Lithium ion battery electrolyte solution

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as instability, lithium-ion battery performance degradation, and poor high-temperature performance, so as to improve stability and improve battery internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

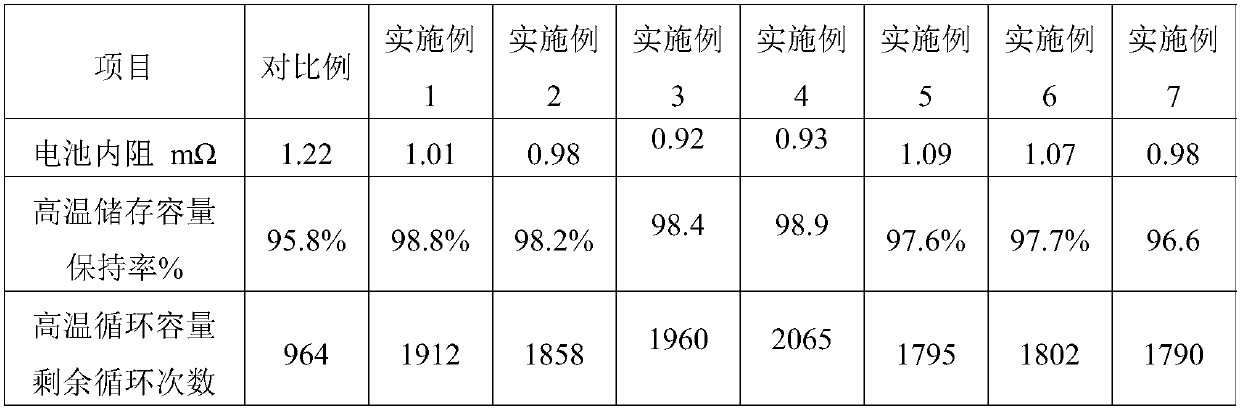

Examples

Embodiment 1

[0026] Prepare electrolyte: electrolyte comprises lithium salt, solvent, vinylene carbonate, additive A and additive B; Additive A is tetrapolyethylene glycol dimethyl ether, and its content is 0.1wt%; Additive B is ammonium benzoate , its content is 0.1wt%, and the content of vinylene carbonate is 1.5wt%; Lithium salt is lithium hexafluorophosphate, and the concentration of lithium hexafluorophosphate in electrolyte is 1.0mol / L, and solvent is dimethyl carbonate, ethyl methyl carbonate, carbonic acid The volume ratio of vinyl ester and propylene carbonate is an organic mixed solvent composed of 40:55:2:2.

[0027] Except for the electrolyte, other components and contents are the same as those in the comparative example.

Embodiment 2

[0029] Prepare electrolyte: electrolyte comprises lithium salt, solvent, vinylene carbonate, additive A and additive B; Additive A is succinonitrile, and its content is 1.5wt%; Additive B is ammonium benzoate, and its content is 1.5wt% , the content of vinylene carbonate is 1.7wt%; the lithium salt is lithium hexafluorophosphate, the concentration of lithium hexafluorophosphate in the electrolyte is 1.0mol / L, and the solvent is dimethyl carbonate, ethyl methyl carbonate, ethylene carbonate, propylene carbonate The volume ratio is an organic mixed solvent composed of 41:55:2:3.

[0030] Except for the electrolyte, other components and contents are the same as those in the comparative example.

Embodiment 3

[0032] Prepare electrolyte: electrolyte comprises lithium salt, solvent, vinylene carbonate, additive A and additive B; Additive A is thiophene, and its content is 0.5wt%; Additive B is ammonium p-toluate, and its content is 0.5wt% %, the content of vinylene carbonate is 2wt%; the lithium salt is lithium hexafluorophosphate, the concentration of lithium hexafluorophosphate in the electrolyte is 1.1mol / L, and the solvent is dimethyl carbonate, ethyl methyl carbonate, ethylene carbonate, propylene carbonate The volume ratio is an organic mixed solvent composed of 42:52:3:3.

[0033] Except for the electrolyte, other components and contents are the same as those in the comparative example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com