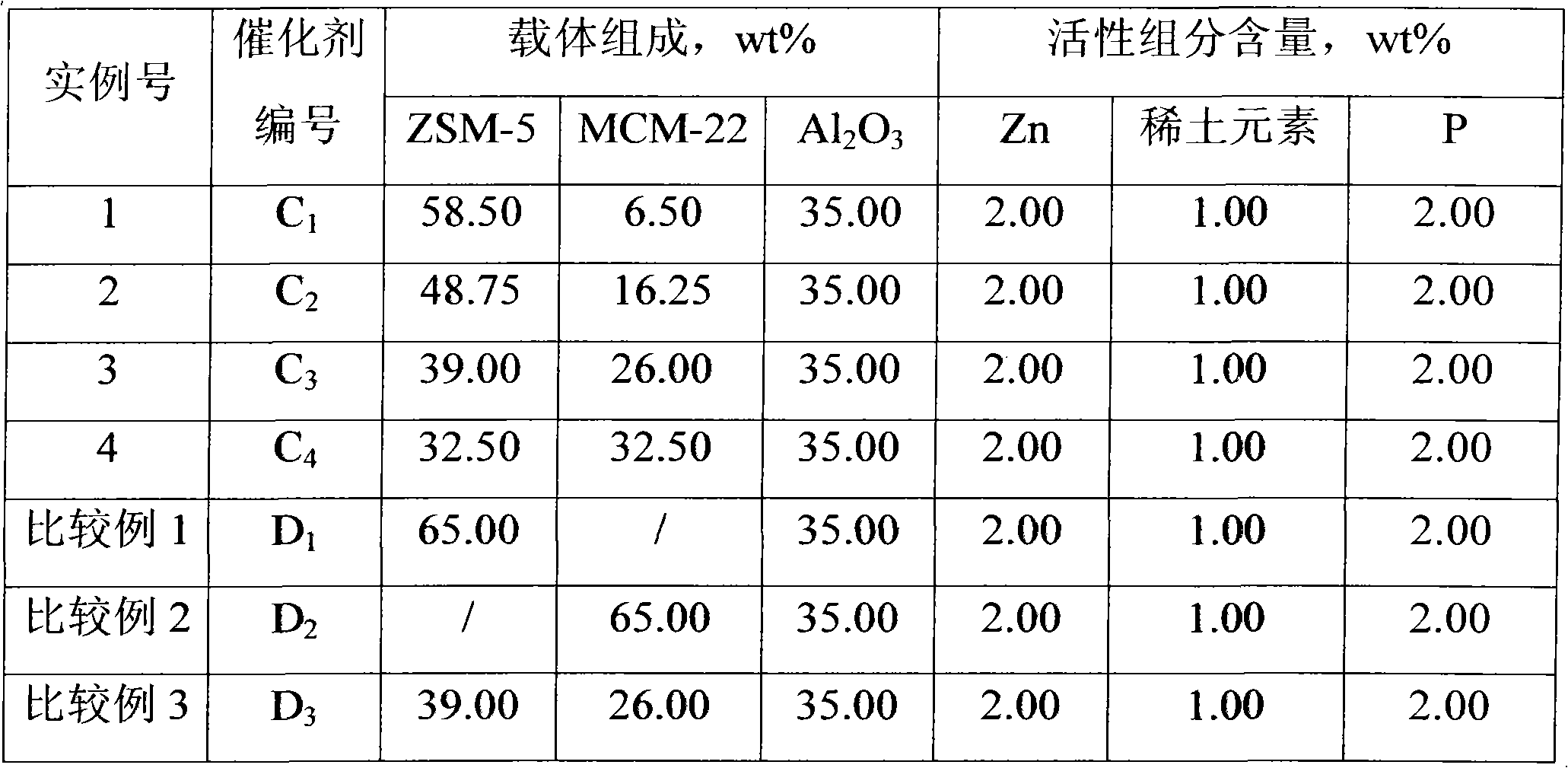

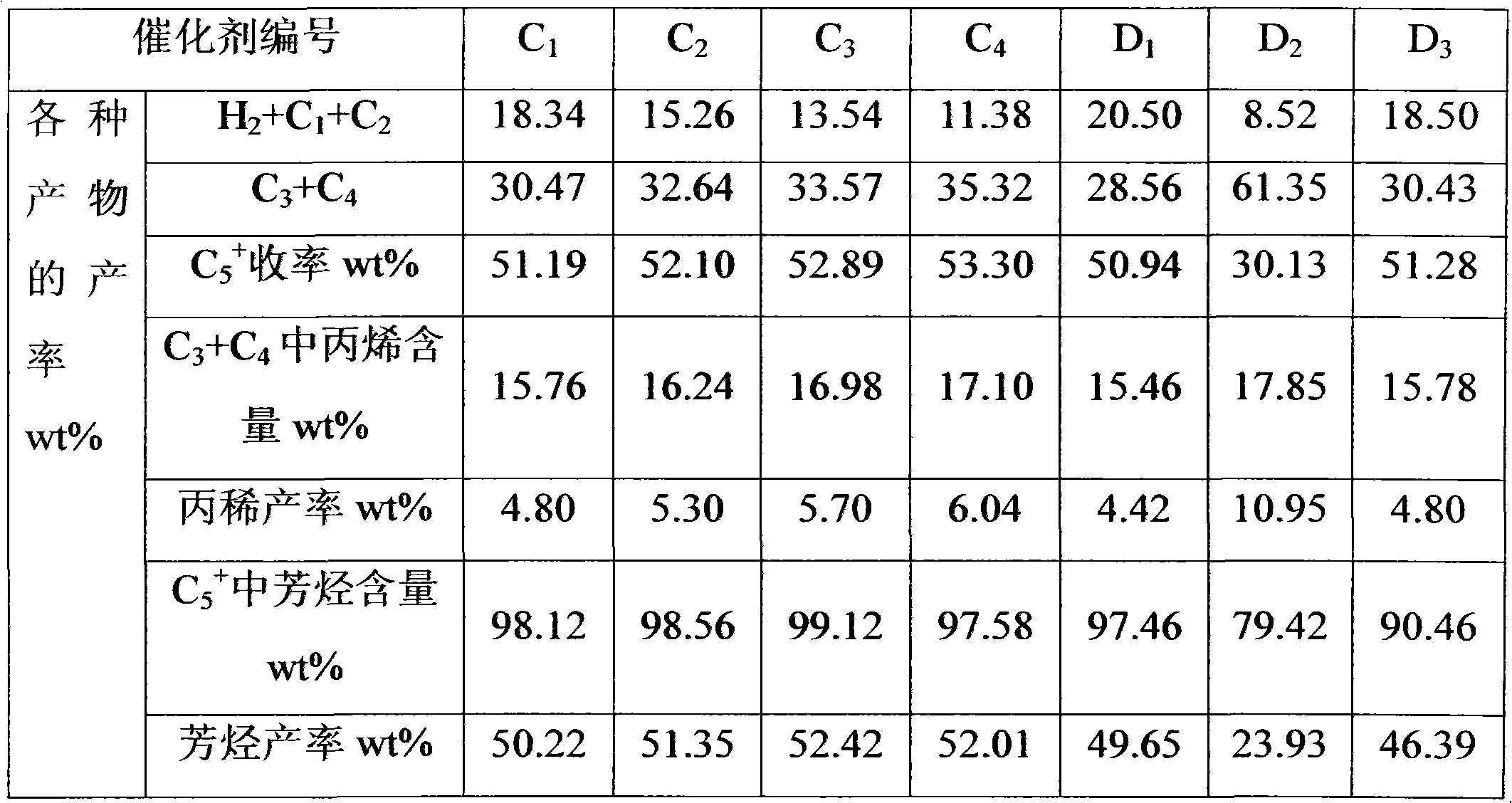

[0033] The preparation method of the catalyst is the same as in Example 1, except that the ratio of P-La-ZSM-5:Zn-MCM-22 in the catalyst carrier is 75:25. The composition is shown in Table 2, and the evaluation results are shown in Table 3.

Embodiment 3

[0035] Catalyst C of the present invention 3 The preparation method is as follows:

[0036] The preparation method of the catalyst is the same as in Example 1, except that the ratio of P-La-ZSM-5:Zn-MCM-22 in the catalyst carrier is 60:40. The composition is shown in Table 2, and the evaluation results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com