Hydrocarbon reforming catalyst containing mesoporous molecular sieve and preparation method thereof

A mesoporous molecular sieve and reforming catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of excessive cracking activity, harsh reaction environment requirements, and affecting aromatics yield and liquid yield and other problems, to achieve high yield of aromatics and increase the yield of isoparaffins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

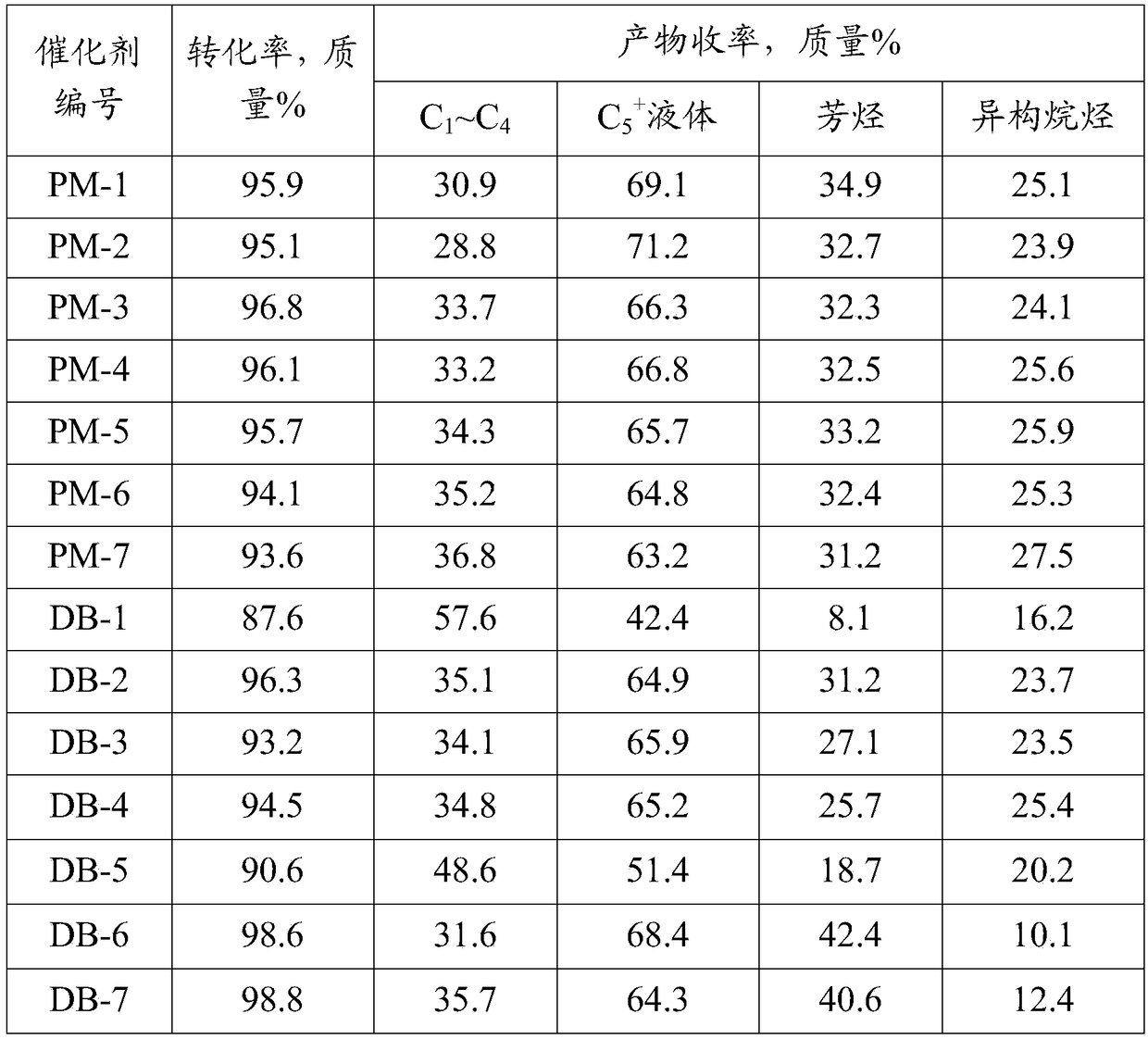

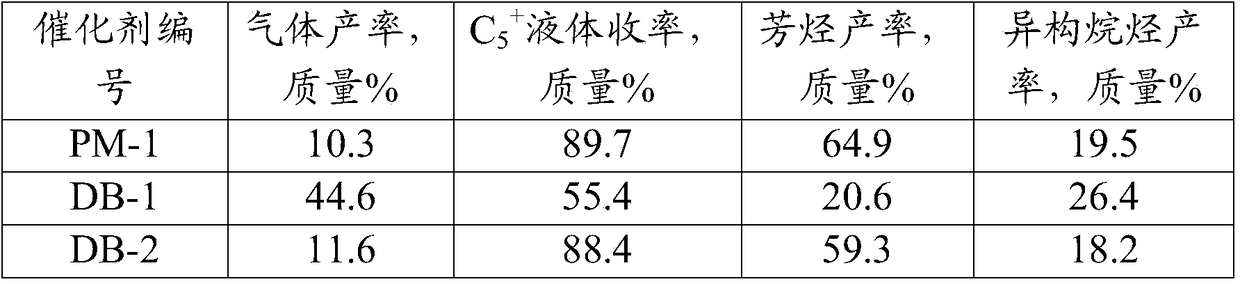

Examples

preparation example Construction

[0033] The preparation method of catalyst of the present invention comprises:

[0034] (1) Make an impregnating solution with a compound containing Group IIIA metals, impregnate a mesoporous molecular sieve, dry and roast the solid, then use a cationic compound containing a platinum group metal to make an impregnating solution, dry and roast the solid to obtain a molecular sieve catalyst,

[0035] (2) impregnating the alumina carrier with an impregnating solution containing an anion containing a platinum group metal compound, a VIIB group metal compound and a halogen, drying the impregnated solid, calcining, reducing, and presulfiding to obtain an alumina catalyst,

[0036] (3) Mix the molecular sieve catalyst prepared in step (1) with the alumina catalyst prepared in step (2) according to the mass ratio of 1-5:1-30.

[0037] In the above method, step (1) is to prepare a molecular sieve catalyst, and the compound containing Group IIIA metal is preferably gallium nitrate hydra...

example 1

[0052] (1) Preparation of SBA-15 molecular sieve

[0053] Dissolve 100g of polyethylene oxide-polypropylene oxide-polyethylene oxide (template agent, referred to as P123, molecular weight 5800, produced by Aldrich, USA) in 2250mL of deionized water, add 1500g of hydrochloric acid with a concentration of 4mol / L Stir evenly, slowly add 212.5 g of ethyl orthosilicate at 40° C., and stir for 4 hours. Then the obtained mixture was transferred into an autoclave, aged at 140°C for 24 hours, filtered, washed, dried at 120°C for 8 hours, and calcined at 550°C for 4 hours to obtain a white powder, which was SBA-15 molecular sieve.

[0054] (2) Preparation of Ga / SBA-15 molecular sieve

[0055] Ga (NO 3 ) 3 The solution was prepared with an appropriate amount of deionized water to make an impregnation solution, so that the Ga content in it was 1.0% by mass (relative to the mass of the molecular sieve on a dry basis), the liquid / solid volume ratio was 5: 1, and the SBA-15 molecular siev...

example 2

[0063] (1) Preparation of MCM-41 molecular sieve

[0064] Take 9.9g of cetyltrimethylammonium bromide, add 205.1mL of deionized water, and stir at 60°C for 0.5 hours. 140.7 mL of ammonia water with a concentration of 25% by mass was added dropwise, stirring was continued for 0.5 hours, 50.4 mL of ethyl orthosilicate and 205.1 mL of deionized water were added, and stirring was continued for 6 hours. The obtained mixture was transferred into an autoclave, aged at 110°C for 4 days, filtered and washed, dried at 120°C for 8 hours, and calcined at 550°C for 4 hours to obtain a white powder, which was MCM-41 molecular sieve.

[0065] (2) get MCM-41 molecular sieve, use Ga(NO by the method of example 1 (2) step 3 ) 3 The supported gallium is impregnated with the solution, dried and calcined to prepare the MCM-41 molecular sieve containing 1.0 mass% Ga (relative to the mass of the molecular sieve on a dry basis).

[0066] (3) get the MCM-41 molecular sieve that contains 1.0 mass % ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com