Laser preparation method of iron-based amorphous nanometer crystalline coat

An iron-based amorphous and nanocrystalline technology, which can be used in coatings, metal material coating processes, etc., can solve problems such as preparation and processing difficulties, and achieve the effects of reducing raw material costs, high interface bonding strength, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The composition of the cladding powder material is calculated by weight percentage: 29.5% Ni, 18% Si, 18% B, 2% Nb, 3% Cr, the rest is Fe, and the particle size range of the powder is 75-150 microns. First, the iron-based alloy coating was prepared on the low-carbon low-alloy steel CCS-B substrate by laser cladding, and then the coating surface was subjected to laser rapid remelting treatment. Laser cladding parameters are: laser power 5.5KW, spot diameter 5mm, cladding speed 500mm / min, powder feeding volume 20g / min, side blowing argon gas flow rate 20L / min. The laser remelting parameters are: laser power 14KW, spot diameter 4mm, scanning speed 8m / min, argon gas flow 30L / min.

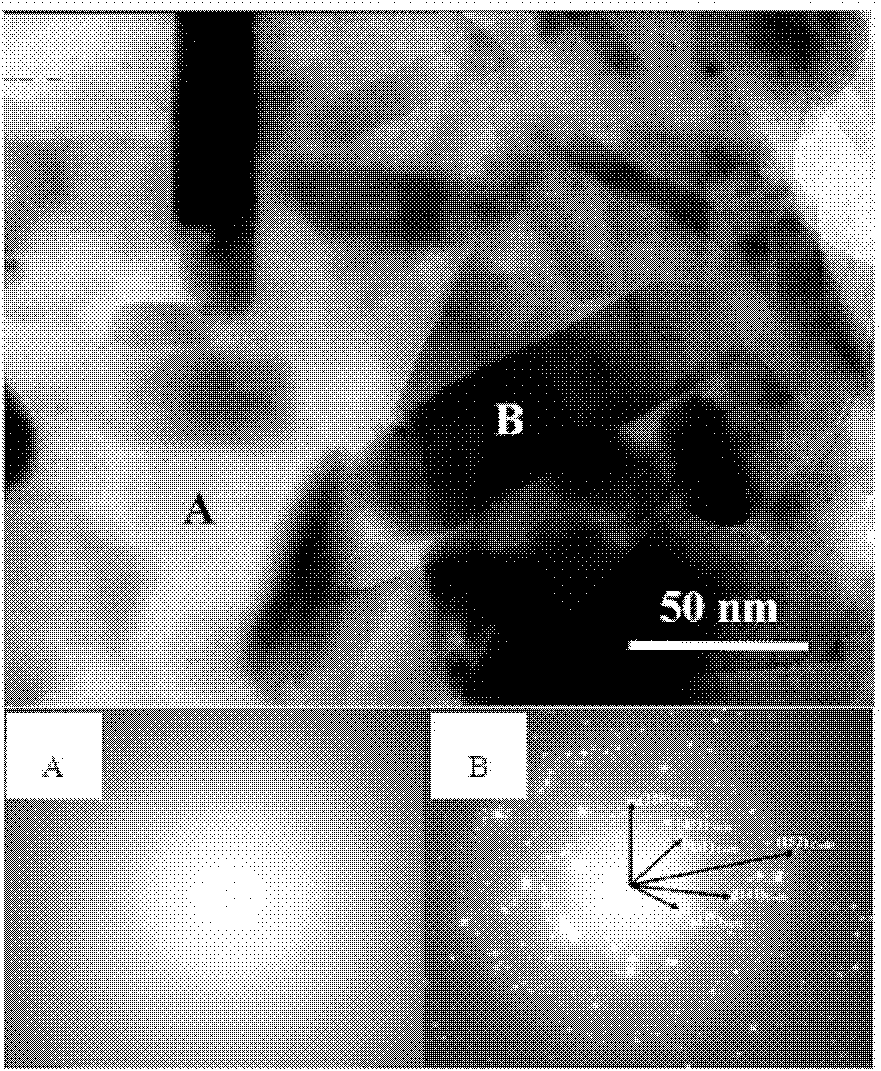

[0017] Such as figure 1 As shown, the coating structure is a black nano-scale particle phase distributed on a white substrate. The amorphous halo of the white matrix indicates that the matrix is an amorphous phase, and the diffraction spots of the black rod-shaped particle phase indicate that...

Embodiment 2

[0019] The composition of the cladding powder material is calculated by weight percentage: 30.25% Ni, 18% Si, 18% B, 2% Nb, 1.5% Y, the rest is Fe, and the particle size range of the powder is 75-150 microns. First, the iron-based alloy coating was prepared on the low-carbon low-alloy steel CCS-B substrate by laser cladding, and then the coating surface was subjected to laser rapid remelting treatment. Laser cladding parameters are: laser power 5.5KW, spot diameter 5mm, cladding speed 500mm / min, powder feeding volume 20g / min, side blowing argon gas flow rate 20L / min. The laser remelting parameters are: laser power 14KW, spot diameter 4mm, scanning speed 8m / min, argon gas flow 30L / min.

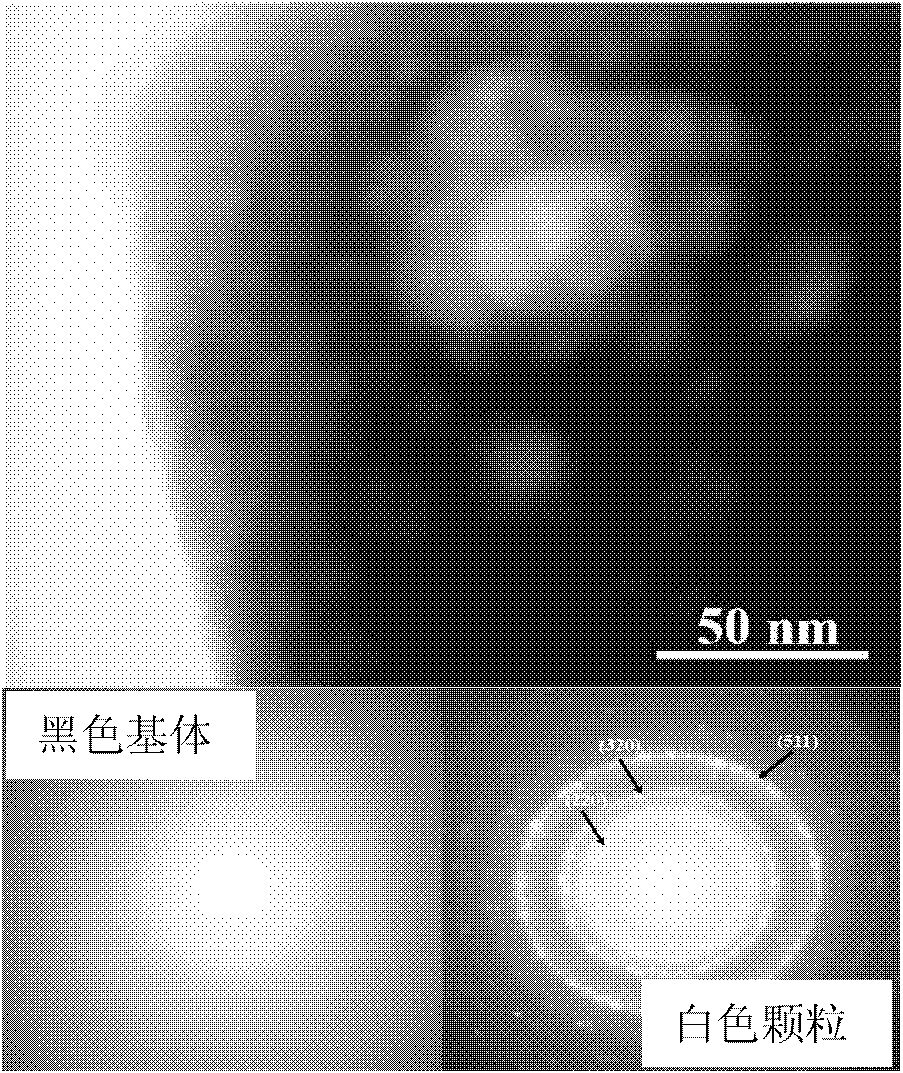

[0020] Such as figure 2 As shown, the coating structure is nano-sized black particles dispersed on the white substrate. The amorphous halo of the white matrix indicates that the matrix is an amorphous phase, and the diffraction spots of black particles indicate that the organization is γ-(...

Embodiment 3

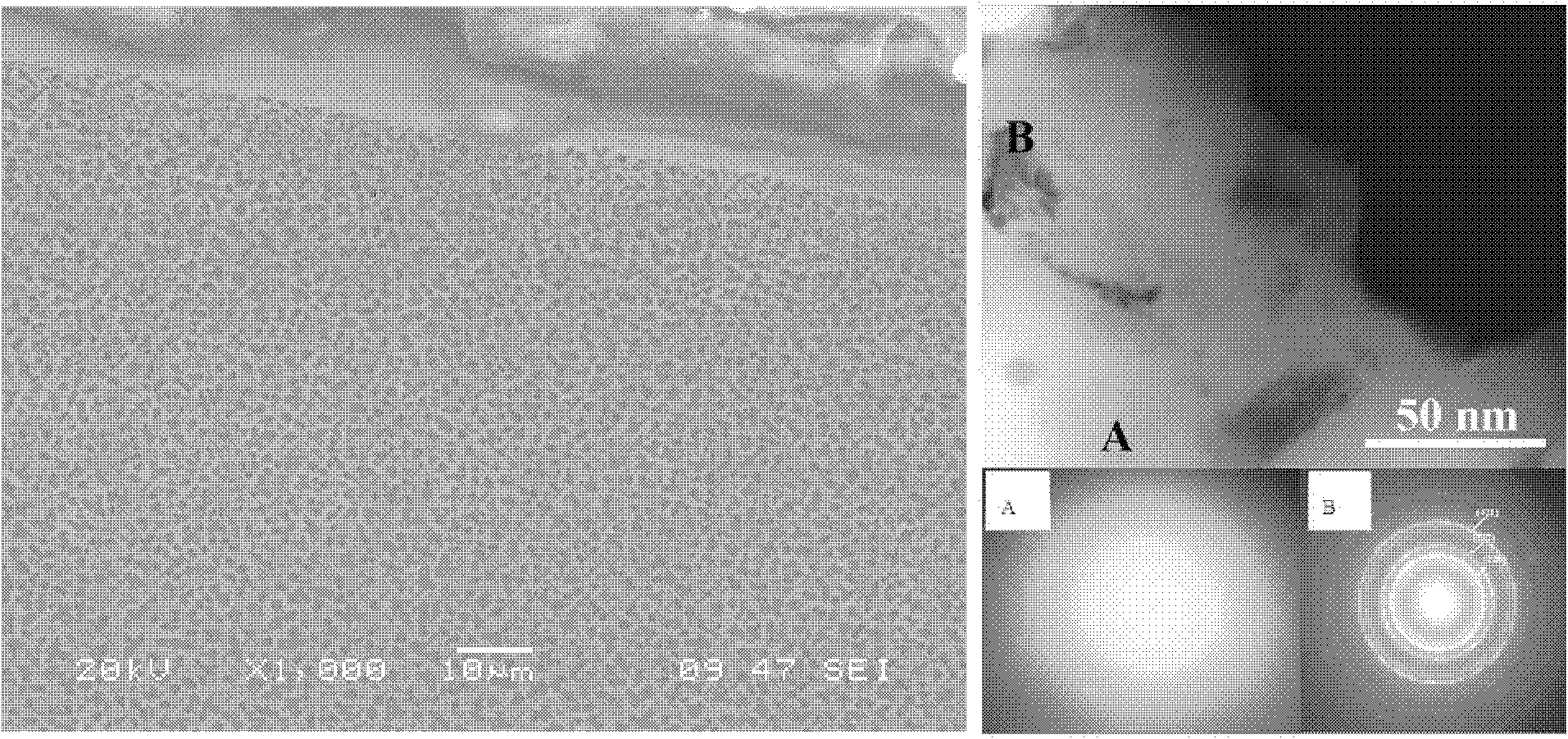

[0022] The composition of the cladding powder material is the same as in Example 2, calculated by weight percentage: 30.25% Ni, 18% Si, 18% B, 2% Nb, 1.5% Y, and the rest is Fe; but the pure element is added in Example 2 The powders are different. The cladding powder in this embodiment is added in the form of pure iron powder, pure nickel powder, ferrosilicon powder, ferroboron powder, niobium ferrosilicon powder and rare earth yttrium-based ferrosilicon powder, and the cost of raw materials is greatly reduced; after mixing, ball milling After 1 hour, the particle size of the powder ranged from 75-150 microns. First, the iron-based alloy coating was prepared on the low-carbon low-alloy steel CCS-B substrate by laser cladding, and then the coating surface was subjected to laser rapid remelting treatment. Laser cladding parameters are: laser power 5.5KW, spot diameter 5mm, cladding speed 500mm / min, powder feeding volume 20g / min, side blowing argon gas flow rate 20L / min. The las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com