Catalyst for catalytic synthesis of N-methylpyrrolidine and application thereof

A methylpyrrolidine and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increased carbon deposition, increased production cost, and large hydrogen demand Quantity and other issues, to achieve the effects of mild catalytic reaction conditions, long stable life, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

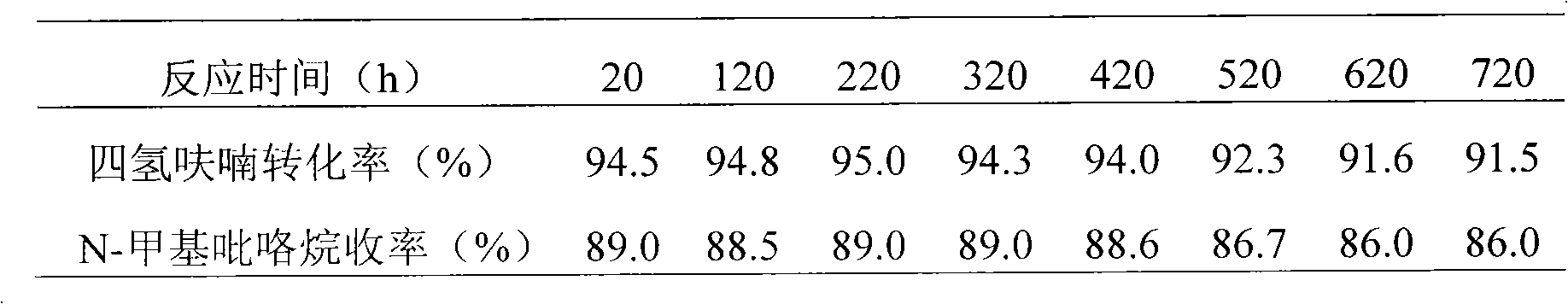

Examples

Embodiment Construction

[0014] Below in conjunction with specific example, the preparation catalyst of the present invention is described in detail:

[0015] Implementation Example 1: Preparation of Catalyst Fe / Al by Impregnation Method 2 o 3

[0016] Heat and dissolve 45g of ferric nitrate in 1200ml of deionized water, add 1000g of spherical γ-Al 2 o 3 , stirred evenly, impregnated overnight, dried in a drying oven at 110°C for 20h, and roasted in a muffle furnace at 550°C for 5h in an air atmosphere to obtain the required catalyst. The size of the catalyst is 4 mesh to 20 mesh; the weight composition of the catalyst for Fe 2 o 3 0.9%, Al 2 o 3 99.1%.

[0017] Implementation Example 2: Catalyst Ni / Al Prepared by Kneading and Extruding 2 o 3

[0018] Heat and dissolve 600g of nickel nitrate in 1000ml of 1% nitric acid aqueous solution by mass percentage, add 1000g of γ-Al 2 o 3 powder, stirred evenly, fully ground until completely mixed, extruded, dried in a drying oven at 110°C for 20 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com