Method for producing mandrel by utilizing 28NiCrMoV steel as raw material

A technology of raw materials and mandrels, applied in the direction of metal rolling, manufacturing tools, mandrels, etc., can solve the problems of difficult guarantee of transverse impact toughness and high production cost, and achieve the elimination of flaky pearlite, uniform structure and composition, and cooling speed Fast, grain-refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

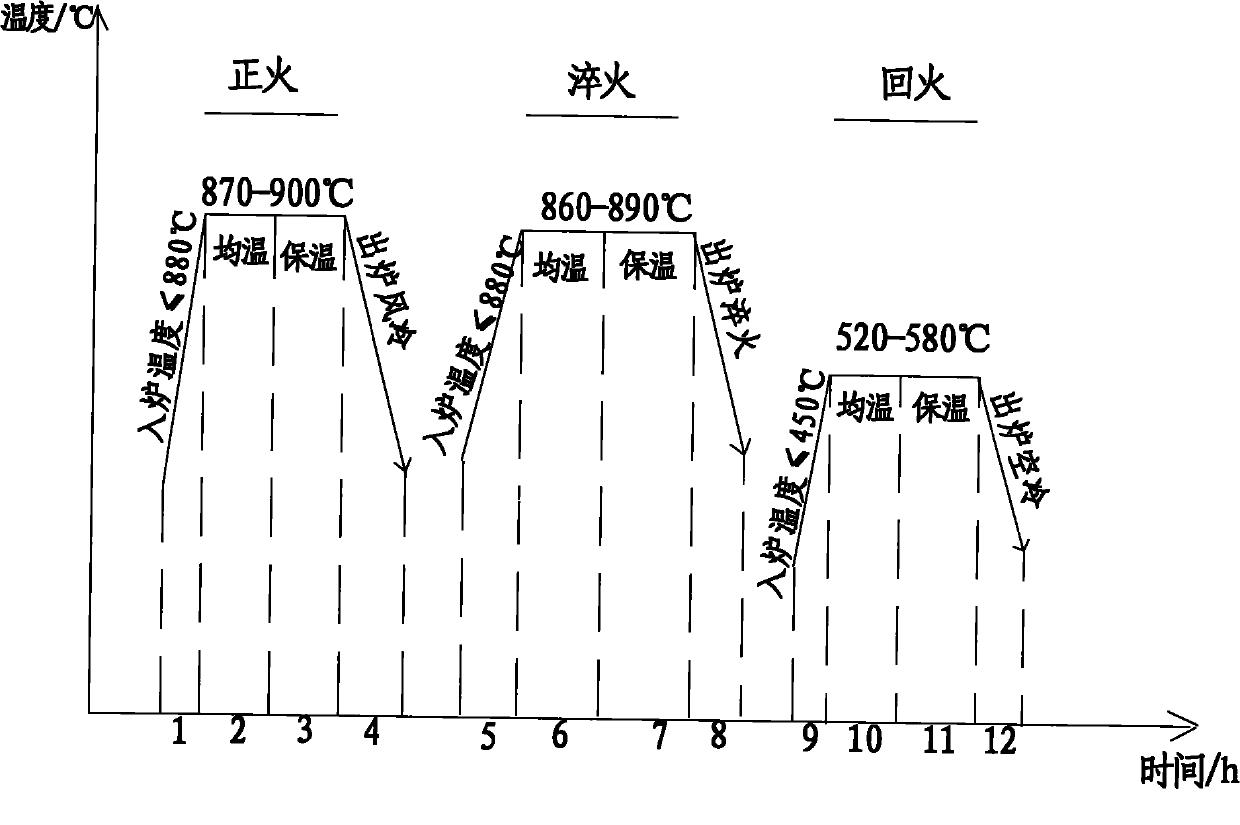

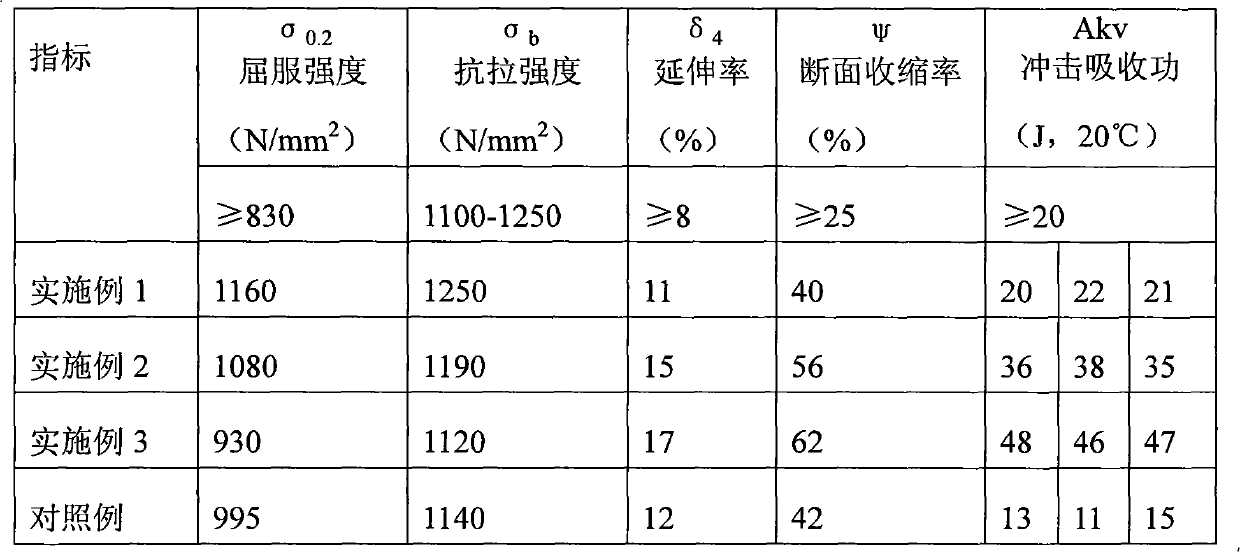

[0013] Example 1: The mandrel steel type is 28NiCrMoV10, which is formed by material selection-refining-forging-rough machining-heat treatment-finishing. After material selection, the EAF+LF / VD refining method is adopted, and the furnace charge is made of secondary or above Composed of steel scrap, return material head, high-quality steelmaking pig iron, sponge iron, etc., tap after EAF oxidation, pre-deoxidize and partially alloy in the ladle, carry out LF / VD argon blowing refining, weakly stir before tapping, and use after tapping and calming Argon protection pouring, hot forging after stripping the steel ingot, controlled chemical composition during the refining process: C = 0.26-0.32%, Si = 0.30-0.50%, Mn = 0.20-0.40%, Ni = 2.30-2.60%, Cr =0.70~0.90%, Mo=0.55~0.70%, V=0.25~0.32%, S≤0.005%, P≤0.013%; then heated in the bottom gas furnace, the temperature of the heating furnace is 1150℃, the temperature of the billet is allowed 20°C lower than the furnace temperature to ensu...

Embodiment 2

[0014] Example 2: The mandrel steel type is 28NiCrMoV10, which is formed by material selection-refining-forging-rough machining-heat treatment-finishing. After material selection, the EAF+LF / VD refining method is adopted, and the furnace charge is made of secondary or above Composed of steel scrap, return material head, high-quality steelmaking pig iron, sponge iron, etc., tap after EAF oxidation, pre-deoxidize and partially alloy in the ladle, carry out LF / VD argon blowing refining, weakly stir before tapping, and use after tapping and calming Argon protection pouring, hot forging after stripping the steel ingot, controlled chemical composition during the refining process: C = 0.26-0.32%, Si = 0.30-0.50%, Mn = 0.20-0.40%, Ni = 2.30-2.60%, Cr =0.70~0.90%, Mo=0.55~0.70%, V=0.25~0.32%, S≤0.005%, P≤0.013%; then heated in the bottom type gas furnace, the temperature of the heating furnace is 1180℃, and the temperature of the billet is allowed 40°C lower than the furnace temperatur...

Embodiment 3

[0015] Example 3: The mandrel steel type is 28NiCrMoV10, which is formed by material selection-refining-forging-rough machining-heat treatment-finishing. After material selection, the EAF+LF / VD refining method is adopted, and the charge is made of secondary or above Composed of steel scrap, return material head, high-quality steelmaking pig iron, sponge iron, etc., tap after EAF oxidation, pre-deoxidize and partially alloy in the ladle, carry out LF / VD argon blowing refining, weakly stir before tapping, and use after tapping and calming Argon protection pouring, hot forging after stripping the steel ingot, controlled chemical composition during the refining process: C = 0.26-0.32%, Si = 0.30-0.50%, Mn = 0.20-0.40%, Ni = 2.30-2.60%, Cr =0.70~0.90%, Mo=0.55~0.70%, V=0.25~0.32%, S≤0.005%, P≤0.013%; and then heated in a car-bottom gas furnace, the temperature of the heating furnace is 1200°C, and the temperature of the billet is allowed 50°C lower than the furnace temperature to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com