Waterborne polyurethane and preparation method thereof

A water-based polyurethane and prepolymer technology, which is applied in the preparation of water-based polyurethane and the field of water-based polyurethane, can solve the problems of water-based polyurethane comprehensive performance differences, prepolymer emulsified chain extension unevenness, high viscosity, etc., to achieve uniform dispersion of emulsified chain extension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

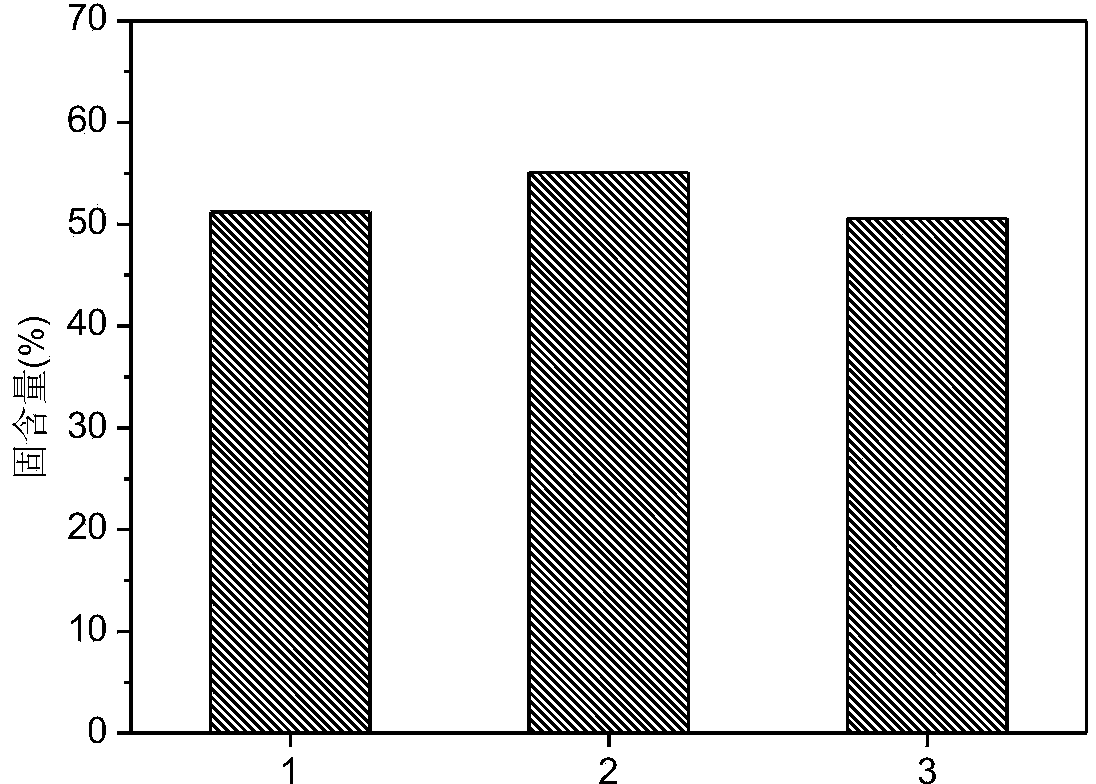

Examples

preparation example Construction

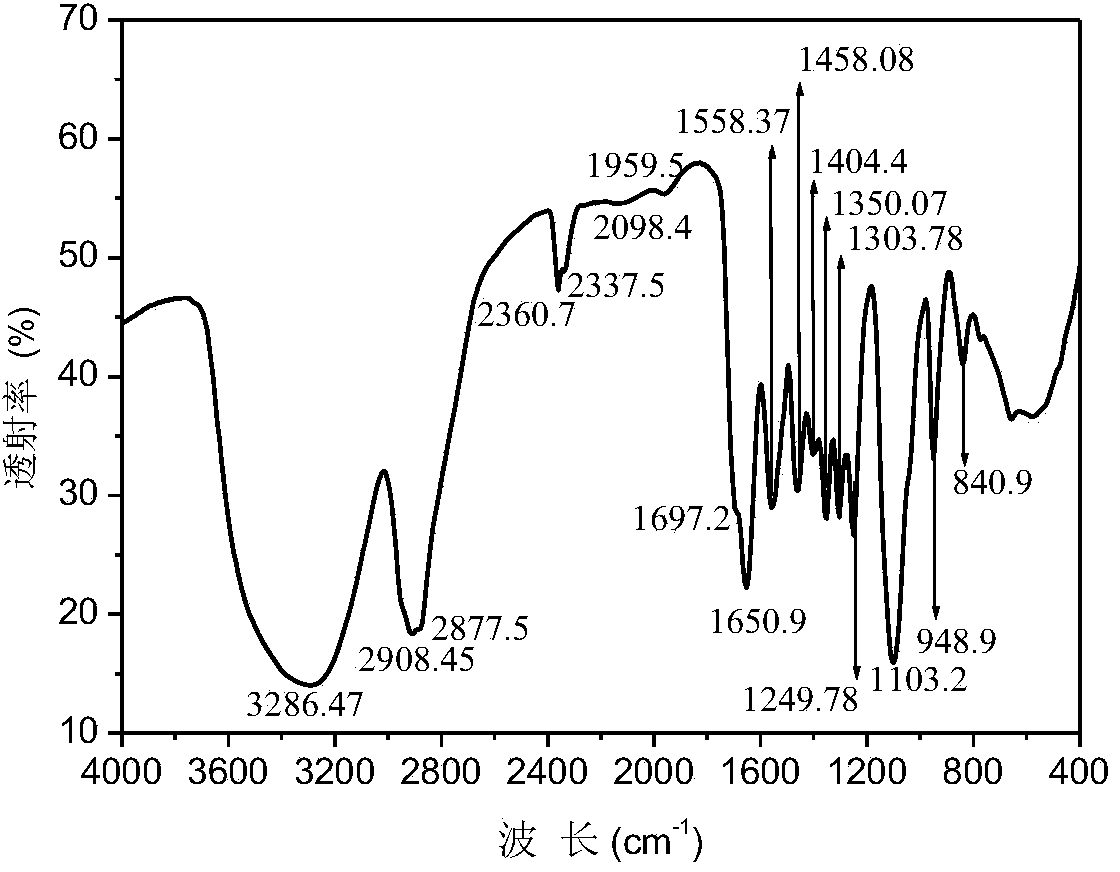

[0035] The preparation method of the water-based polyurethane of the present invention uses hydrogen peroxide to decompose water through the reaction process instead of the traditional method of directly adding water to carry out chain extension emulsification and dispersion reaction on the water-based polyurethane prepolymer, which can make the emulsification, chain extension and dispersion more uniform, and then use The pH regulator adjusts the pH value of the system to obtain waterborne polyurethane with balanced properties.

[0036] Traditional water is directly added to the water-based polyurethane prepolymer, but because of the high viscosity of the prepolymer, directly adding water will lead to uneven emulsification of the prepolymer, asynchronous chain extension reaction and uneven dispersion, resulting in the final synthesized emulsion The particle size distribution and molecular weight distribution are wide, and the viscosity of the emulsion is too high. The internal...

Embodiment 1

[0038] Step 1, weigh 10 parts of isophorone diisocyanate IPDI, 22 parts of polyethylene glycol PEG, 0.5 parts of dimethylol propionic acid DMPA, 0.1 part of 1,4-butanediol BDO, hydrogen 1 part of potassium oxide KOH, 4 parts of N-methylpyrrolidone NMP, 3 parts of acetone, hydrogen peroxide H 2 o 2 50 parts, 0.05 parts of butyltin dilaurate DBTDL;

[0039] Step 2, add IPDI and PEG to a four-necked flask with a reflux condenser, a thermometer and a stirring device, put the flask in a constant temperature water bath at 85°C and stir for 2 hours, then add DBTDL to react for 30 minutes to make IPDI and PEG adequate response;

[0040] During the reaction process, use the di-n-butylamine titration method to detect the remaining amount of isocyanate group (-NCO) in the reaction solution; when the amount of -NCO in the sample reaches the theoretical value, start to cool down;

[0041] Step 3, the temperature of the reaction solution is lowered to 50°C, DMPA is fully dispersed in NMP...

Embodiment 2

[0047] Step 1: Weigh 17 parts of isophorone diisocyanate IPDI, 32 parts of polyethylene glycol PEG, 3.5 parts of dimethylol propionic acid DMPA, 3 parts of 1,4-butanediol BDO, and potassium hydroxide according to parts by weight 5 parts of KOH, 7 parts of N-methylpyrrolidone NMP, 8 parts of acetone, hydrogen peroxide H 2 o 2 70 parts, 0.1 part of butyltin dilaurate DBTDL;

[0048] Step 2, add IPDI and PEG to a four-necked flask with a reflux condenser, a thermometer and a stirring device, put the flask in a 90°C constant temperature water bath and stir for 2 hours, then add DBTDL to react for 20 minutes to make IPDI and PEG adequate response;

[0049] During the reaction process, use the di-n-butylamine titration method to detect the remaining amount of isocyanate group (-NCO) in the reaction solution, and start to cool down when the amount of -NCO in the sample reaches the theoretical value;

[0050] Step 3, after the temperature of the reaction solution is lowered to 55°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com