Patents

Literature

229 results about "N-methylpyrrole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Methylpyrrole 99% CAS Number 96-54-8. Empirical Formula (Hill Notation) C 5 H 7 N . Molecular Weight 81.12 . Beilstein Registry Number 104181 . EC Number 202-513-7. MDL number MFCD00005345. PubChem Substance ID 24897193. SDS Specification Sheet (PDF) FTNMR (PDF) Similar Products.

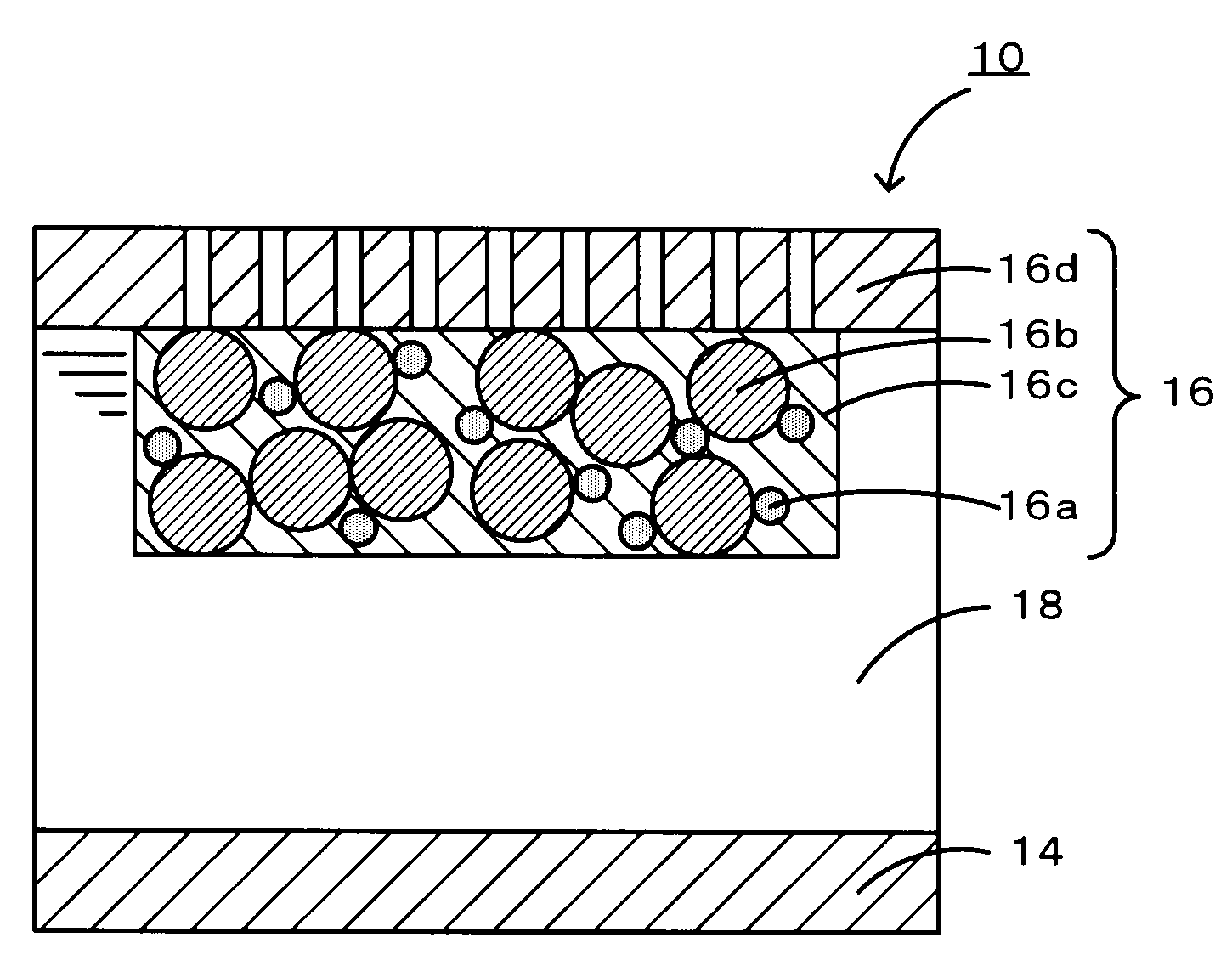

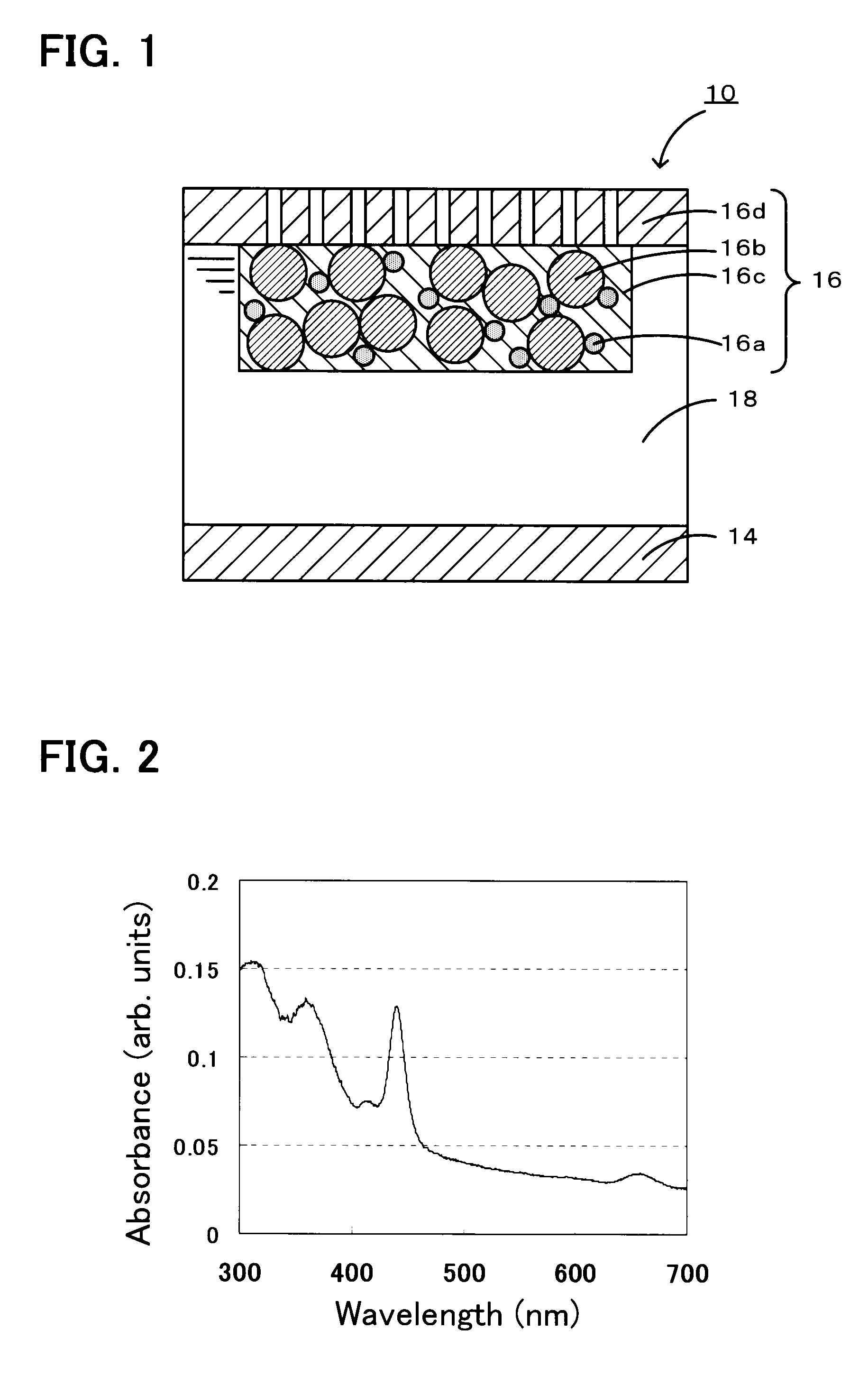

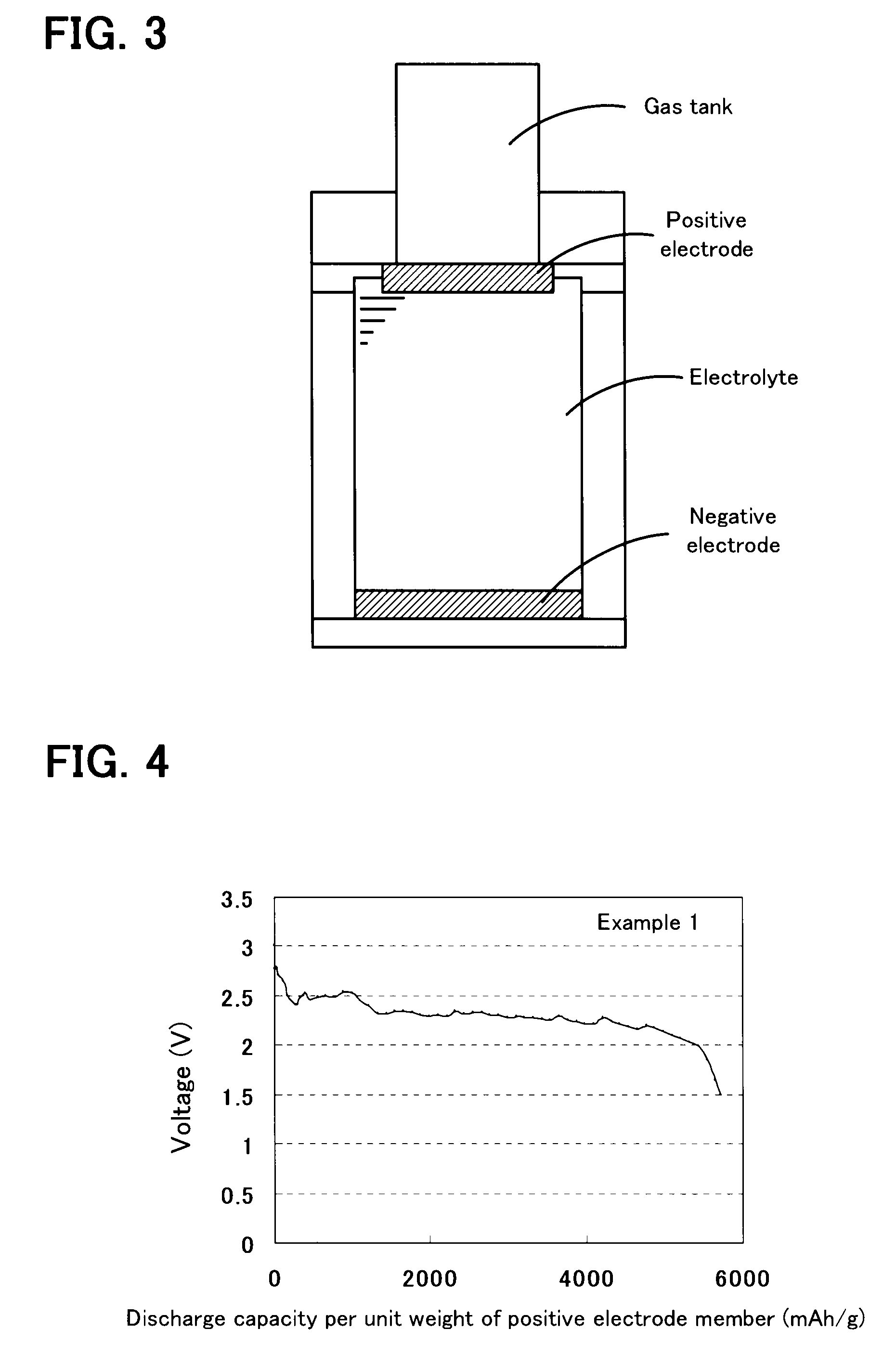

Non-aqueous air battery and catalyst therefor

InactiveUS20080299456A1Improve discharge capacityIncrease energy densityFuel and secondary cellsNon-aqueous electrolyte accumulator electrodesPorphyrinOxygen

A non-aqueous air battery of the present invention includes a negative electrode for which a material which absorbs and releases lithium ions is used as a negative electrode active material, a positive electrode for which oxygen is used as a positive electrode active material, and a non-aqueous electrolyte disposed between the negative electrode and the positive electrode. The positive electrode contains a donor-acceptor molecule in which an electron-donating donor (D) having a porphyrin ring is connected to an electron-accepting acceptor (A) composed of a fullerene derivative, with a conductive spacer therebetween. An example of the donor-acceptor molecule is triphenylporphyrinyl bithienyl N-methylpyrrolidino[60]fullerene.

Owner:TOYOTA CENT RES & DEV LAB INC

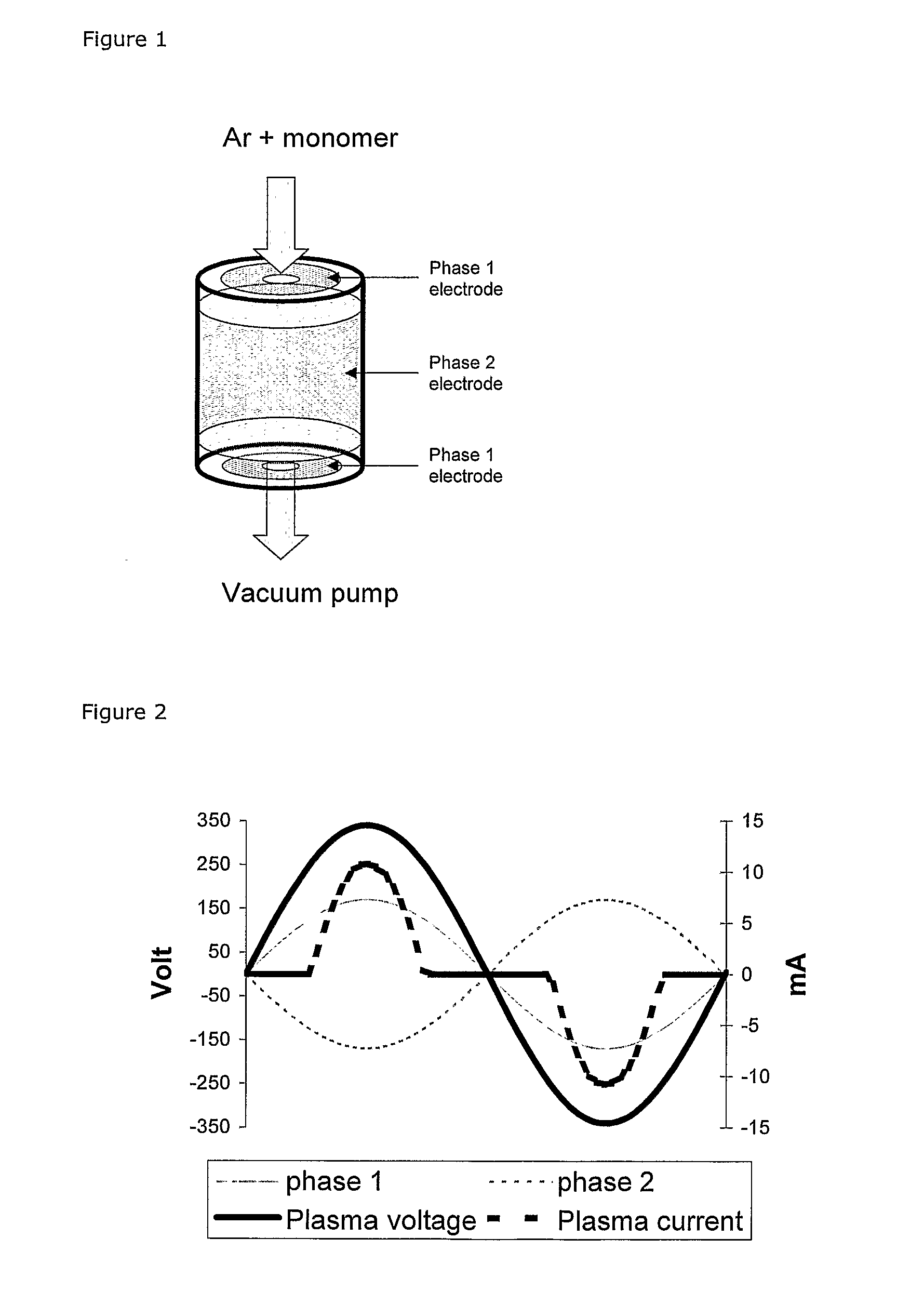

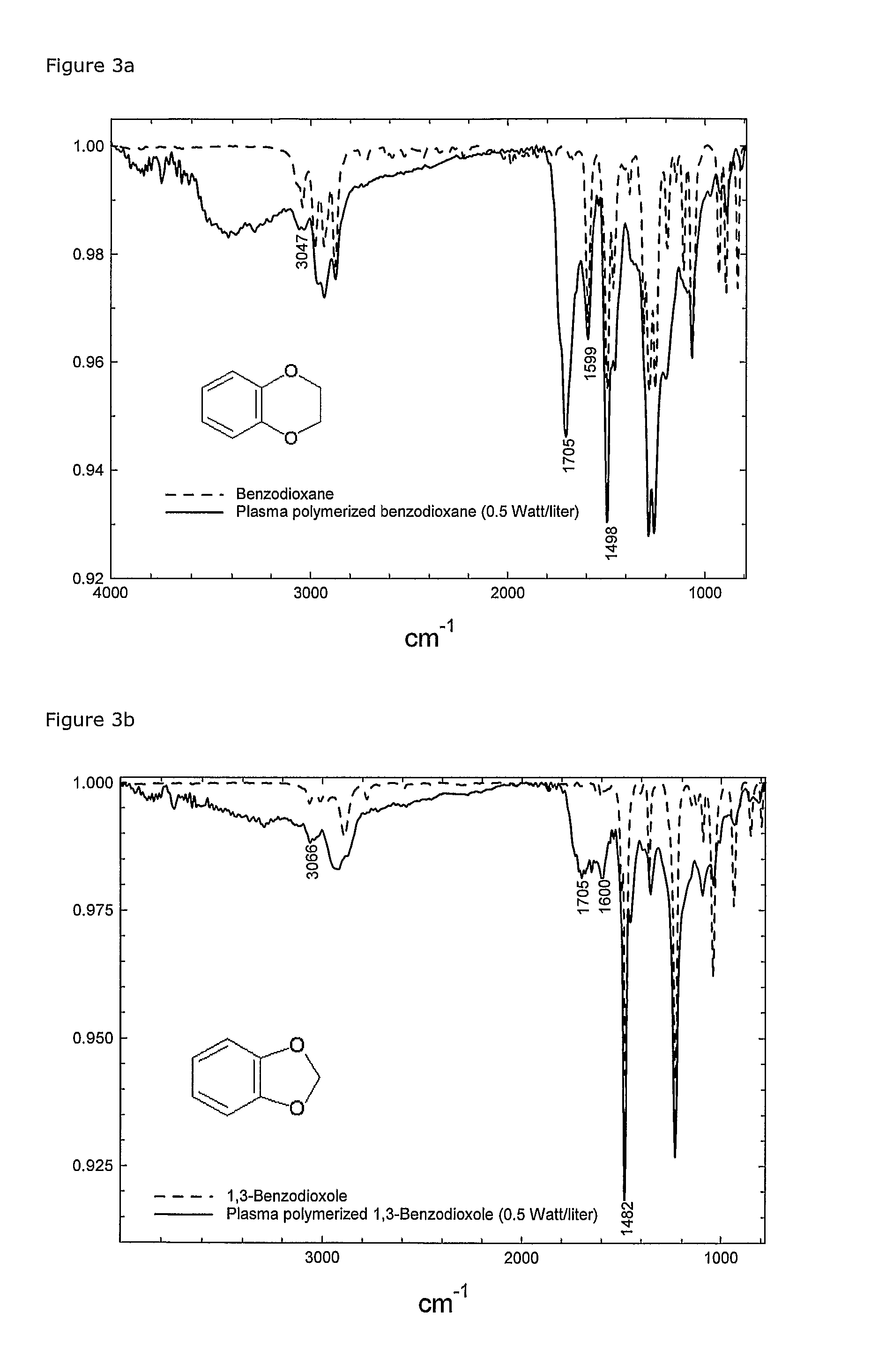

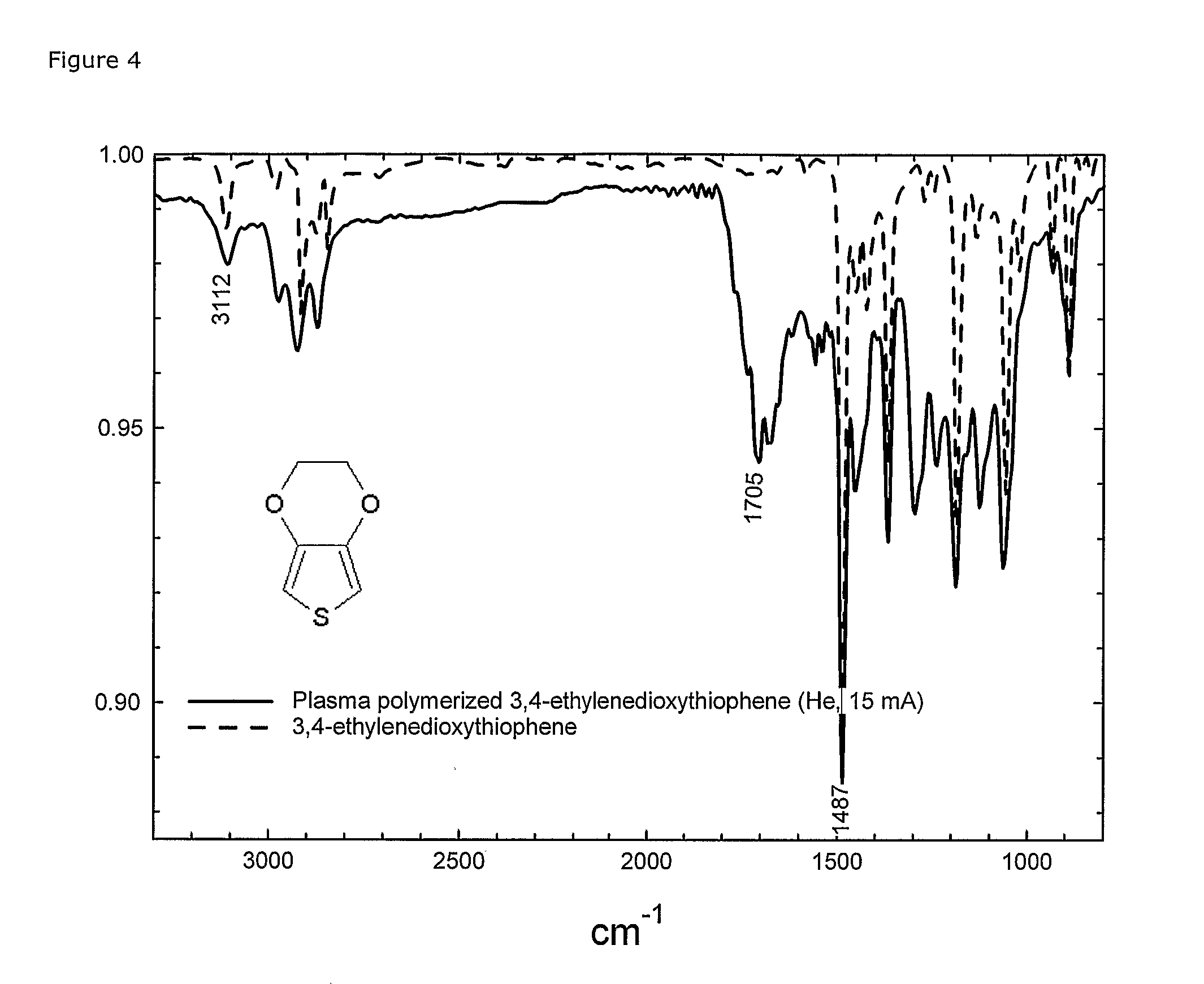

Plasma-Polymerisation Of Polycylic Compounds

InactiveUS20070202612A1Liquid surface applicatorsSynthetic resin layered productsPolycyclic compoundEthylenedioxy

The present invention relates to a method for the preparation of a layer of a plasma-polymerised material on the surface of a substrate, e.g. a substrate of a glass, an organosiloxane-based or polysiloxane-based material, silicon, fluoro-polymer (e.g. Teflon®), etc. The present invention also relates to novel objects and microstructured or micro-patterned devices, e.g. by lift-off techniques, in particular such objects and devices that have layers of electrically conducting materials providing a conductivity of at least 0.01 S / cm. A feature of the invention is the plasma-polymerization of a compound including at least one polycyclic compound, said polycyclic compound(s) comprising a non-aromatic heterocyclic ring fused to an aromatic or heteroaromatic ring or ring system. Examples of such compounds are 3,4-ethylenedioxythiophene (EDT) forming layers of poly(ethylenedioxythiophene) (PEDT), and piperonylamine, piperonyloyl chloride, safrole, 3,4-ethylenedioxypyrrole, 3,4-ethylenedioxy-N-methylpyrrole, and 3,4-methylenedioxythiophene.

Owner:DANMARKS TEKNISKE UNIV

Diamond nonstick coating composition and preparation method thereof

The invention discloses a diamond nonstick coating composition and a preparation method thereof. The coating composition comprises a primer and a finishing coat, wherein the primer comprises the following components in percentage by weight: 1-5% of carbon black, 5-10% of a surfactant, 10-32% of polytetrafluoroethylene, 10-20% of N-methylpyrrolidone, 30-50% of water, 0-5% of diamond powder and 5-15% of bonding resin, totally 100%; the finishing coat comprises the following components in percentage by weight: 5-20% of a surfactant, 35-50% of polytetrafluoroethylene, 20-40% of water, 0-5% of diamond powder and 15-19% of an organic solvent, totally 100%; the percentages by weight of the diamond powder in the primer and finishing coat are not zero at the same time. The diamond nonstick coating composition disclosed by the invention has excellent coating pencil hardness, heat conductivity and wear resistance.

Owner:SHANGHAI MINGFU NEW MATERIAL TECH CO LTD

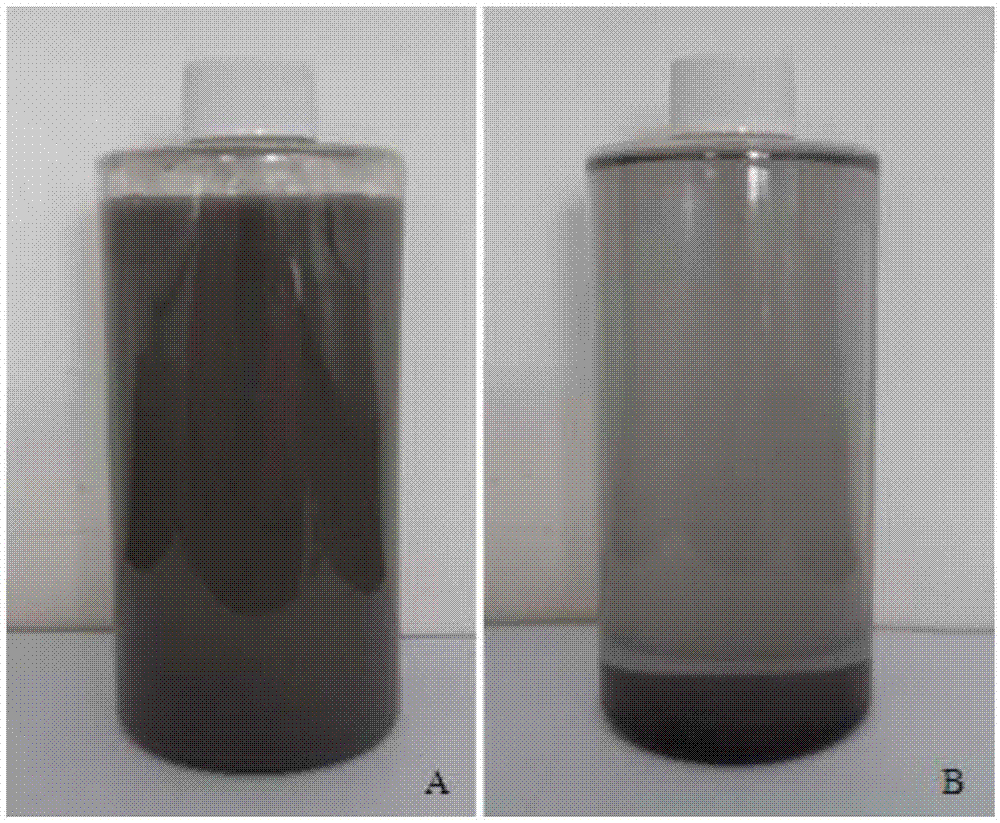

Method for preparing environment-friendly aromatic oil from catalytic cracking slurry oil

InactiveCN101906317AEasy to put inLow raw material costTreatment with plural serial refining stagesPolycyclic aromatic hydrocarbonSlurry

The invention provides a method for preparing environment-friendly aromatic oil from catalytic cracking slurry oil. The environment-friendly aromatic oil which meets the European 2005 / 69 / EC directive is prepared by performing repeated extraction with double solvents on the catalytic cracking slurry oil by using an alkyl solvent with small polarity and the solvents such as furfural, N-methylpyrrolidone, dimethyl sulfoxide and the like with large polarity. Toxic polycyclic aromatic hydrocarbon in the obtained environment-friendly aromatic oil is less than 3 percent, and the benzopyrene content is less than 0.1ppm, so the oil can be used as environment-friendly rubber filling oil and environment-friendly aromatic oil for other purposes.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of lithium battery anode slurry

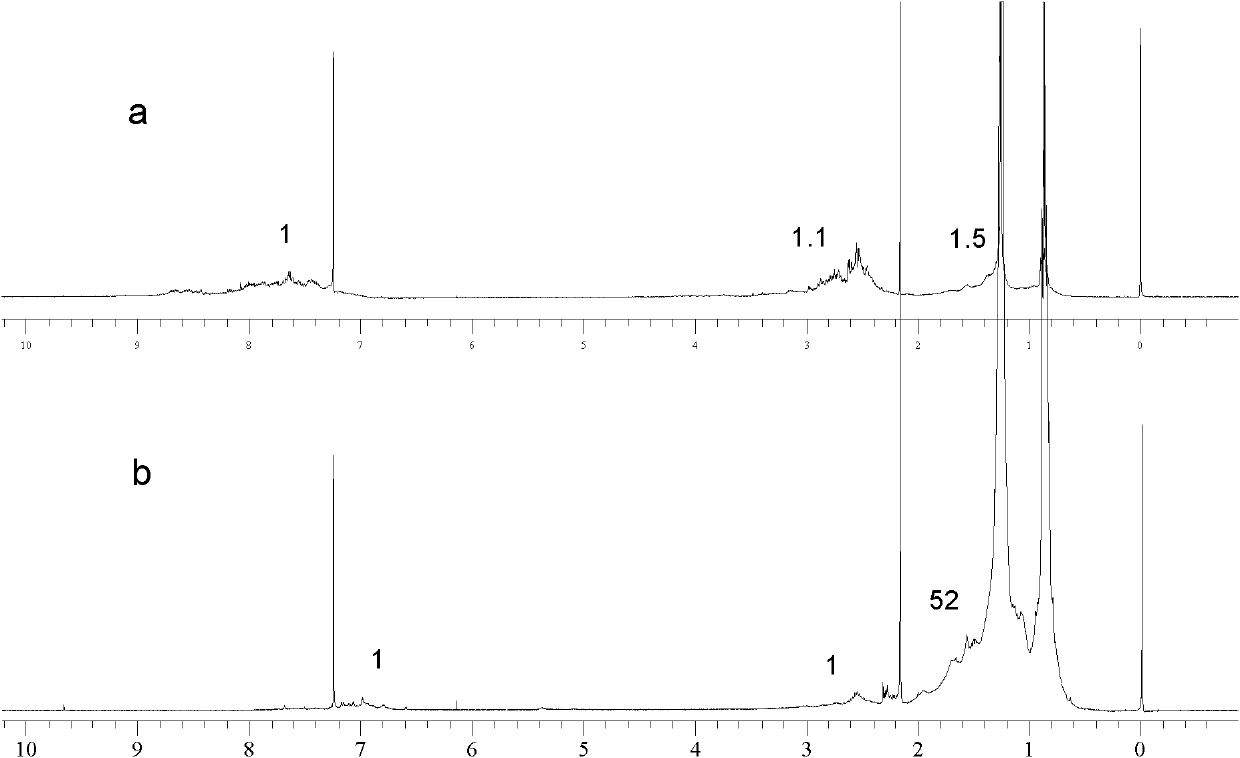

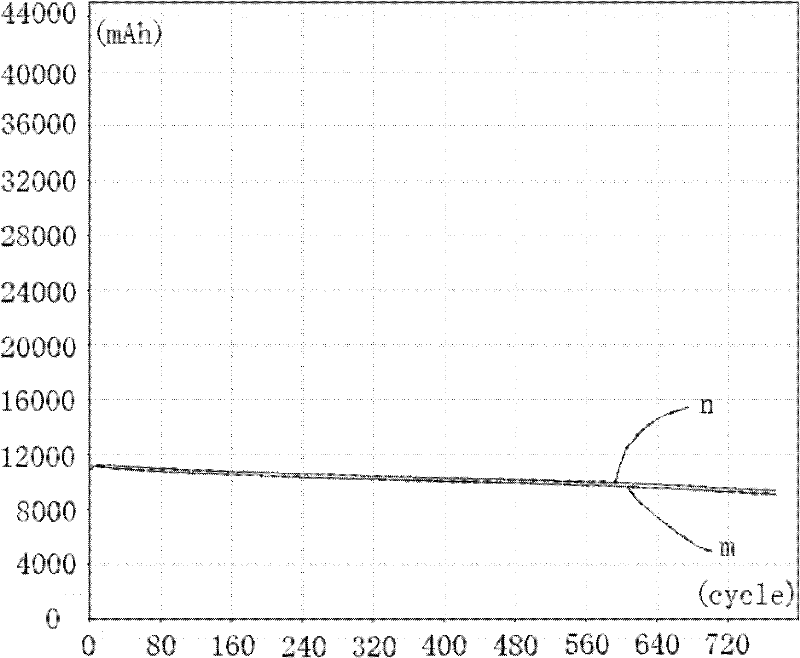

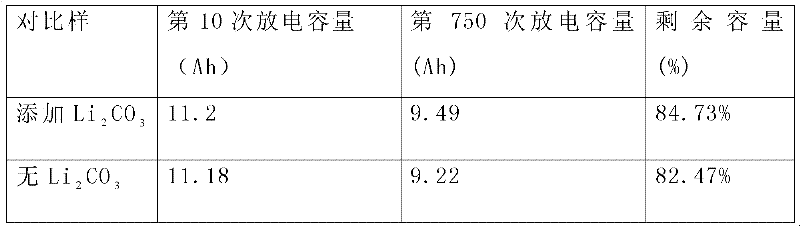

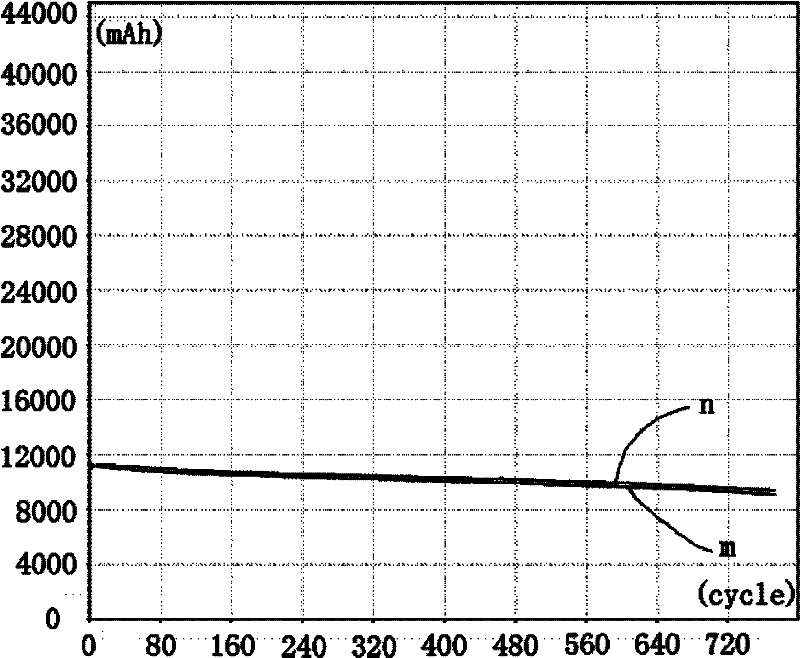

The invention relates to a preparation method of lithium battery anode slurry. The preparation method comprises the following steps of 1, preparing a glue solution through the processes of putting a right amount of N-methylpyrrolidone (NMP) and a right amount of polyvinylidene fluoride (PVDF) into a vacuum dispersator, and carrying out vacuum-pumping and stirring, b, carrying out preblend of a conductive agent, an active material and Li2CO3, adding the mixture of the conductive agent, the active material and Li2CO3 into the glue solution obtained by the step 1, and stirring for 3 to 5 hours, and c, testing viscosity of the solid-liquid mixture obtained by the step b, and adding N-methylpyrrolidone (NMP) into the solid-liquid mixture to adjust the viscosity of the solid-liquid mixture so that the viscosity the solid-liquid mixture satisfies a coating requirement. The preparation method of the lithium battery anode slurry has the advantages of simple operation and preparation processes. The preparation method of the lithium battery anode slurry also has the advantages of improving production efficiency, reducing energy consumption, reducing a total amount of gas produced by subsequent formation of a lithium battery prepared from the lithium battery anode slurry, increasing battery reversible capacity, and realizing the optimal cycle performance.

Owner:陈恒龙

Nonaqueous electrolyte secondary battery separator, nonaqueous electrolyte secondary battery laminated separator, nonaqueous electrolyte secondary battery member, and nonaqueous electrolyte secondary battery

InactiveUS20170155120A1Inhibit deteriorationGood rate characteristicsNon-aqueous electrolyte accumulatorsCell component detailsMicrowavePolyolefin

Provided is a nonaqueous electrolyte secondary battery separator including a porous film containing polyolefin as a main component, the nonaqueous electrolyte secondary battery separator having a time until temperature rise cessation with respect to an amount of resin per unit area of 2.9 sec·m2 / g to 5.7 sec·m2 / g, the time being obtained in a case where the nonaqueous electrolyte secondary battery separator is impregnated with N-methyl pyrrolidine containing 3 wt % water and is subsequently irradiated, at an output of 1,800 W, with a microwave having a frequency of 2,455 MHz, the nonaqueous electrolyte secondary battery separator having an excellent initial rate characteristic and being capable of preventing a deterioration in rate characteristic which deterioration is caused by repeated charge and discharge.

Owner:SUMITOMO CHEM CO LTD

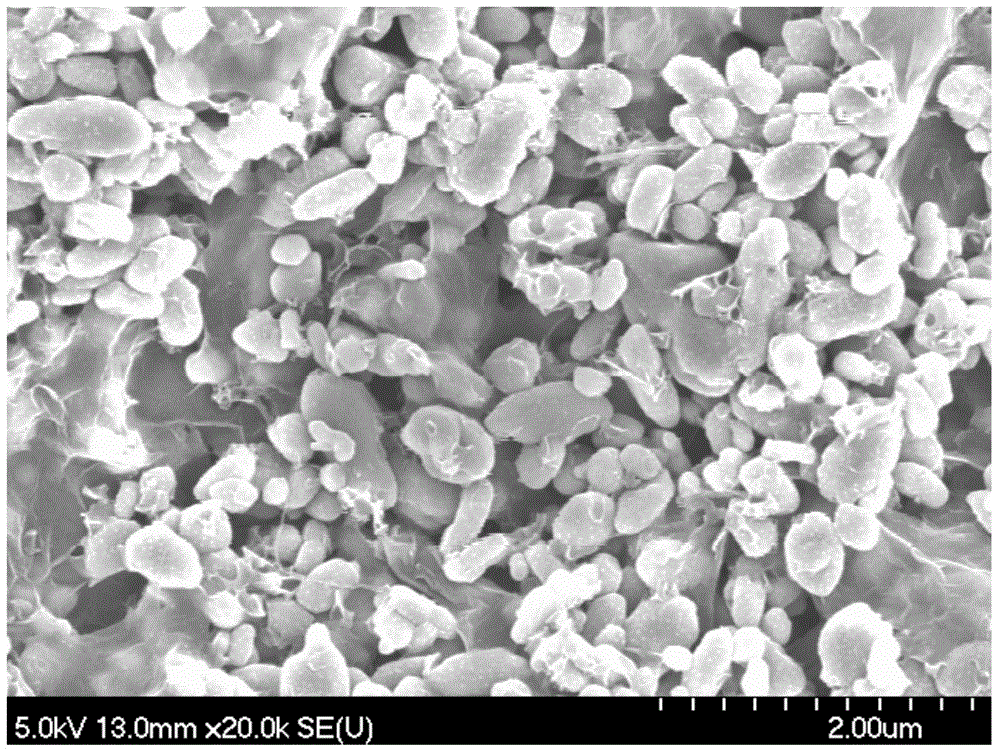

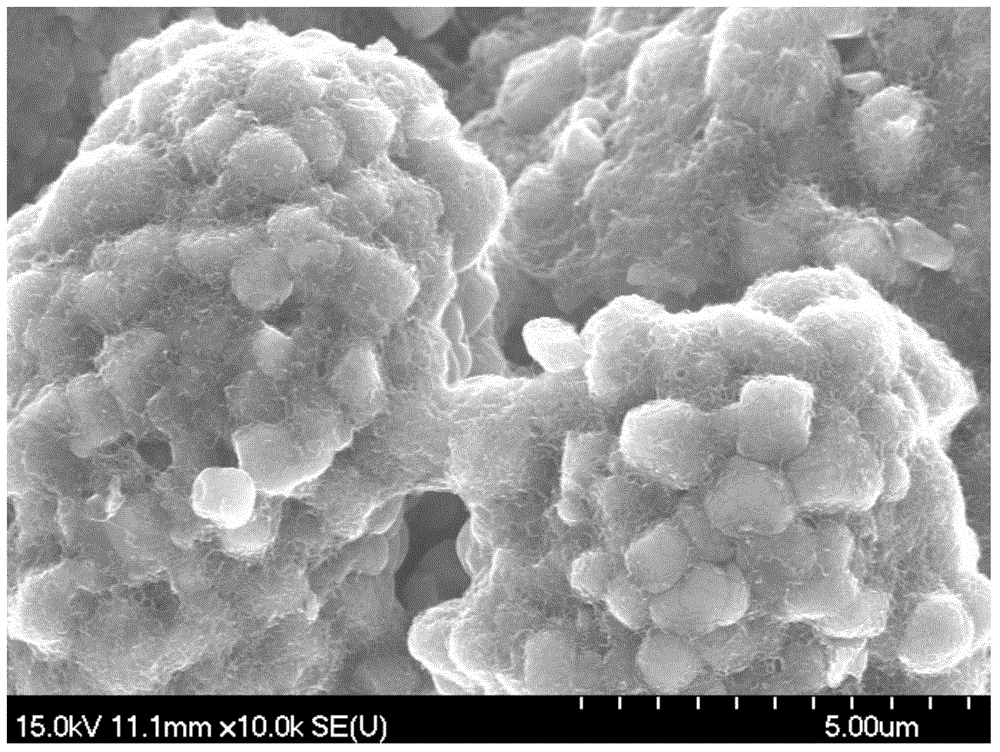

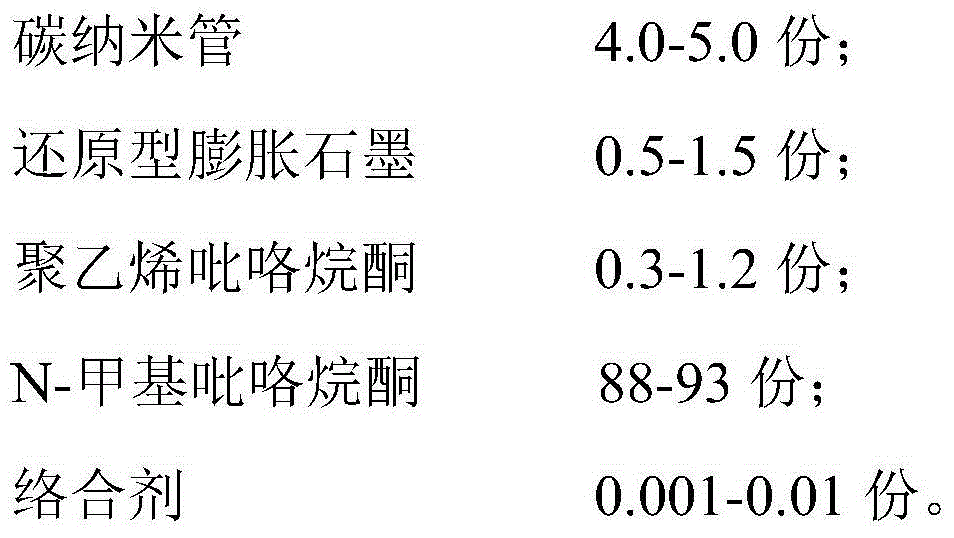

Composite conductive paste for anodes and cathodes of lithium ion batteries as well as preparation method for composite conductive paste

ActiveCN104795570AImprove chemical performanceLarge capacityElectrode manufacturing processesSecondary cellsHigh energySodium-ion battery

The invention belongs to the technical field of lithium ion batteries, and provides composite conductive paste for anodes and cathodes of the lithium ion batteries as well as a preparation method for the composite conductive paste. The composite conductive paste comprises the following ingredients in parts by weight: 4.0-5.0 parts of carbon nanotubes, 0.5-1.5 parts of reduced expanded graphite, 0.3-1.2 parts of polyvinylpyrrolidone, 88-93 parts of N-methyl pyrrolidone and 0.001-0.01 part of a complexing agent. The composite conductive paste can be combined with active substances to form a favorable conductive network, so that the lithium ion batteries have such electrochemical properties as long cycle life and high energy density.

Owner:卡博特高性能材料(珠海)有限公司

Environment-friendly converter bedding-face repairing material and preparation method thereof

The invention discloses an environment-friendly converter bedding-face repairing material and a preparation method thereof. The repairing material comprises the following ingredients by weight percent: 30 to 65 percent of sintering magnesium sand, 10 to 45 percent of waste magnesite-chrome bricks, 1 to 10 percent of asphalt powder, 5 to 15 percent of tar, 1 to 5 percent of ethanol, 1 to 5 percent of N-methyl-2-pyrrolidinone and 0 to 5 percent of o-xylene. The preparation method comprises the following steps: 1) pre-crushing the sorted sintering magnesium sand and recycled waste magnesite-chrome bricks; 2) uniformly mixing the pre-crushed sintering magnesium sand and waste magnesite-chrome bricks to obtain a mixed coarse material; 3) finely crushing the mixed coarse material to obtain a mixed fine material; 4) uniformly mixing the mixed fine material and asphalt powder in a stirring machine; 5) adding tar, ethernol, N-methyl-2-pyrrolidinone and o-xylene, and stirring the mixture for 10 to 25 minutes. The practices prove that the converter repairing material has good mobility, can be sintered easily, has long service life and generates little smoke when sintered.

Owner:武汉钢铁有限公司

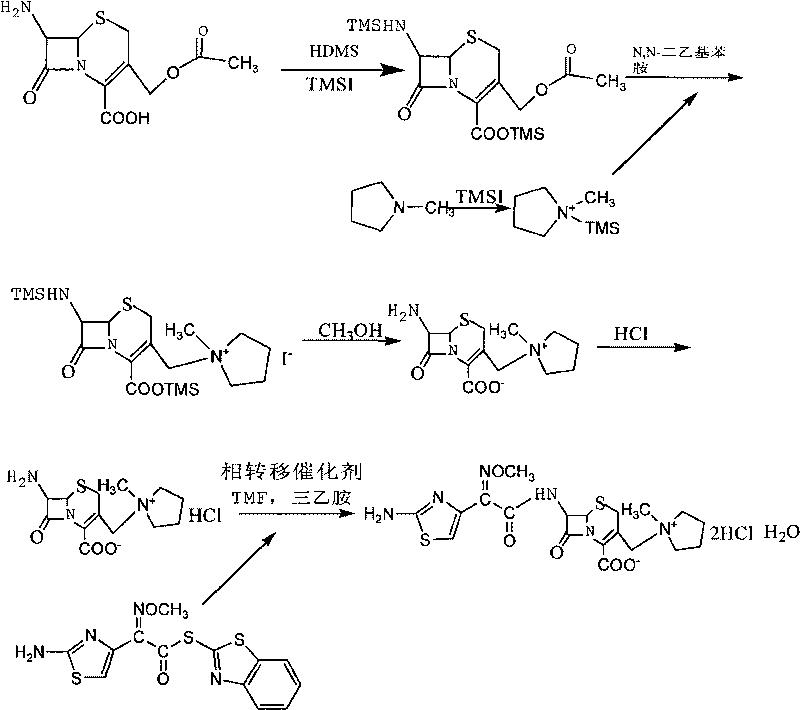

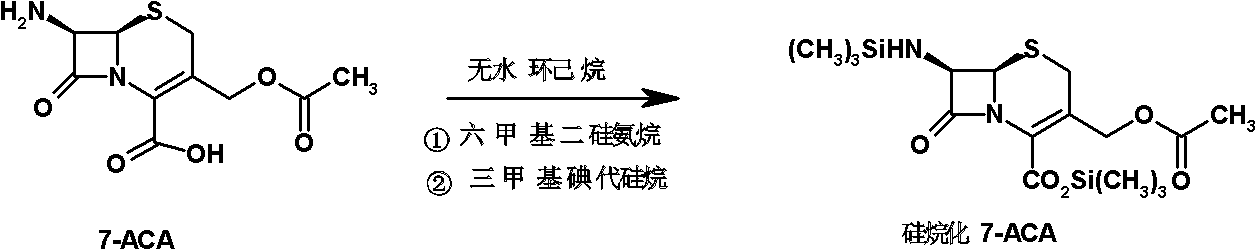

Method for synthesizing cefepime hydrochloride

InactiveCN101735251AHigh densityHigh reactivityAntibacterial agentsOrganic chemistryCefepime hydrochlorideVolumetric Mass Density

The invention relates to a method for synthesizing cefepime hydrochloride. The method comprises the following steps: taking 7-aminoce-phalosporanic acid (7-ACA) and N-methylpyrrolidine as raw materials, firstly, carrying out carboxylic and amino protection on the 7-ACA by HMDS, then preparing the N-methylpyrrolidine and iodotrimethylsilane into a quaternary ammonium salt intermediate, finally, adding the intermediate into the protected 7-ACA solution and reacting to prepare 7-MPCA; taking the 7-MPCA and AE-active ester, adding a phase transfer catalyst into an organic phase for carrying out an N-acidylating reaction, salifying and reacting to obtain the cefepime hydrochloride. The invention has the main characteristics that the quaternary ammonium salt intermediate is prepared in the step (1), the defects of high electron cloud density, strong reactivity and many side reactions of the N atom of N-methyl pyrrole are overcome, the yield is enhanced by 7%, and the product purity is enhanced. During the N-acidylating reaction in the organic phase in the step (2), the phase transfer catalyst is added, so that the conversion rate of the reaction is enhanced by 5%, and the product yield is enhanced.

Owner:YIYUAN XINQUAN CHEM

Method for synthetizing aqueous polyurethane emulsion from package waste PET bottles

The invention relates to a method for synthetizing aqueous polyurethane emulsion from package waste PET bottles. The aqueous polyurethane emulsion comprises the following raw components in parts by weight: 17 parts of isophorone diisocyanate, 32 parts of polypropylene glycol, 3.5 parts of dimethylolpropionic acid, 2.5 parts of waste PET alcoholysate, 5 parts of triethylamine, 7 parts of N-methyl pyrrolidone, 8 parts of acetone, 70 parts of deionized water and 0.5 part of dibutyltin dilaurate. The method disclosed by the invention has the advantages that the waste PET bottles are subjected to alcoholysis to generate waste PET alcoholysate with hydroxyl reaction activity, and the waste PET alcoholysate serves as a small molecule chain extender in the aqueous polyurethane emulsion synthetizing to participate in the chain extension reaction of aqueous polyurethane prepolymer, so that the waste PET alcoholysate is successfully grafted on the aqueous polyurethane molecular chain and the aqueous polyurethane emulsion with excellent performances is synthetized; the increasingly serious environmental pollution problem brought by the waste package polymer PET bottles is solved.

Owner:XIAN UNIV OF TECH

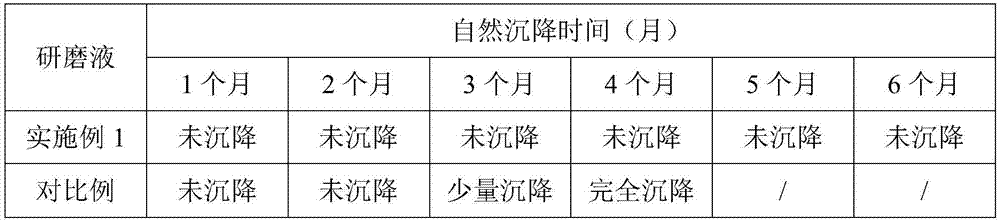

Aqueous diamond grinding fluid with continuously suspending abrasives and preparation method thereof

ActiveCN105440953AHinder sedimentationImprove ease of useOther chemical processesPolishing compositions with abrasivesAlkylphenolPolyurea

The present invention discloses an aqueous diamond grinding fluid with continuously suspending abrasives and a preparation method thereof, and belongs to the technical field of precision and ultra precision grinding processing. The grinding fluid comprises the following components in parts by weight: 0.1-5 parts of diamond abrasives, 0.01-2 parts of alkylphenol polyoxyethylene ether, 1-5 parts of modified polyurea N-methylpyrrolidone, 1-5 parts of N-methylpyrrolidone, 30-60 parts of an organic solvent, and 23-67.89 parts of water. According to the preparation method disclosed by the present invention, by using a surface modifying method, the diamond abrasives are modified by the alkylphenol polyoxyethylene ether, the modified diamond abrasives can be stably adsorbed on a molecular chain of the modified polyurea N-methylpyrrolidone; the bonding force between two is enhanced; meanwhile, by using the spatial network structure of a modified polyurea N-methylpyrrolidone molecule, the diamond abrasives are prevented from settling and aggregating to realize continuous suspending of the diamond abrasives, so that uniformly mixing operation before using the grinding fluid is saved, and the convenience in use is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

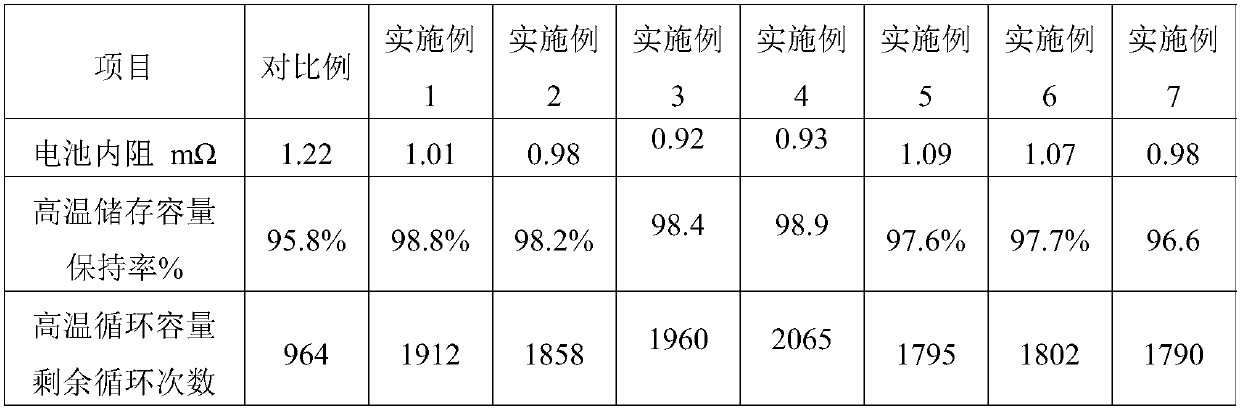

Lithium ion battery electrolyte solution

InactiveCN107749493ALower internal resistanceImprove high temperature storageSecondary cellsPolyethylene glycolSolvent

The invention discloses a lithium ion battery electrolyte solution, and relates to the technical field of manufacturing of lithium ion batteries; the lithium ion battery electrolyte solution comprisesa lithium salt, a solvent, vinylene carbonate, an additive A and an additive B; the additive A is an ether nitrile compound or an aromatic compound, and the additive B is an organic ammonium salt; the ether nitrile compound is one of tetraethylene glycol dimethyl ether, ethylene glycol monobutyl ether, butanedinitrile or 1,3,6-hexanetricarbonitrile, the aromatic compound is one of thiophene, N-methylpyrrole or o-terophenyl, and the organic ammonium salt is ammonium benzoate or methyl ammonium benzoate. Based on the conventional additives, the combined additive of ether nitrile, the aromatic compound and the organic ammonium salt is added, a low-impedance, thin and dense SEI film is formed, and the battery internal resistance, the rate performance and the low-temperature performance are improved.

Owner:WANXIANG 123 CO LTD +1

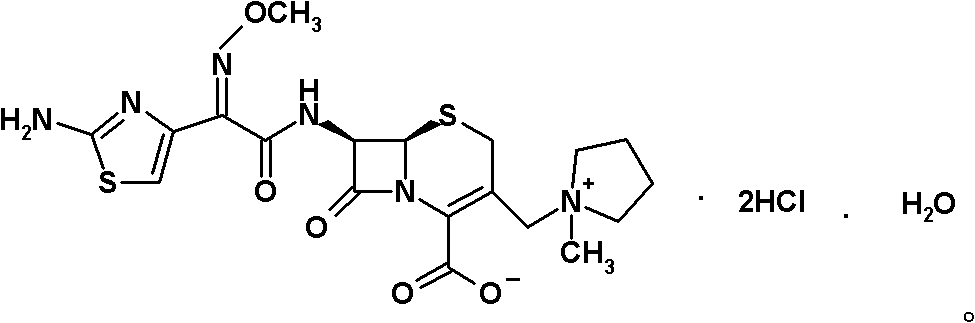

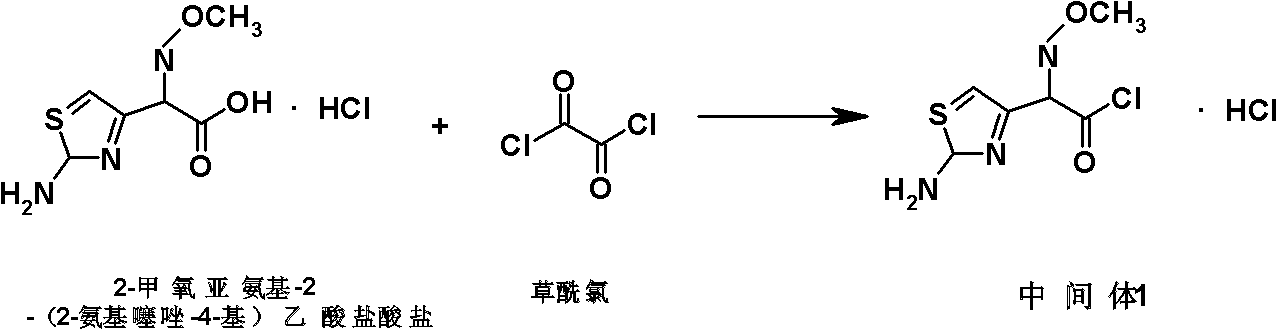

Preparation method of cefepime hydrochloride

ActiveCN101935325ASimple processAvoid the phenomenon of inhomogeneous crystal form and poor fluidityOrganic chemistryCefepime hydrochlorideBetaine

The invention discloses a preparation method of cefepime hydrochloride, comprising the following steps of: reacting oxalyl chloride with 2-methoxyimino-2-(2-aminothiazole-4-yl) acetic acid hydrochloride to obtain a midbody I, i.e. 2-methoxyimino-2-(2-aminothiazole-4-yl) acetyl chloride hydrochloride; mixing silanized 7-aminoce-phalosporanic acid and silanized N-methylpyrrolidine, and reacting to obtain a midbody II, i.e. hydriodic acidification (6R, 7R)-7-amino-3-[(1-methyl-1-tetrahydro pyrrolidine) methyl]-3-cephem-4-formic betaine, in the presence of trimethyl idodine silicon hydride, isopropanol and an aqueous solution of hydrogen iodide; dissolving the midbody II into dichloromethane, sequentially adding trimethylchlorosilane and hexamethyldisilazane for reaction, and then adding the midbody I and triethylamine to react to prepare the cefepime hydrochloride. The cefepime hydrochloride prepared by the method has the advantages of uniform crystal form, good flowability and simple process and is suitable for industrialized production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

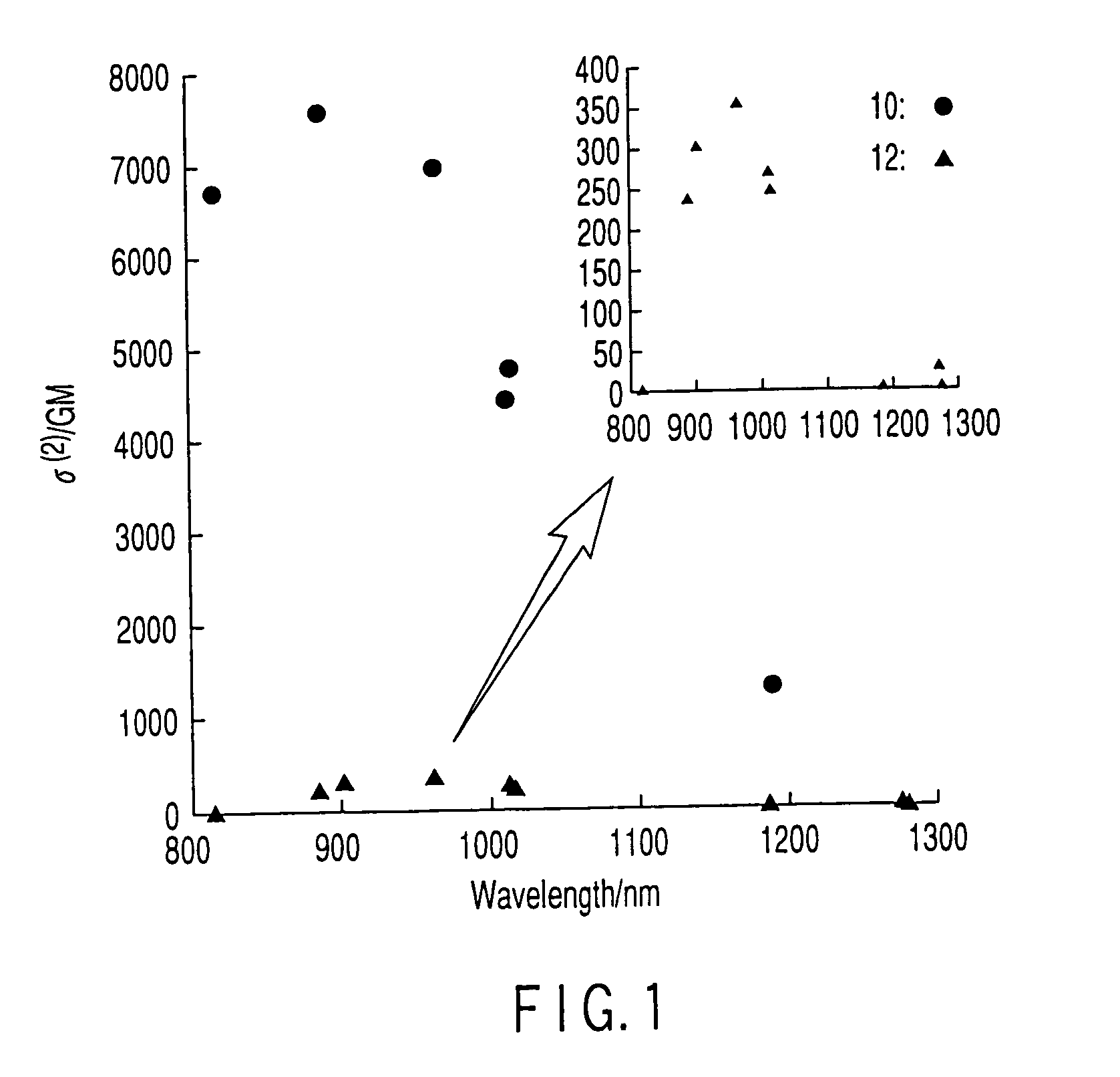

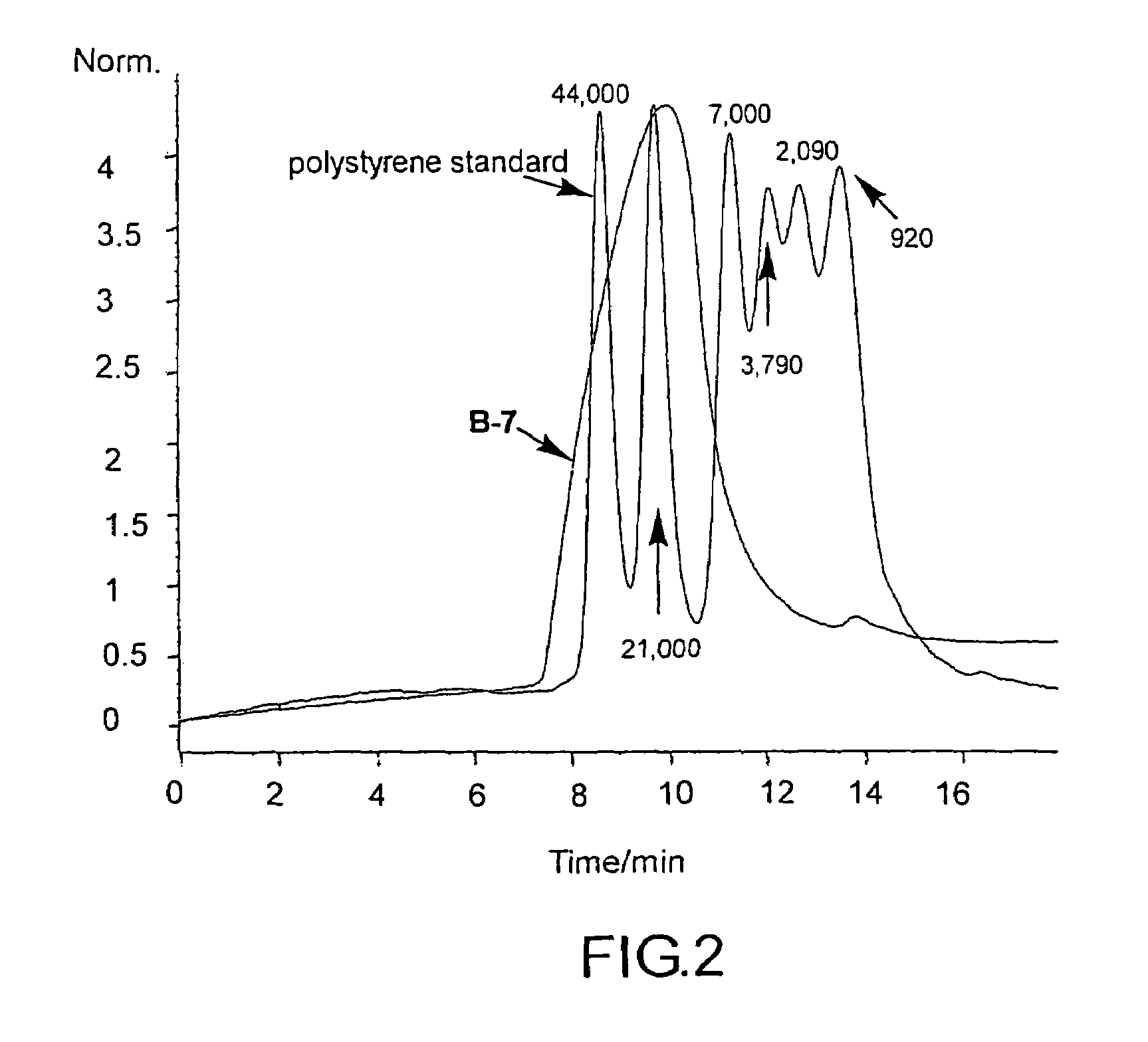

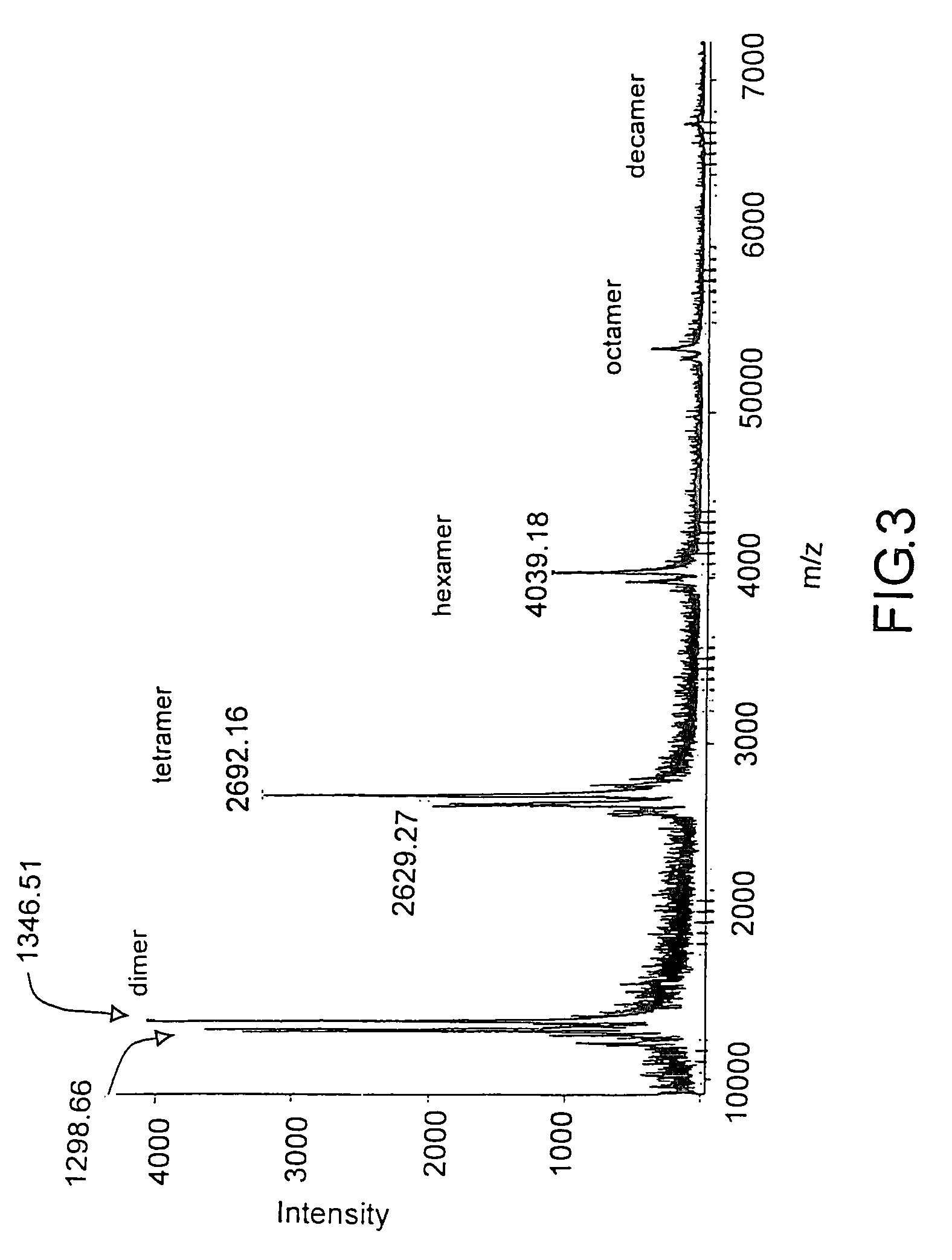

Porphyrin array exhibiting large two photon absorption property and including, as structural unit, bis (imidazolylporphyrin metal complex) linked with acetylenic bond and the derivative thereof, and method of producing the same

InactiveUS7022840B2Big absorptionUltrasonic/sonic/infrasonic diagnosticsBiocidePorphyrinMethyl group

A porphyrin array exhibiting a large two-photon absorption property, and being linked with an acetylenic bond(s), represented by the following formulas: wherein R1 represents an alkyl or aryl group, M1 represents a metal ion capable of serving as a core metal and forming a coordinate bond with Im, M2 represents two protons or a metal ion incapable of forming a coordinate bond with Im, R2 and R3 represent a group selected from a porphyrin residue or porphyrin metal complex residue, a cyclic diimide residue, a dialkylviologen residue, a benzoquinone residue, an N-methylpyrrolidine-fullerene derivative residue and a ferrocene residue, Im is represented by Im1 or Im2: (R8 represents methyl or H), L1 represents —(—C≡C—)m— (m=1 to 3); n represents an integer of 1 or more; R9 represents one of R1, R2, R3 and Im.

Owner:NARA INSTITUTE OF SCIENCE AND TECHNOLOGY

Special cleaning agent of environment-friendly water-based circuit board and preparation method of special cleaning agent

ActiveCN103834484ANo damageUnique in natureNon-ionic surface-active compoundsOrganic detergent compounding agentsWater basedActive agent

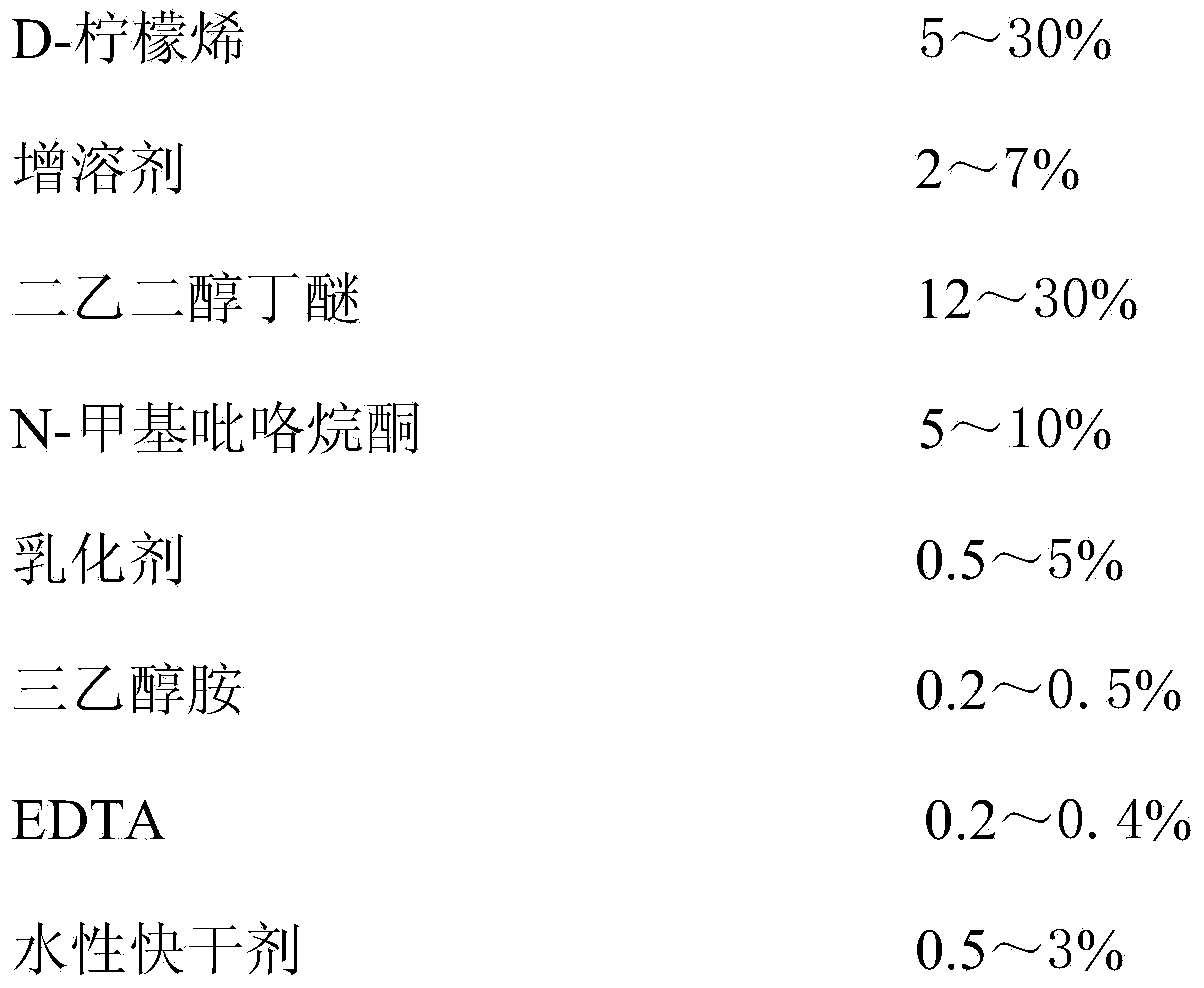

The invention discloses a special cleaning agent of an environment-friendly water-based circuit board and a preparation method of the special cleaning agent. The special cleaning agent comprises the following components in weight percentage: 5%-30% of D-limonene, 2%-7% of a solubilizer,12%-30% of butyl cellosolve, 5%-10% of N-methyl pyrrolidone, 0.5%-5% of an emulsifying agent, 0.2%-0.5% of triethanolamine, 0.2%-0.4% of EDTA (Ethylene Diamine Tetraacetic Acid), 0.5-3% of a water-based quick-drying agent, 1.5%-4% of an addition agent and 20%-60% of deionized water. The special cleaning agent disclosed by the invention has the advantages that an environment-friendly requirement is met, the cleaning efficiency is high, and the special cleaning agent is suitable for rapidly cleaning resins, scaling agents, welding agents, thixotropic agents, thickening agents, active agents and other pollutants on the surfaces of various electronic circuit boards; the using temperature is 25 DEG C-38DEG C, and the special cleaning agent is directly cleaned under normal temperature and is also suitable for cleaning an ultrasonic washing machine.

Owner:荣晖电子(惠州)有限公司

Waterborne polyurethane emulsion coating and method for preparing same

InactiveCN101709198AHigh molecular weightGood yellowing resistancePolyurea/polyurethane coatingsPolyesterSolvent

The invention relates to a waterborne polyurethane emulsion coating and a method for preparing the same. The coating comprises the following components in percentage by weight: 20 to 40 percent of isophorone diisocyanate, 20 to 40 percent of polyester, 5 to 10 percent of hydrophilic chain extender, 2 to 10 percent of chain extender, 1 to 3 percent of crosslinking agent, 3 to 10 percent of neutralizing agent, and 0.5 to 8 percent of N-methylpyrrolidone. The preparation process comprises the steps of: preparing raw materials, dewatering polyester, synthesizing prepolymers, neutralizing prepolymer, extending chains and emulsifying. Compared with the prior art, the method has the advantage that high-boiling point solvents in small quantity are used and acetone is not used, so that the coating does not contain residual acetone, has good temperature endurance, weather resistance, stripping property and water resistance, and can be widely applied in the field of pack coatings.

Owner:SHANGHAI CHENGYING NEW MATERIALS

Method for purifying N-methyl pyrrolidone

InactiveCN102993078AEfficient removalMeeting high-purity demandsOrganic chemistryInorganic saltsDistillation

The invention relates to a method for purifying N-methyl pyrrolidone. The method comprises the steps of (1) washing poly-p-phenylene terephthamide polymers obtained after the polycondensation through deionized water repeatedly to obtain washing liquor containing the N-methyl pyrrolidone (NMP), adding antalkali into the washing liquor to perform neutralizing treatment, and regulating PH of the solution to 6-7; (2) performing extraction separation on the washing liquor to obtain solution with an NMP-extraction agent system on the lower layer and a water-inorganic salt system on the upper layer, and performing secondary extraction on the water-inorganic salt system on the upper layer; and (3) adding an organic solution with an isocyanic acid functional group into a crude product of the NMP, and performing filtering and distillation to obtain the high-purity NMP. By means of the method, the purity of the finally-obtained NMP solvent is remarkably improved, processing procedures are simplified, accordingly, working efficiency is improved, and operability is strong. Furthermore, the purity of the NMP solvent obtained by means of purifying is higher than 99.8%, and the water content of the NMP solvent is smaller than 0.01%.

Owner:DONGHUA UNIV +1

TRPM8 receptor antagonists

Owner:DOMPE FARM SPA

Waterborne polyurethane and preparation method thereof

ActiveCN103865027AUniform performanceSolve the problem of differences in comprehensive performancePotassium hydroxidePolyethylene glycol

The invention discloses a waterborne polyurethane, comprising the following components in parts by weight: 10-17 parts of isophorone diisocyanate, 22-32 parts of polyethylene glycol, 0.5-3.5 parts of hydrophilic chain extender, 0.1-3 parts of 1,4-butanediol, 1-5 parts of potassium hydroxide, 4-7 parts of N-methyl pyrrolidone, 3-8 parts of acetone, 50-70 parts of hydrogen peroxide and 0.05-0.1 parts of dibutyltin dilaurate. According to the preparation method of the waterborne polyurethane disclosed by the invention, water is decomposed by adopting hydrogen peroxide in a reaction process while the traditional chain-extending emulsification and dispersion reaction on a waterborne polyurethane prepolymer by directly adding water are replaced, and the emulsification, chain extension, dispersion, and the like can be more evenly carried out, so that the waterborne polyurethane with balanced performance is obtained, and the problems of uneven emulsification and chain extension of water on the prepolymer, and poor overall performance of the waterborne polyurethane caused by over-large viscosity of the existing waterborne polyurethane prepolymer are solved.

Owner:蚌埠金黄山凹版印刷有限公司

Dairy cow nipple antifreezing disinfector and preparation method thereof

ActiveCN103505471AImprove stabilityHigh yieldAntisepticsPharmaceutical non-active ingredientsTectorial membranePotassium

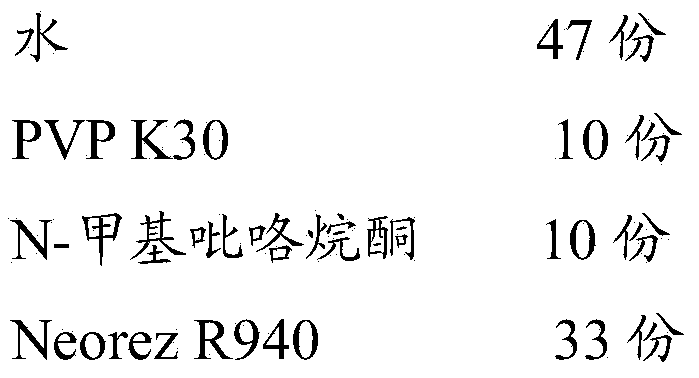

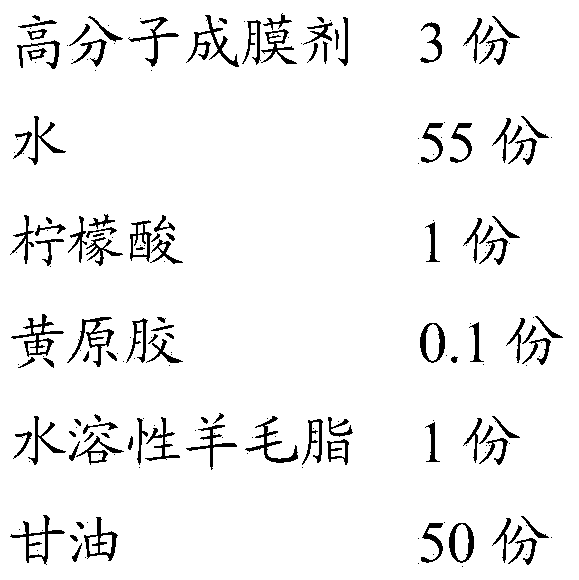

The invention discloses a dairy cow nipple antifreezing disinfector. The disinfector comprises the following ingredients in part by weight: 3-6 parts of polymer film-forming agent, 50-60 parts of water, 1-2 parts of organic acid, 0.1-1 parts of thickener, 1-10 parts of skin-friendly agent, 20-60 parts of antifreezing agent, 0.05-0.5 parts of potassium iodate, and 0.1-1 parts of potassium iodite, wherein the polymer film-forming agent comprises the following ingredients in part by weight: 40-60 parts of water, 5-15 parts of PVP (polyvinyl pyrrolidone), 5-15 parts of N-methylpyrrolidone, and 20-40 parts of waterborne polyurethane emulsion. The dairy cow nipple antifreezing disinfector can form a layer of dense membrane on the dairy cow nipple to protect the dairy cow nipple from freezing and invasion of bacteria, and the formed protecting membrane is easy to wash away. In the meantime, the invention further discloses a preparation method of the disinfector. The preparation method is simple and safe to operate, and easy for industrial production.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

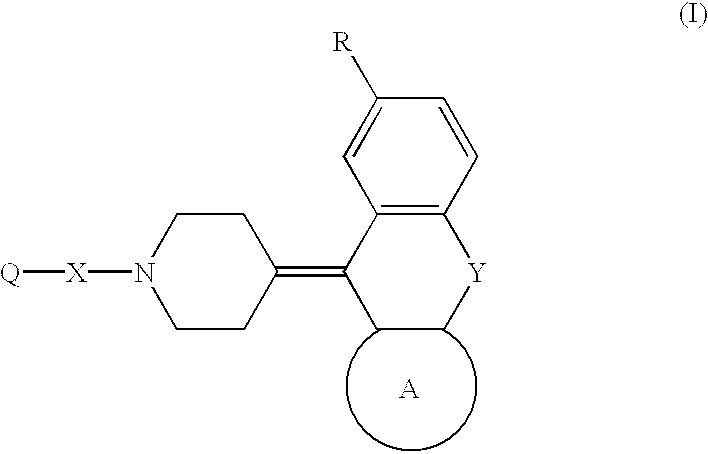

Piperidine derivatives and hypotensives containing the same

InactiveUSRE38257E1Simple preparation processLow costOrganic chemistryHydrogenTetrahydroisoquinoline

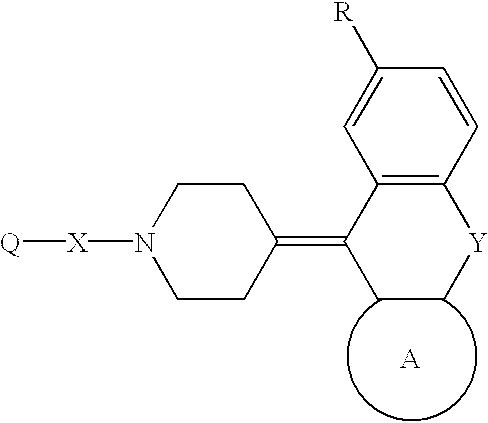

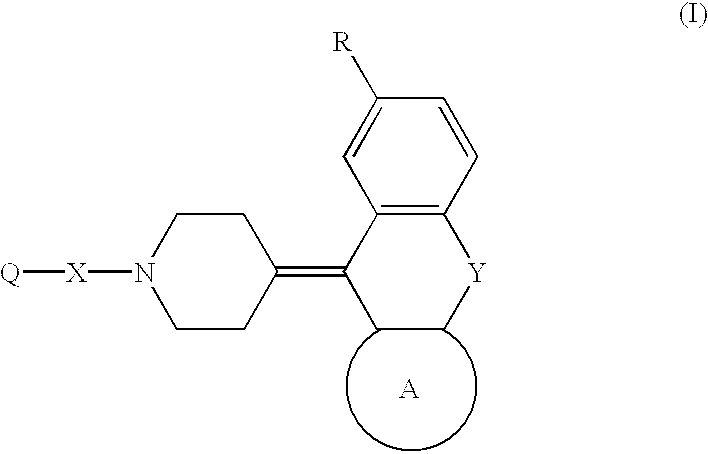

A piperidine compound of the formula (I): ##STR1## wherein A is a fused aromatic ring; R is hydrogen, chloro or methoxy; X is (CH.sub.2).sub.n, which may be substituted, in which n is 0 or an integer of 1 to 10, --CH.ident.CH--, --C.ident.C--, --O--, --S--, --NH--, --N(COCH.sub.3)--, --N(COOC.sub.2 H.sub.5)--, --N(CHO)--, --N(CH.sub.3)--, --CO--, --SO--, or --SO.sub.2 --; Y is --CH.ident.CH--, --CH.sub.2 CH.sub.2 --, --CH.sub.2 CO--, --O--, --S--, --NH--, --OCH.sub.2 --, --SCH.sub.2 --, --NHCH.sub.2 --, --CH(OH)CH.sub.2 -- or --CH(OH)CH(OH)--; and Q is substituted or unsubstituted n-hexyl, carboxypropyl, ethoxycarbonylpropyl, cyanopropyl, cyclohexyl, phenyl, indanyl, naphthyl, tetrahydronaphthyl, benzocycloheptyl, piperidinyl, tetrahydroisoquinolinyl, indolyl, pyrolyl, furyl, thienyl, thiazolyl, oxazolyl or N-methylpyrolyl, wherein any one or more of the --(CH.sub.2)-groups of the hexyl, carboxypropyl, ethoxycarbonylpropyl and cyanopropyl groups may be replaced by --CH.ident.CH--, --C.ident.C--, --O--, --S--, --NH--, --N(COCH.sub.3), --N(COC.sub.2 H.sub.5)--, --N(CHO)--, --N(CH.sub.3), --CO--, --SO-- or --SO.sub.2 --, and wherein one or more of the --(CH.sub.2)-groups in X and Q may be substituted by --(CH.sub.2).sub.4 -- or --(CH.sub.2).sub.5 -- thereby forming a ring structure.

Owner:AJINOMOTO CO INC

Long-acting sustained-release composite fertilizer comprising wood fiber

InactiveCN104130053AWide variety of sourcesGuaranteed sourceFertilizer mixturesMicrobial agentCrop yield

The invention relates to the field of composite fertilizers, and specifically relates to a long-acting sustained-release composite fertilizer comprising wood fiber. The fertilizer is prepared from the raw materials of, by weight, 10-15 parts of diatomite with a specification of 1250-2000 meshes, 10-12 parts of potassium chloride, 18-20 of ammonium carbonate, 12-15 parts of crop straws, 2-4 parts of zinc sulfate, 10-12 parts of calcium superphosphate, 3-5 parts of boron-magnesium fertilizer, 1-3 parts of ferrous sulfate, 12-13 parts of rice bran, 6-8 parts of calcium hydrogen phosphate, 6-8 parts of composted goose dung, 2-3 parts of a BGB microbial agent, 1-3 parts of xylanase, 10-12 parts of wood vinegar liquid, 1-3 parts of wood fiber with a specification of 400 meshes, 10-12 parts of cellulose acetate, 15-18 parts of N-methylpyrrolidone, 1-2 parts of calcium lignosulfonate, 1-2 parts of ethyl para-hydroxybenzoate, 1-2 parts of nano-grade carbon, and 4-5 parts of an auxiliary agent. The composite fertilizer provided by the invention has wide raw material sources, and rich and multi-element nutrients. In a production process, with diatomite and a sustained-release coating agent comprising wood fiber and nano-grade carbon, dual coating can be formed upon the nutrients. The composite fertilizer has excellent and long-lasting sustained-release control capacity, and water-retention and drought-resistant capacities. The fertilizer effect is more long-lasting, and the fertilizer is green and highly efficient. With the fertilizer, crop yield and quality can be substantially improved.

Owner:HEFEI CHANGRUN AGRI TECH

Anti-carbonization concrete tubular pile and preparation method therefor

The invention discloses an anti-carbonization concrete tubular pile and a preparation method therefor. The anti-carbonization concrete tubular pile consists of the following raw materials in parts by weight: 10-16 parts of light calcium carbonate, 1-2 parts of wool grease, 0.7-2 parts of sodium lauroyl sarcosine, 20-30 parts of potassium feldspar powder, 3-4 parts of n-methyl pyrrolidone, 500-640 parts of ordinary silicate cement, 300-400 parts of yellow ground, 200-300 parts of gravels, 7-14 parts of a polycarboxylate water reducer, 0.1-0.2 part of dibenzoyl peroxide, 5-6 parts of maleic anhydride, 2-3 parts of polyethylene glycol monoethylether, 0.7-2 parts of sp-80, 50-70 parts of waste rubber powder, 0.1-0.2 part of triethylamine, 16-20 parts of polyethylene wax and 2-4 parts of polyvinyl butyral. The anti-carbonization concrete tubular pile can reduce quantity of harmful holes and defects in a concrete structure, reduces alkalinity of hydration products and promotes low-strength hydration products to transform into high-strength hydration products.

Owner:安徽三环管业有限公司

Nano modified polyurethane adhesive and preparation method thereof

InactiveCN102942893AGood storage stabilityHigh solid contentNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

Owner:苏州井上高分子新材料有限公司

Lithium battery positive pole slurry containing Ketjen superconducting carbon black, as well as preparation method and application thereof

InactiveCN102456883AReduce dosageNot easy to fall offCell electrodesLithium iron phosphatePole piece

The invention discloses lithium battery positive pole slurry containing Ketjen superconducting carbon black, as well as a preparation method and application thereof. The lithium battery positive pole slurry comprises the following components in parts by weight: 80 parts of lithium iron phosphate positive pole active material, 1-10 parts of Ketjen superconducting carbon black, 5-20 parts of polyvinylidene fluoride, and 500-1100 parts of N-methyl-2-pyrrolidone. The preparation method comprises the following steps of: mixing and dispersing the Ketjen superconducting carbon black and polyvinylidene fluoride bonder bonder, then adding the lithium iron phosphate positive pole active material, mixing and dispersing, pouring the slurry into a sand mill to be milled, and obtaining the lithium battery positive pole slurry containing the Ketjen superconducting carbon black. According to the invention, the problem that a pole piece is dropped off because the lithium battery positive pole slurry uses the Ketjen superconducting carbon black is solved, the dosage of conductive additive is small, the dried positive pole material is not easy to drop off, and the specific capacity of the lithium battery material is improved.

Owner:SHANGHAI HUAMING HI TECH GRP

Aluminum alloy quenching medium and preparation method thereof

The invention discloses an aluminum alloy quenching medium. The invention is characterized in that the quenching medium is prepared from the following raw materials in parts by weight: 0.5-1 part of N-methylpyrrolidone, 3-5 parts of sodium chloride, 0.5-1 part of lauric acid, 0.5-1 part of lauroyl diethanolamine, 1-2 parts of mannitol, 2-4 parts of glycerol, 1-2 parts of urea, 0.5-1 part of sodium carboxymethyl cellulose, 0.5-1 part of sodium bicarbonate, 0.3-0.5 part of sodium lignosulfonate, 1-2 parts of water-soluble lanolin, 3-5 parts of assistant and 70-80 parts of water. The quenching medium satisfies the deep quenching requirements; the treated workpiece has the advantages of high hardness, favorable tensile property and long service life; and the quenching medium effectively prevents cracking and is suitable for aluminum alloy quenching.

Owner:安徽东星汽车部件有限公司

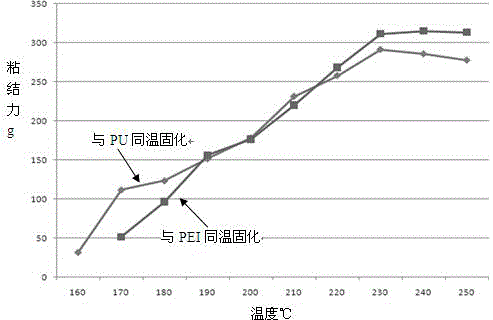

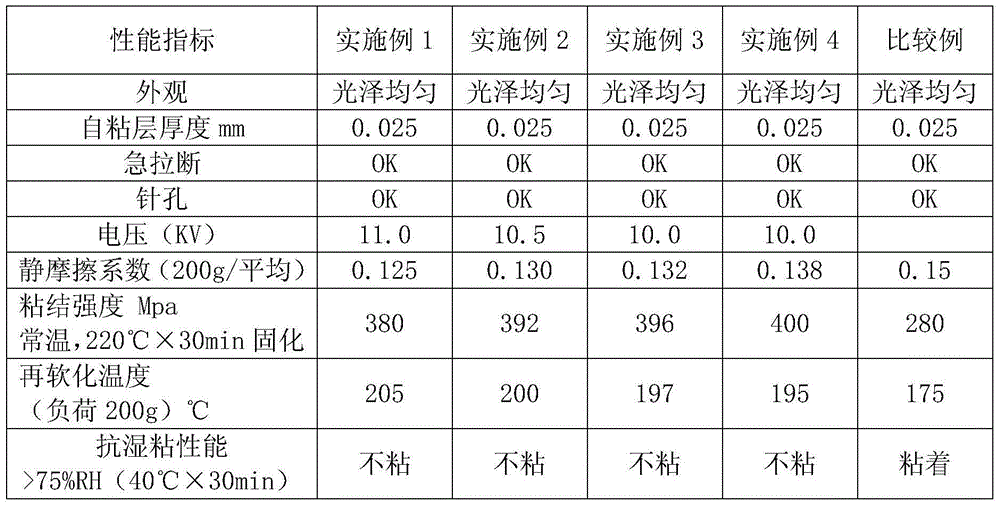

Heat-resistant self-adhesive enamelled wire paint and preparation method thereof

ActiveCN104559752AHigh bonding strengthGood deformation resistanceEpoxy resin coatingsEpoxyPolyetherimide

The invention relates to heat-resistant self-adhesive enamelled wire paint. The heat-resistant self-adhesive enamelled wire paint disclosed by the invention comprises the following raw materials in parts by weight: 160-350 parts of dimethylbenzene, 430-620 parts of N-methylpyrrolidone, 169-191 parts of polyetherimide resin, 10-18.3 parts of boron phenolic resin, 19-33.8 parts of phenol formaldehyde epoxy resin, and 0.2-0.3 part of a slipping agent. The heat-resistant self-adhesive enamelled wire paint disclosed by the invention has good heat resistance and wet-sticky-resistant property, and can meet production requirements under high-temperature and high-humidity weather conditions.

Owner:江苏佳禾电子材料有限公司

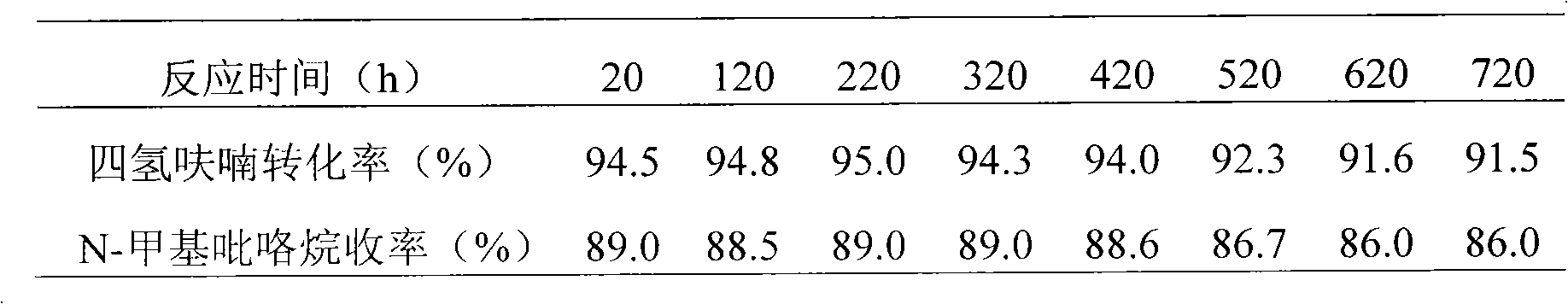

Catalyst for catalytic synthesis of N-methylpyrrolidine and application thereof

InactiveCN101912779AEasy to makeReaction raw materials are cheap and easy to obtainOrganic chemistryMolecular sieve catalystsMolecular sieveChemical industry

The invention relates to technology for synthesizing an intermediate in the medicinal and chemical industry, in particular to a catalyst for catalytic synthesis of N-methylpyrrolidine and a synthesis method thereof. The catalyst consists of a carrier and a catalytic activity component, wherein the carrier is a gamma-Al2O3 or HZSM series molecular sieve; the catalytic activity component is a simple substance of metal M or an oxide thereof; the catalytic activity component accounts for 0.5 to 20 percent of the total weight of the catalyst; and the granular size of the catalyst is 4 to 20 meshes. The catalyst is prepared by a kneading and extruding method or a dipping method. The catalyst has the advantages of simple preparation, low price of raw materials and easy purchase; and when used the catalytic synthesis of N-methylpyrrolidine, the catalyst has the advantages of mild catalytic reaction condition, low three-wastes and no pollution, wherein the conversion rate of tetrahydrofuran is substantially kept over 80 percent and the yield of the N-methylpyrrolidine is substantially kept over 60 percent.

Owner:HEBEI UNIV OF TECH

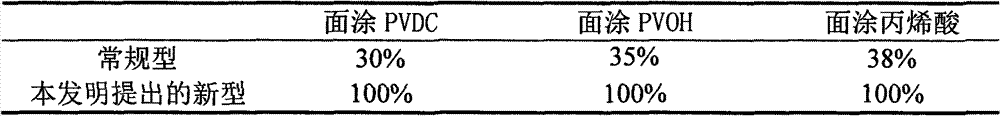

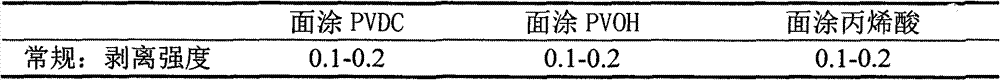

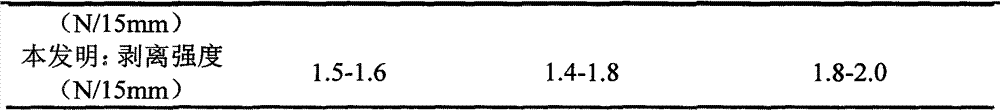

Waterborne polyurethane primer for coating plastic film and preparation method thereof

The invention relates to a waterborne polyurethane primer for coating a plastic film. The primer is prepared from the following raw materials in percentage by weight: 8 to 10 percent of diisocyanate, 12 to 16 percent of polyester polyol, 1 to 2.7 percent of hydroxycarboxylic acid compound, 2.3 to 4.2 percent of N-methyl ketopyrrolidine, 0.05 to 0.19 percent of preservative, 0.1 to 1.25 percent of chain extender, 1 to 3.13 percent of neutralizer and 73.9 to 80.7 percent of deionized water. Compared with the conventional waterborne polyurethane primer, the waterborne polyurethane primer has the advantages that after the waterborne polyurethane primer and a functional coating are coated sequentially, the waterborne polyurethane primer is high in bonding force (which can reach 2N / 15mm), attractive in appearance, environment-friendly and safe, does not contain solvent residues and is particularly suitable for the field of coated films, and the adhesive force of the coating is high.

Owner:HAINAN SHINER IND

Scavenger for outdoor adlet

The invention discloses a scavenger for outdoor adlet. The scavenger for the outdoor adlet consists of the following components in parts by weight: 20 to 40 parts of dichloromethane, 15 to 25 parts of dichloroethane, 15 to 25 parts of tributyl phosphate, 15 to 20 parts of phenol, 2 to 4 parts of N-methylpyrrolidone, 15 to 25 parts of formic acid, 2 to 6 parts of nonylphenol polyoxyethylene ether and 0.2 to 0.8 part of butylcellosolve. The scavenger for the outdoor adlet can be prepared by stirring and mixing the components uniformly. After the scavenger for the outdoor adlet is sprayed on the surfaces of walls, glass, cement rods and the like polluted by the adlet, the adlet can be eliminated by brushing with a brush and washing with clean water, so primer is not damaged, the washing speed is high, and the surfaces are clean as new after washing.

Owner:SHANGHAI JIAHUA ADVERTISEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com