Speckle making method for deformation measurement in high temperature environment

A technology of high temperature environment and production method, applied in the field of experimental mechanics, can solve the problems of affecting accuracy and complicated production method, and achieve the effects of low production cost, simple operation and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

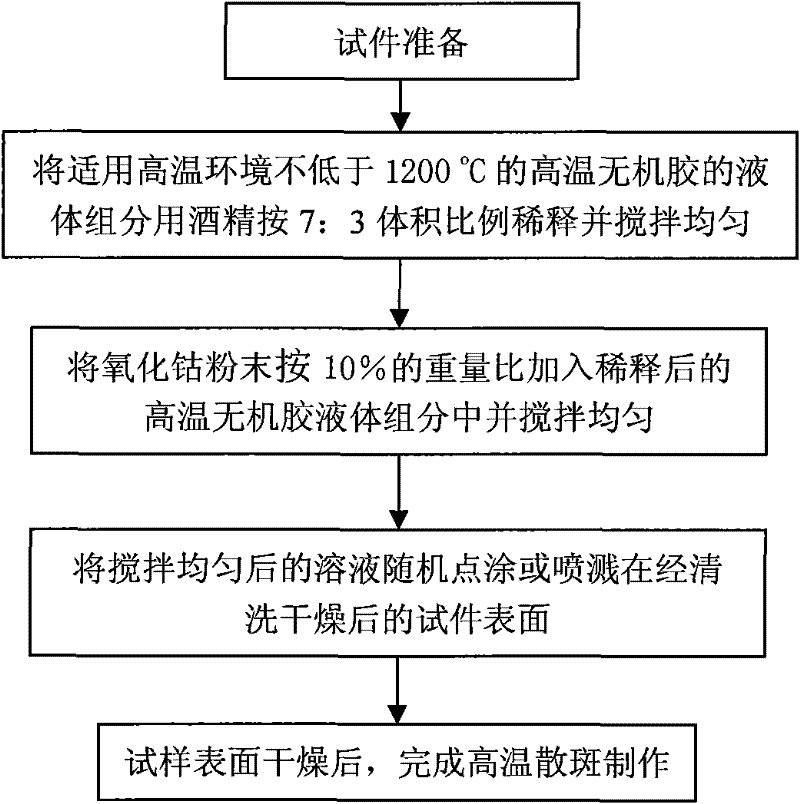

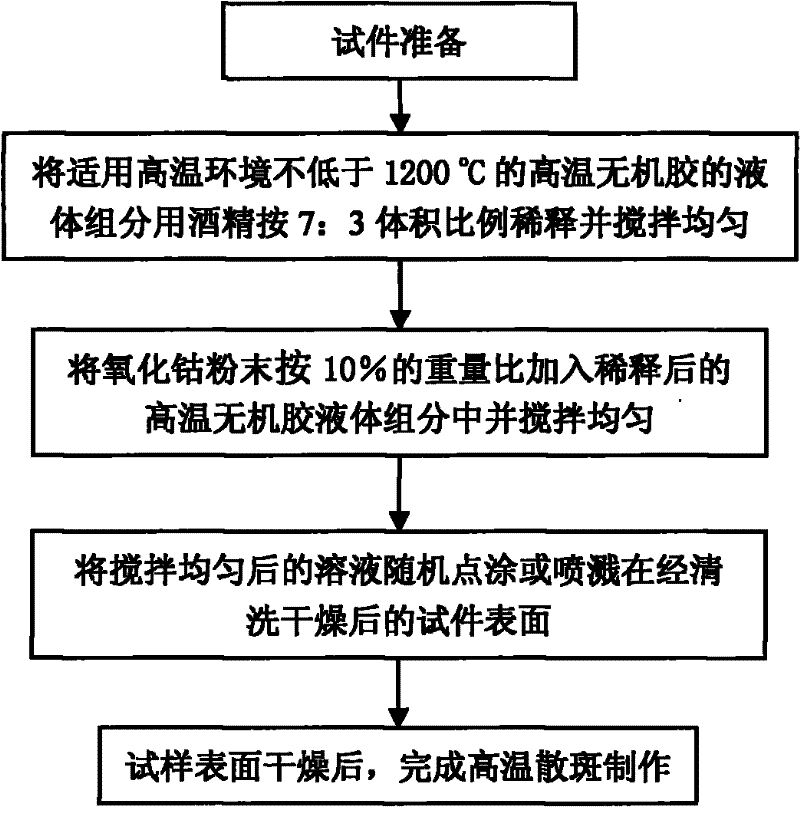

[0024] figure 1 It is an operation flowchart of a speckle production method for high-temperature environment deformation measurement according to the present invention, and its specific operation steps are as follows:

[0025] a. Select the material of the test piece to be chromium-nickel austenitic stainless steel (material grade 1Cr19Ni9Ti), cut the test piece into a shape of 100mm×100mm×2mm (length×width×thickness), and then use acetone on its surface Wipe dry with cotton balls and dry after cleaning;

[0026] b. Dilute the liquid component of the high-temperature inorganic glue of model Ak04-4 produced by Beijing Aoyukexin Surface Engineering Technology Co., Ltd. with alcohol in a volume ratio of 7:3 and stir evenly;

[0027] c. adding the cobalt oxide powder to the liquid component of the diluted high-temperature inorganic glue in a weight ratio of 10%;

[0028] d. Randomly apply the solution with cobalt oxide powder on the surface of the cleaned and dried test piece wi...

Embodiment 2

[0031] a. Select the material of the test piece to be 310S stainless steel, cut the test piece into a shape of 100mm×100mm×2mm (length×width×thickness), then clean the surface with acetone and dry it with a cotton ball ;

[0032] b. Dilute the liquid component of the high-temperature inorganic glue of model Ak04-4 produced by Beijing Aoyukexin Surface Engineering Technology Co., Ltd. with alcohol in a volume ratio of 7:3 and stir evenly;

[0033] c. adding the cobalt oxide powder to the liquid component of the diluted high-temperature inorganic glue in a weight ratio of 10%;

[0034] d. Randomly spray the solution added with cobalt oxide powder on the surface of the cleaned and dried test piece with a brush;

[0035] e. Place it at room temperature for 24 hours. After the surface of the sample is dried and solidified, the high-temperature artificial speckle is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com