Method for preparing environment-friendly aromatic oil from catalytic cracking slurry oil

A technology for catalytic cracking of oil and aromatic oil, applied in the field of chemical industry and materials, can solve the problem of low content of toxic polycyclic aromatic hydrocarbons, achieve low raw material and operating costs, and be easy to put into industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

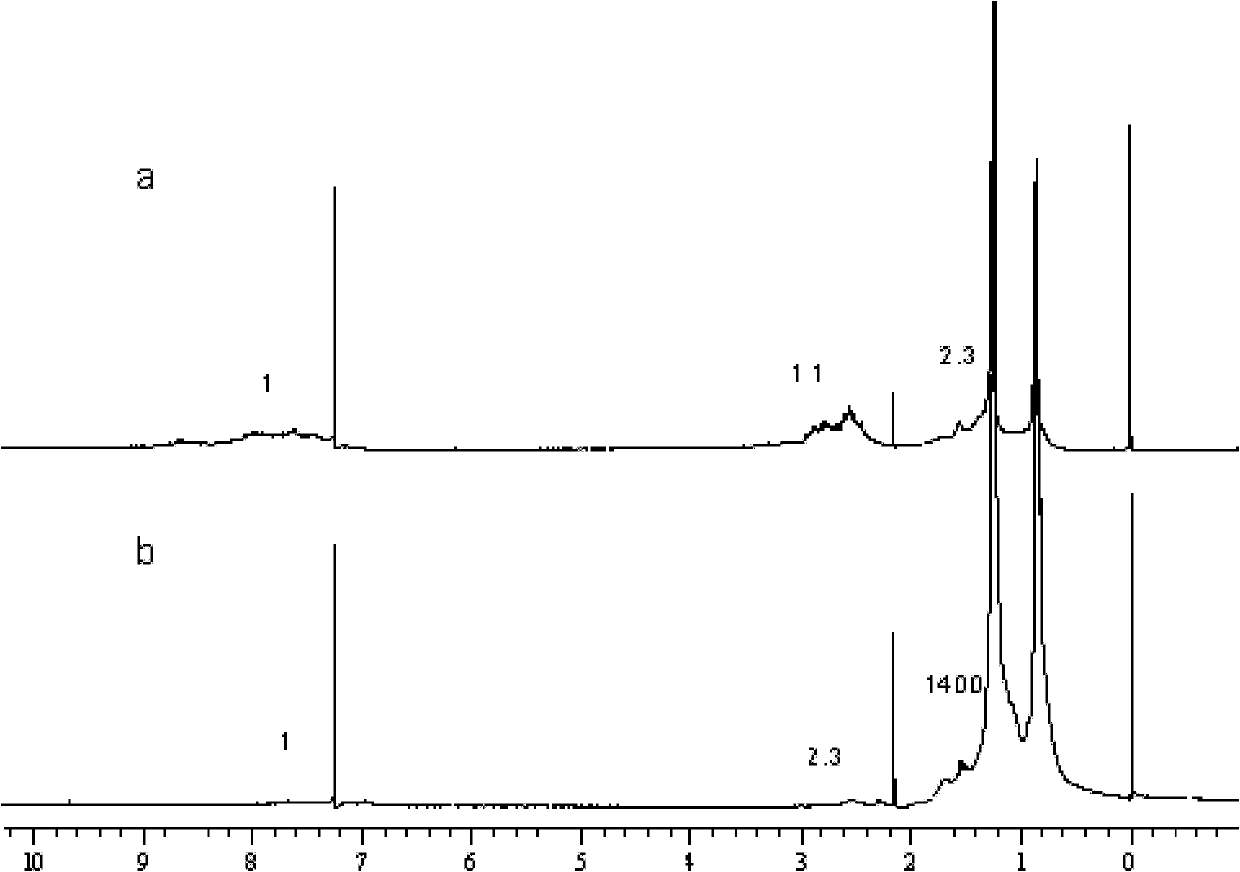

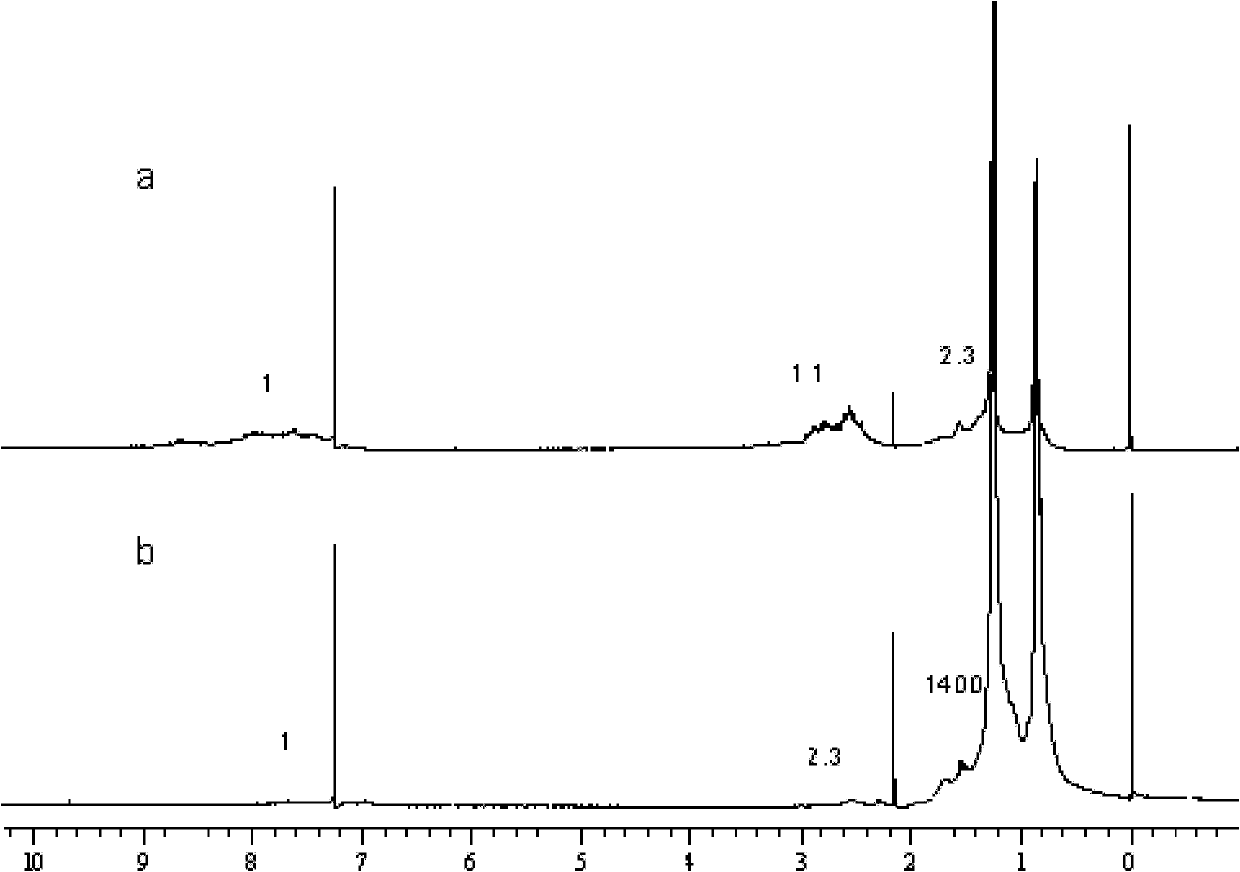

[0024] Add 40g of catalytic cracking oil slurry produced in the Yangtze River Basin after removal of catalyst particles and dewaxing, 30mL of petroleum ether with a boiling point of 60-90°C, and 15mL of furfural into the extraction tank. For the extraction tank, see figure 1 , heated to 45°C, stirred for 20 minutes, then allowed to stand for stratification, separated the lower layer solution, then added 10mL furfural, stirred at 45°C for 20 minutes, stood for stratification, separated the lower layer solution, and then re- Use 5mL furfural to extract 10 times according to the above-mentioned operation successively; After the sherwood oil is evaporated off at last remaining supernatant solution, obtain environmental protection aromatic oil 4.18g, productive rate 10.2%, the recovery rate based on the content of useful aromatic oil in the catalytic oil slurry is 52%. Through IP346 method analysis, the polycyclic aromatic hydrocarbon content in the gained environment-friendly arom...

Embodiment 2

[0026] Add 40g of catalytic cracking oil slurry (produced in the Yangtze River Basin) after removal of catalyst particles and dewaxing, 30mL of 90-120°C petroleum ether, and 15mL of furfural into the extraction tank, heat to 30°C, stir for 30Min, and then stand to separate layer, after separating the lower layer solution, add 10mL furfural, stir at 30°C for 30Min, then stand to separate layers. The lower layer solution was separated, and the remaining upper layer solution was extracted 10 times with 5 mL furfural according to the above operation. After the petroleum ether was evaporated from the upper layer solution, 4.62 g of environmentally friendly aromatic oil was obtained, with a yield of 11.8% and a recovery of 58% (based on the content of useful aromatic oil in the catalytic oil slurry). According to IP346 method analysis, the content of polycyclic aromatic hydrocarbons in the obtained environmentally friendly aromatic oil is less than 2.93%; through high-pressure liqui...

Embodiment 3

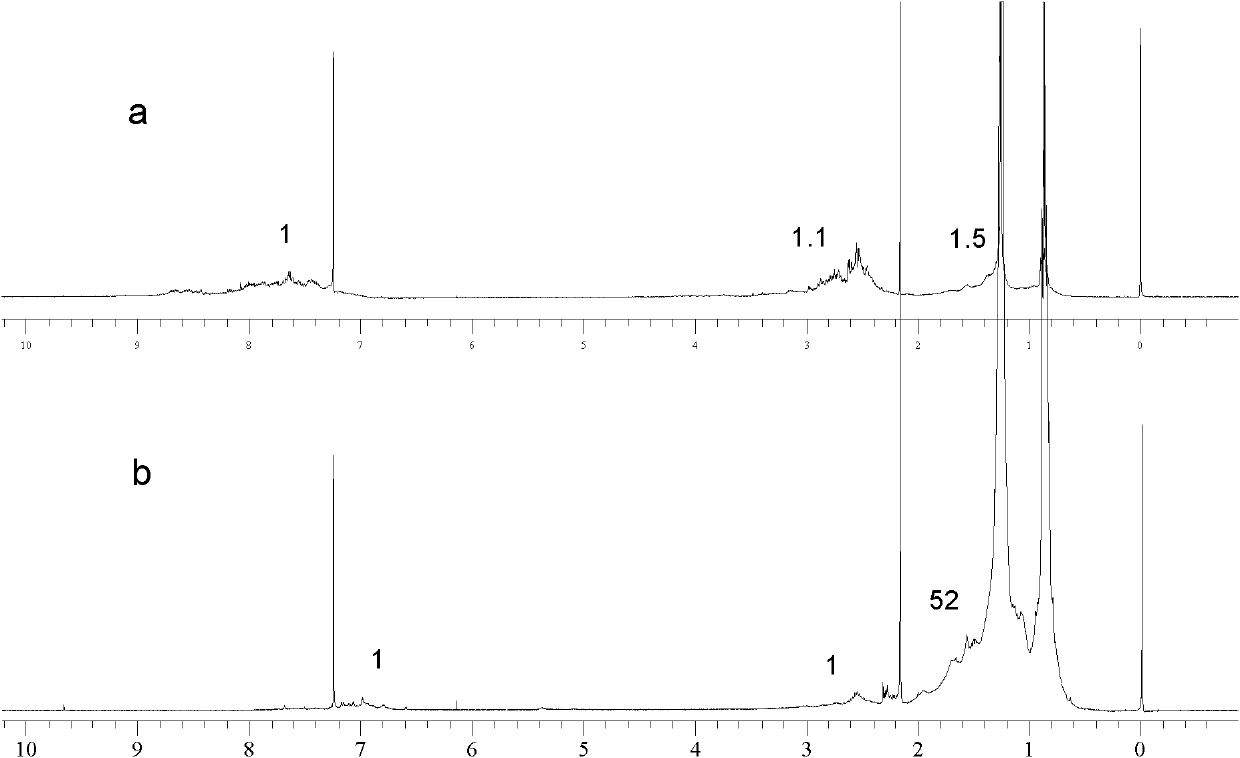

[0028] Add 80g of catalytic cracking oil slurry (produced in Karamay) after removal of catalyst particles and dewaxing, 60mL of petroleum ether at 60-90°C, and 20mL of furfural into the extraction tank, heat to 50°C, stir for 10Min, and then stand to separate layers . After the lower layer solution was separated, 20 mL of furfural was added, stirred at 50°C for 10 min, and allowed to stand to separate layers. The lower layer solution was separated, and the remaining upper layer solution was sequentially extracted 10 times with 10 mL furfural according to the above operation. After the petroleum ether was evaporated from the upper layer solution, 18.4 g of environmentally friendly aromatic oil was obtained, with a yield of 22.9% and a recovery of 76.3% (based on the content of useful aromatic oil in the catalytic oil slurry). Analyzed by IP346 method, the content of polycyclic aromatic hydrocarbons in the obtained environment-friendly aromatic oil is less than 2.66%; analyzed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com