Method for stopping leakage of gas pipeline without gas stopping and welding

A technology for gas pipelines and plugging methods, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the risk of explosion that cannot be solved in a fundamental sense, the life of the mixture is difficult to meet the requirements, and the plugging operation It can achieve obvious economic and social benefits, major economic and social benefits, and easy plugging and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

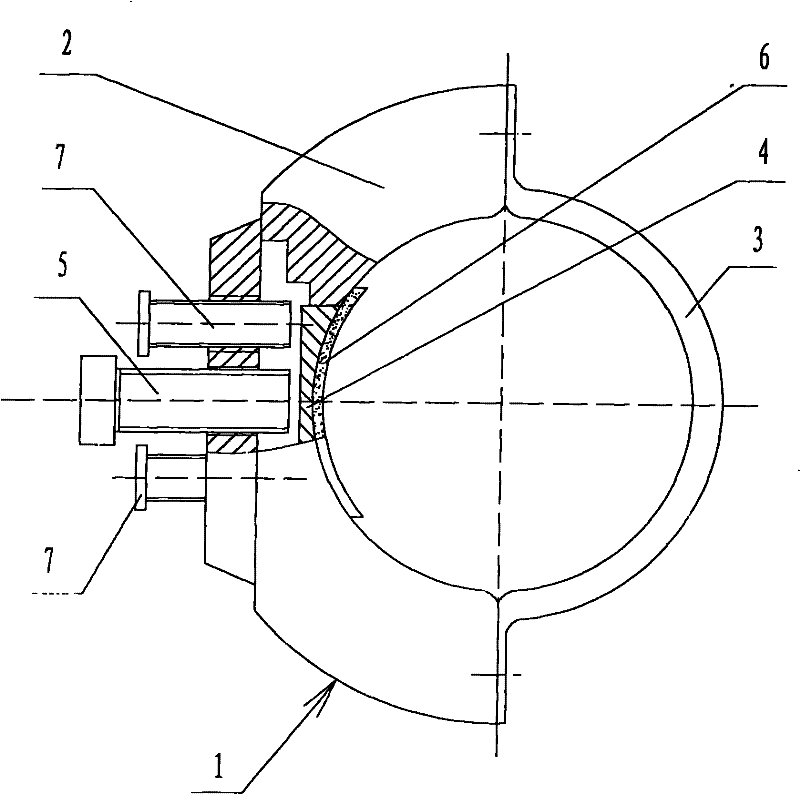

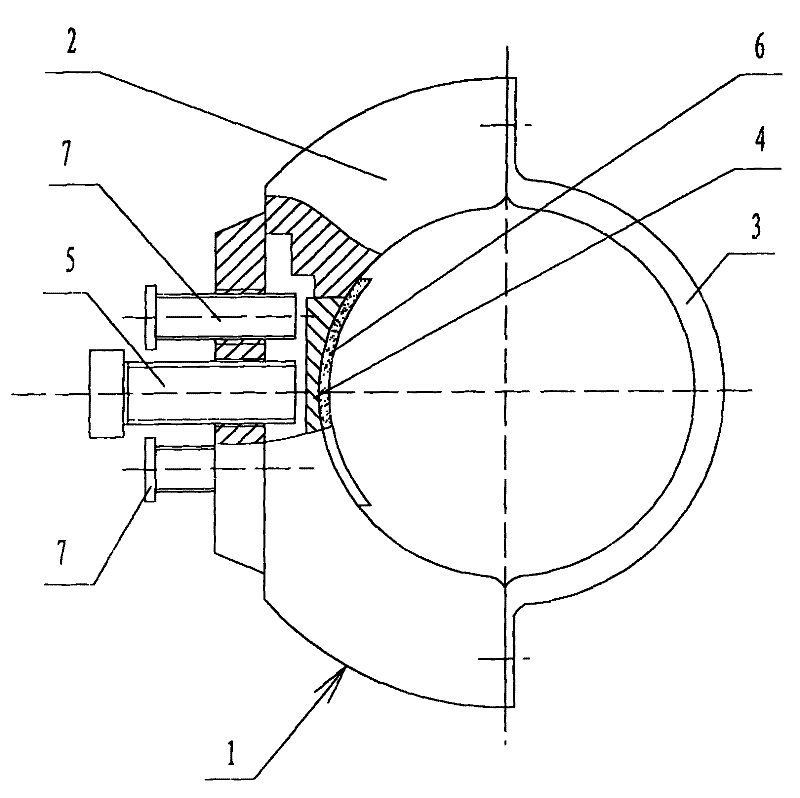

[0020] The leak-stopping method of the gas pipeline of the present invention without stopping gas and welding, comprises the following steps:

[0021] 1. Find the leakage point of the gas pipeline, and clean up the anti-corrosion substances, rust and impurities on the surface of the pipeline around the leakage point;

[0022] 2. Choose a plugging device that matches the diameter of the gas pipeline and install it around the leak point of the gas pipeline; choose a soft sealing briquette that matches the size of the leak point and place it between the plugging device and the leak point of the gas pipeline between;

[0023] 3. By rotating the compression screw of the leakage plugging device, the compression screw drives the arc-shaped compression block to push the soft sealing compact to press against the leakage point until the soft sealing compact completely blocks the leakage point, and the leakage point no longer until it leaks out;

[0024] 4. Tighten the fine-tuning anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com